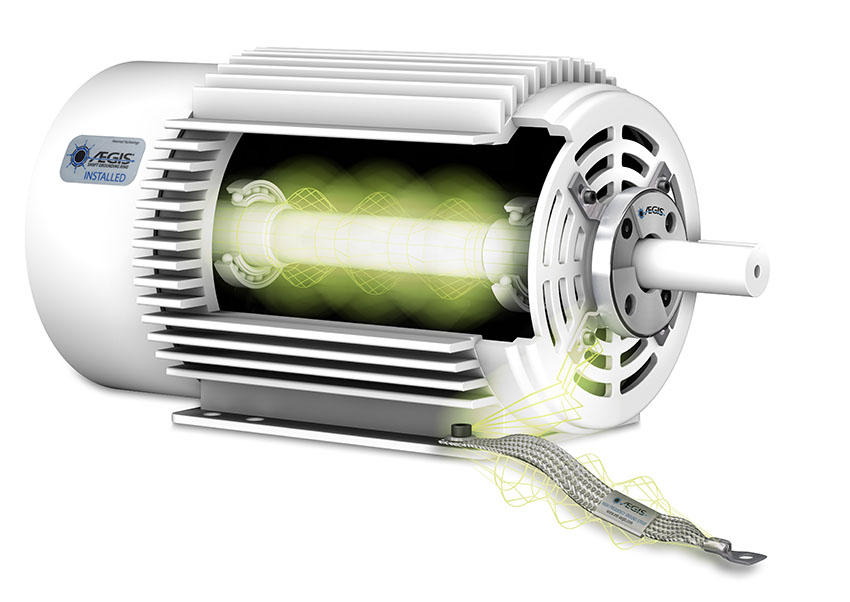

For over 30 years, Electro Static Technology (EST) has been a world leader in protection against the damage done by static and other unwanted electrical effects. Their AEGIS® Shaft Grounding Rings protect inverter-fed electric motors and generators against premature bearing failure. With over 10 years in serial production, millions of electric and hybrid electric vehicles around the world trust AEGIS shaft grounding rings to protect motors from electrical bearing damage.

Electro Static Technology is a division of Illinois Tool Works (ITW), a Fortune 200 global multi-industrial manufacturing leader with revenues totaling $12.6 billion in 2020.

Easy Engineering: What are the main areas of activity of the company?

ELECTRO STATIC TECHNOLOGY: Electro Static Technology developed the AEGIS® Shaft Grounding Ring in response to the need for bearing protection in VFD-fed motors. Since then, our rings have been used across a myriad of industries to prevent the consequential downtime that results from motor bearing damage.

E.E: What’s the news for 2021 about new products?

ELECTRO STATIC TECHNOLOGY: Development of new designs of the AEGIS® Shaft Grounding Ring for the automotive industry.

E.E: What are the ranges of products?

ELECTRO STATIC TECHNOLOGY:

- Various designs of AEGIS® Shaft Grounding Rings for every size of motor working in every type of application;

- Measurement equipment like the AEGIS® Tester, a digital oscilloscope for to measure shaft voltage on site;

- Our sales team provides 360° support around our rings including pre-purchase education, on-site voltage testing, and installation training.

E.E: At what stage is the market where you are currently active?

ELECTRO STATIC TECHNOLOGY: We serve several growing markets such as HVAC, paper and processing, water treatment, renewable energy, railway, and marine applications. New government directives (energy saving) across the world have driven our involvement in the automotive industry as the use of electric and hybrid electric vehicles is growing world-wide.

E.E: What can you tell us about market trends?

ELECTRO STATIC TECHNOLOGY: We are seeing greater adoption of our rings across several industries. Motor manufacturers are standardizing AEGIS® rings by offering them as a factory install option. Motor users have increased use of our rings due to the pressure to meet production timelines and prevent unplanned downtime. By protecting bearings in VFD-fed motors they are able to keep their operations running without unnecessary interruptions.

E.E: What are the most innovative products marketed?

ELECTRO STATIC TECHNOLOGY: Our AEGIS® Shaft Grounding Rings can be customized for any motor or application. Over the years we have regularly partnered with OEMs to build tailored solutions that work for them.

E.E: What estimations do you have for 2021?

ELECTRO STATIC TECHNOLOGY: Because of the value of our rings to both motor manufacturers and motor users, we experience growth during 2020. We expect that trend to continue and to see significant growth during the foreseeable future. To keep up with this demand we are expanding our staff everywhere from manufacturing to our global sales team.