Edgetech Europe GmbH, located in Heinsberg Germany, is a fully-owned subsidiary of Quanex Building Products Corporation, an industry-leading manufacturer of components sold to Original Equipment Manufacturers (OEMs) in the building products industry. Based on turnover Edgetech/Quanex is the world‘s largest manufacturer of spacers. Edgetech Europe GmbH is a sales location for the markets in continental Europe and one of the three worldwide Edgetech production plants, with a total of 480 employees and 17 extruders.

On average, worldwide, more than 300 million metres are sold annually in over 90 countries.

Easy Engineering: What are the main areas of activity of the company?

EDGETECH: Here, at Edgetech Europe, we are both a sales location and a production plant for Europe, Asia, Australia, New Zealand, Africa and the Middle East. We strongly believe in innovation by automation combined with flexible spacers. We are working hard to improve our existing warm edge spacer product Super Spacer®, but we are also working towards new products such as T-Spacer Structural Glazing for XXL format and facades. We also work a lot with automation as we believe industry 4.0 is the future of our market. That is also part of the reason we are able to produce top quality products with state of the art technology and design which is adapted to individual needs.

E.E: What the news for 2021 about new products

EDGETECH: Following the launch of the Super Spacer® T-Spacer™ SG spacer system for automated processing, Edgetech presents in 2021 the manual version for structural glazing elements and XXL formats. Both SG products are optimized for the lateral application of the primary seal. This helps with precise application down to the last millimeter of Super Spacer® during automated processing. The great advantage of this new product is that now manufacturers of free-form XXL glazing for complex structural glazing facades can ensure a more robust edge seal, regardless of whether the spacer is applied manually or automatically.

E.E: What are the ranges of products?

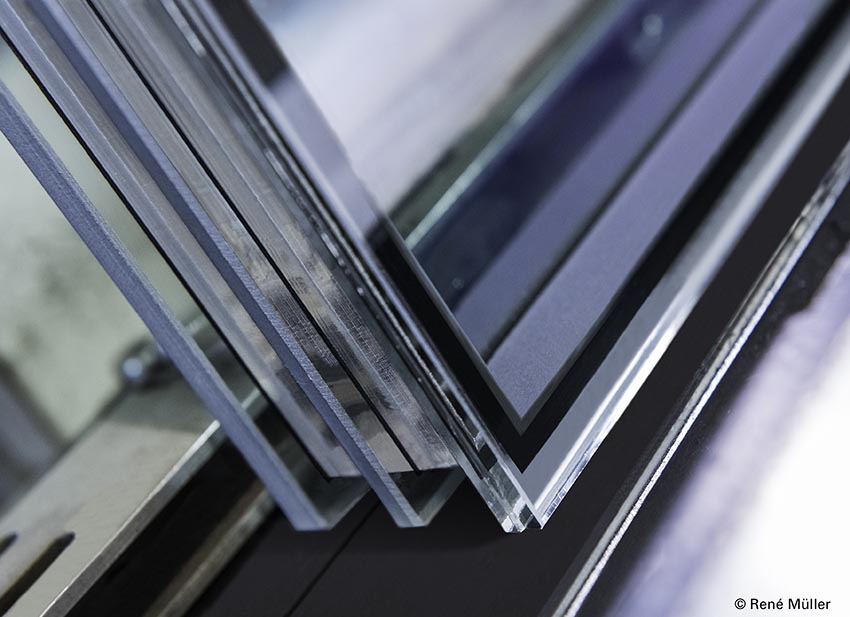

EDGETECH: Super Spacer® is a flexible, high-quality silicone material and desiccant spacer based product that delivers outstanding performance while featuring a narrow sightline as well making it aesthetic and practical for architects and designers. It has many features such as: low conductivity, a durable edge-seal, a highly breathable flexible foam matrix, a high desiccant content for moisture absorption, a high-quality silicone and a superior argon gas retention. On top of all these features, Super Spacer® has also many benefits such as a pleasing aesthetics appearance, a superior resistance to ozone, UV light and oxidation, it optimizes energy savings and enhances environmental comfort near windows, it has an excellent condensation resistance and a long-term durability.

E.E: At what stage the market where you are currently active?

EDGETECH: Warm Edge spacers are true innovation of modern days for the glass and façade industry. With low thermal conductivity, excellent Psi-values (6 Passive House Certifications!) and great condensation resistance due to the material and technique used, they are a true sustainable element for green projects. Insulating glass have become part of a new form of art that resides in today’s architecture. With great aesthetics, a unique transparence, and the ability to be shaped into any form or made into all sizes, architects are able to let their creative mind take control to create art works like. Those same Warm Edge spacers such as Super Spacer® also allow great energy efficiency within all types of buildings and help reduce carbon emissions and that is a key factor for modern construction: BREEAM certification.

E.E: What can you tell us about market trends?

EDGETECH: Customized made to measure windows have characterized the fields of window construction and insulating glass production since time immemorial. Due to intense competition and the great pressure to be efficient, a large portion of the industry has affected the transition towards industrial-style production. Last but not least, energy requirements and the trend towards large glass surfaces as well as curved and free-formed glazing are constantly presenting the industry with new challenges.

Through the use of intelligent automation, insulating glass manufacturers are capable, on the one hand, of taking advantage of the economies of scale offered by producing higher volumes and, on the other hand, of economically realizing even out of the ordinary customer requirements in batch size.

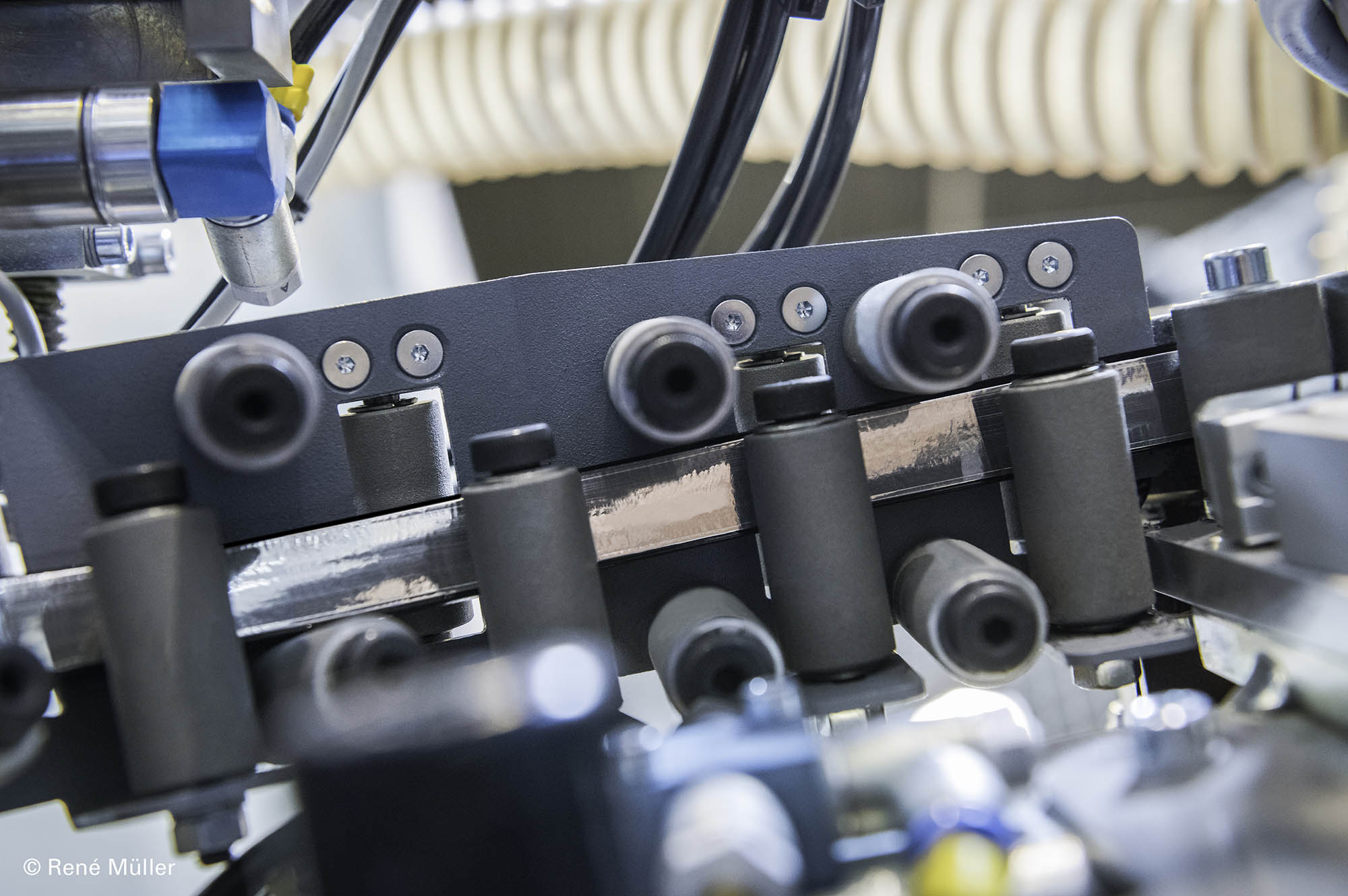

Very high levels of investment are required for activities that arise from the processing of rigid spacers, such as bending, desiccant filling or the joining of the sections, especially for small and medium-sized companies. If flexible spacers from the roll are applied automatically, the majority of set-up times are eliminated and the line is flexible to the maximum possible extent in terms of the window dimensions, glass type, number of panes and spacer width. Super Spacer® is set in parallel down to the last millimeter and guarantees a visually appealing and above all tight edge seal.

E.E: What are the most innovative products marketed?

EDGETECH: As with all products manufactured by Edgetech, Super Spacer® T-Spacer™ SG is a metal-free, silicone-based warm edge spacer made of structural foam with an integrated desiccant. It also offers excellent thermal insulation properties by virtue of its low thermal conductivity of 0.19 W/mK. The spacer’s composition offers enhanced shape memory which is very important for the long-term integrity of the edge compound. The elastic structural foam follows the climate-related movements of the glass, relieving a large proportion of the load from the butyl seal. This represents an invaluable advantage especially in climate zones with very low, very high or strongly fluctuating temperatures.

Today warm edge spacers with their low thermal conductivity, their excellent Psi-values and their excellent condensation resistance are the present and the future. Glass has become the signature material in 21st century architecture, merging from a mere functional element to a decisive structural and design element coming in many shapes and forms. At the same time improving the building energy performance and reducing carbon emissions has become vital in modern construction. Never has there been a broader range of glass solutions on the market to meet all these demands. Being unique by offering one-stop-solutions for the glazing of the building envelope is one way to stay ahead of the competition, and having a warm edge spacer system that can be efficiently and economically applied into any kind of insulating glass unit is virtually a small, but significant asset for every glass manufacturer. Architects and planners on the other hand appreciate the possibility to have one glass product with one type of spacer in a facade with varying IG units, e.g. plane and curved, XL and XS formats, or elemental cladding and structural glazing. Talking about Super Spacer® taking over the world. Here are some references that we are so proud of: the Hamburg’s Elbphilharmonie, the Vienna’s HoHo wooden skyscraper, the new Nike Flagship Store in New York, the Museum of the Future in Dubai or the Qatar National Library. XXL or XXS, round or square, there is a perfectly fitting Super Spacer® for every insulating glass window.

E.E: What estimation do you have for 2021?

EDGETECH: Since January 2021, all new buildings in the EU have to meet the standard of a “lowest energy building” and should cover their energy needs with renewable energies wherever possible. But energy efficiency is only one side of the coin when it comes to sustainable building. On the other side, the discussion about gray energy as well as the circular use of the raw materials and materials used is gaining more and more momentum.

Affordable architecture is one of the most pressing concerns of our time. However, the issues of sustainability, energy efficiency, land sealing, recycling management, comfort and social integration are contrary to the economic demands. Super Spacer® can succeed in significantly reducing the carbon footprint of buildings thanks to sustainable materials and consistent circular economy. With Super Spacer®, we offer a product that has been a leader, a Pioneer in Warm Edge Technology, for over 30 years. We aim to make the World a better, safer, cleaner place, that is why our product has an excellent Psi-value of 0.028 W/mK and has an easy 3 step process, meaning faster production times and lesser cost.