Easy Engineering: What industries do you think will grow in 2021?

EFFICIENCY SYSTEMS: I see great opportunities for companies in green technologies, information technology and sustainability.

E.E: What solutions do you provide for these industries?

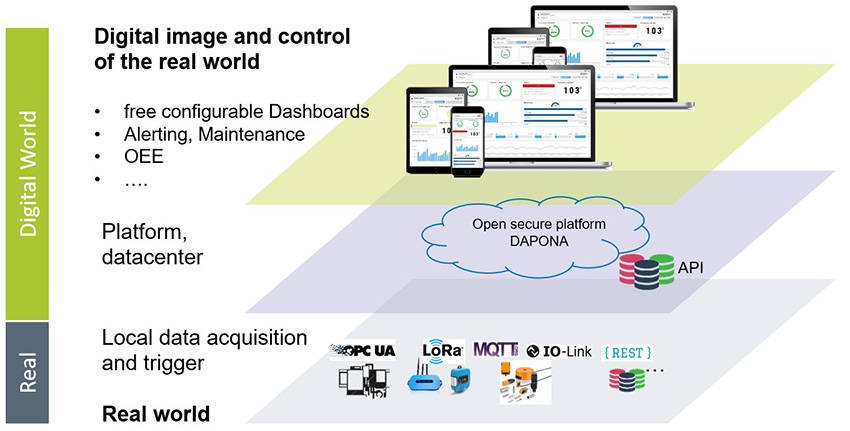

EFFICIENCY SYSTEMS: With our Industry 4.0 web service DAPONA for data visualization and alerting, we help companies achieve greater transparency and efficiency. Companies can see what is happening in reality at any time: whether it is capacity utilization in their own production (smart-shopfloor.com), damage prevention (damageavoidance.com), the monitoring and operation of machines in use by customers (machine-as-a-service.com) or benefit-based business models (pay-per-part.com): in 3 simple steps (connect, set up dashboards and get started), any digital view of processes and assets can be set up independently. Without large investments and without risk, changeable at any time.

E.E: Tell us about product innovations and what is their impact on customers?

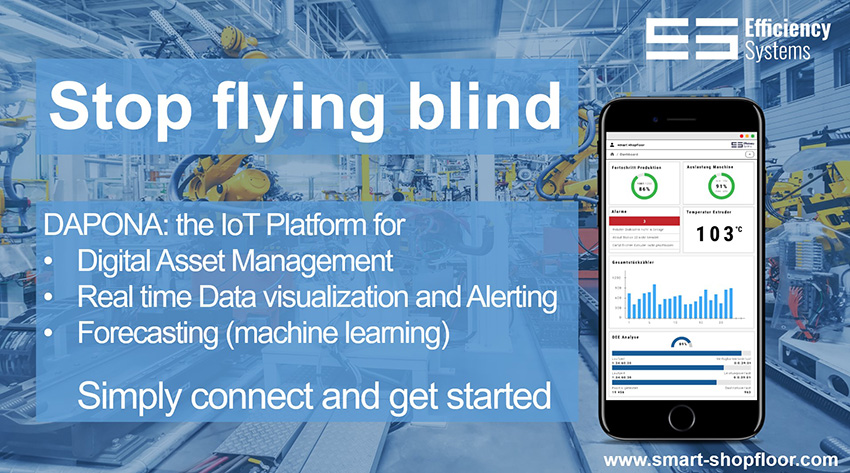

EFFICIENCY SYSTEMS: Especially in the B2B sector, many companies do not have a complete overview of their own production, let alone of their machines and systems in use by customers. They can often only react late and therefore have a high effort and unnecessary costs. DAPONA closes these two big “blind spots”: With DAPONA, companies can act early and save costs, because Dapona provides them with real-time data from their own company as well as from customers.

This is not only true for manufacturing companies. Industrial insurers are a case in point: they are recording high losses in fire insurance and are placing ever higher demands on technical fire protection, which fewer and fewer customers can afford. One of the main reasons for this is their focus on repairing damage that has already occurred as quickly as possible: smoke detectors and sprinkler systems become active when there is already a fire. However, many types of damage offer a longer phase of damage initiation. DAPONA takes advantage of this. By monitoring potential sources of damage 7/24 hours a day, DAPONA reports the first deviations long before damage occurs and helps prevent damage from occurring in the first place.

E.E: What industries do you think will grow in the future?

EFFICIENCY SYSTEMS: The use of new business models made possible by digitalization offers great growth potential for almost all industries. Up to now, product quality has been a key factor in being able to survive on the market. For example, machine manufacturers produce machines, deliver them and bill them. The important phase of machine use by the customer is often completely bypassed by the manufacturer, with the exception of service calls. In my opinion, companies will no longer differentiate themselves from the competition primarily through the quality of their products. More and more suppliers can do that today. What will count in the future is that the better manufacturers succeed in making their customers successful (e.g., producing efficiently with efficient machines), the more successful they themselves will be. Benefit-based business models (e.g., pay-per-part.com) are playing an increasingly important role here: manufacturers are becoming service providers for their customers and solving for them the central dilemma of still having to pay fixed financing costs when capacity utilization fluctuates.

E.E: What solutions do you bring for these changing industries?

EFFICIENCY SYSTEMS: Disruptive business models require a valid digital backend that provides manufacturers with real-time feedback on customer machine operating data and connects companies in data partnerships. DAPONA can be that backend: Using standard interfaces, DAPONA reads data directly from the machine controller at the customer’s site, stores it securely, and makes it available in real time to both the customer and the manufacturer for display and further processing. In addition, environmental data such as temperature or humidity can be recorded via sensors and also made available.

E.E: How will you adapt your solutions for the future?

EFFICIENCY SYSTEMS: From the very beginning, we designed DAPONA for the requirements of Industry 4.0, IoT. As a unified standard solution that can be put into operation out of the box without risk or effort through our subscription-based pricing model, we are well positioned to meet customer requirements. We will continuously expand the DAPONA base. In addition to more and more usecases that our customers set up as standard, DAPONA will also generate forecasts for the future in addition to displaying and alerting actual data based on AI.

E.E: How will these solutions benefit users?

EFFICIENCY SYSTEMS: Through DAPONA, companies and organizations can easily and quickly tap into essential elements of digitalization/IIoT without risk. DAPONA enables our customers to proceed step-by-step and intuitively. Without already having to commit to what they will need in 3 years, for example, without consulting or development, concrete problems can be solved immediately. The expansion then takes place step by step. Changes or extensions can be done simply by drag&drop and can also be changed again at any time. Without programming, special hardware or apps.

E.E: The industrial internet of things is seen as the future. What solutions do you provide and how does this impact you?

EFFICIENCY SYSTEMS: The industrial internet of things offers enormous potential. With solutions that customers can set up themselves according to their needs, DAPONA makes IIoT available in a very concrete way. DAPONA lowers costs, reduces risks and increases efficiency. In addition, DAPONA enables completely new, disruptive business models (pay-per-part.com, machine-as-a-service.com). For example, customers use DAPONA to always see the utilization in their production in real time (smart-shopfloor.com). They reduce their own costs by acting early. In addition, they equip their products with DAPONA, thereby also helping their customers to achieve greater efficiency. Still other customers monitor control cabinets with DAPONA (smart-controlcabinet.com), reduce their risk of fire and damage in the company (damageavoidance.com). In a church, DAPONA monitors temperature and humidity of the organ (smartcthedral.com) and reports deviations before it’s too late. Then we have customers who monitor in real time the quality of the engine oil in their biogas plants (smart-biogas.com) or the quality of the cooling lubricant in their CNC machines (lubricantmonitoring.com). We are currently equipping a city with soil moisture monitoring (smart-moisture.com), and report when irrigation is needed again. In another city, we monitor the public passenger elevator and report failures, as well as vandalism to rescue equipment. A restaurant will use DAPONA to reduce its dispensing losses (smart-dispense.com).

E.E: How do you think 5G will improve industrial processes?

EFFICIENCY SYSTEMS: 5G will enable dynamic industrial processes and decouple them from individual companies. Companies will be able to dynamically connect to process chains and dissolve them again at any time. Batch size 1 will become more and more possible.

More info:

https://smart-shopfloor.com/en/home/

ABOUT THE AUTHOR

Thilo Heffner (www.heffner.ch) is the founder of the startup Efficiency Systems. He has many years of practical B2B experience in how industrial software can create concrete benefits for companies and organizations.