Elesa+Ganter is a worldwide sales joint venture (present in more than 70 countries) between two manufacturers, Elesa and Ganter, that offers the widest product range of highly reliable standard parts destined for the mechanical industry for the construction of machines and equipment with currently more than 80,000 product codes.

Elesa S.p.A. (founded in 1941) has its headquarters in Monza, Milan (Italy), concentrating on designing and manufacturing standard parts in high-quality engineering plastics.

Otto Ganter GmbH & Co. KG (founded in 1894) with its headquarters in Furtwangen, Germany, is concentrating on the production of metal components.

Easy Engineering: What are the main areas of activity of the company?

ELESA+GANTER: Elesa+Ganter standard elements are designed to meet the needs of applications in several industrial sectors: packaging industries, machine tools, lighting and fitness equipment, equipment for outdoor environments, urban and public fittings. Some components are even used in environments subject to severe regulations requiring particular materials and features such as food processing, chemical and pharmaceutical industries.

E.E: What’s the news for 2021 about new products?

ELESA+GANTER: Elesa+Ganter headquarters are in a steady process of research and development – with respect to new products and material used. Examples are:

SAN Line components which offer protection against bacteria and fungi spreading. These components are destined for medical and hospital equipment, rehab and disability aids. This line offers two solutions: standard components in technopolymer with silver ion additives and metal standard parts with a powder coating based on zinc molybdate

Visually Detectable & Metal Detectable Lines are especially developed for the food and pharmaceutical industry. The technopolymer used for both lines is suitable for contact with food (FDA CFR.21 and EU 10/2011). The compliance with FDA regulations of the production materials allows in addition a high level of prevention against the risk of contamination of the food. The characteristics of both lines contribute to increasing the levels of safety in food production processes in full compliance with international regulations. VD products are made of technopolymer in „Signal Blue” which is easy to detect within the production process, while MD components are made of technopolymer in „Green Blue” with special additives that allow the detection of cubic particles of 5 mm by means of a metal detector.

A product group especially developed for applications where hygiene is top priority is the Hygienic Design product group. Standard parts in this group combine high surface quality, freedom from dead spaces, non-scooped outer surfaces, and sealed bolting areas. A sealing concept based on FEM calculations ensures reliable contact pressure after installation.

Hygienic Design also means that the time and material needed for regular cleaning is significantly reduced – which also noticeably lowers operating costs. By the way our Hygienic Design standard parts meet the high requirements of EHEDG, 3-A sanitary standards and DGUV.

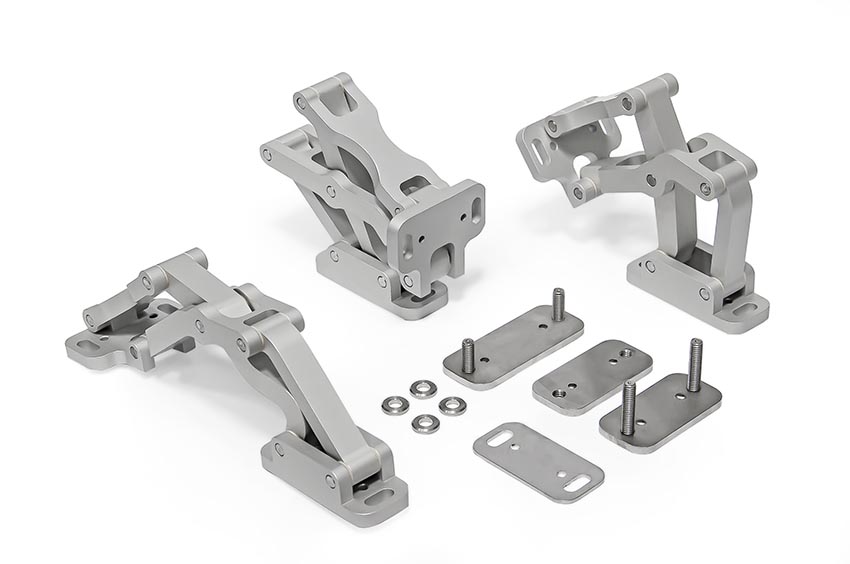

Another innovation in the Elesa+Ganter product portfolio are the multiple-joint hinges. The big advantage of this hinges is that they are installed inside the doors, flaps and hatches in order to save space and ensure protection against vandalism. Furthermore, multiple-joint hinges leave housing exteriors free of attachments that do not match the design or that should be avoided entirely in the interests of fast and easy cleaning.

Brand new in our catalogue are the quick release couplings. Basically, quick release couplings are frequently used in events to rapidly set up and take down stage equipment. This advantage is now leveraged for industrial applications and the proven functional principle was adapted to this context. For repeated machine set ups or assemblies that require the inconvenient use of a screwdriver, quick release couplings can be used on fixtures or production lines to efficiently mount guide rails, covers or additional devices.

E.E: What are the ranges of products?

ELESA+GANTER: Our catalogue offers everything from indexing elements, handwheels, knobs and levers to control elements, rotary controls, machine elements and everything in-between.

The complete range is available on the website, where engineers and designers can also find and download 2D and 3D CAD models.

In the range we also have High Performing Items with special features to meet specific needs and applications. Examples for those are ATEX or ESD components as well as standard parts in stainless steel.

Among this line, we mention the SOFT-TOUCH Line which features a soft and slip-proof surface to ensure a safer and more stable ergonomic grip even under unfavorable conditions of use. CLEAN Line products designed for medical and hospital equipment are in RAL 9002 white colour, which allows the prompt identification of any dust or dirt traces, making cleaning operations easier.

If a customer is missing something, we even have the option to customize quite some products in our portfolio to the specific needs – depending on the product and quantity needed.

E.E: At what stage is the market where you are currently active?

ELESA+GANTER: This year we are experiencing a growth in a lot of sectors – e.g. in the production of machinery and equipment as well as the building sector. This is actually a worldwide trend.

E.E: What can you tell us about market trends?

ELESA+GANTER: Surely the most sought-after market trend by Elesa+Ganter headquarters is to offer products that offer greater safety for the operator. In fact, the range includes products that meet safety requirements and regulations, but also products designed meticulously to guarantee total safety, such as handles without protrusions, safety fold-away handles, compact and ergonomic shapes.

In recent years, also driven by the global situation we are all facing, Elesa+Ganter has further expanded its lines which offer sanitization and greater easy cleaning, such as the already mentioned SAN, CLEAN and Hygienic Design. Especially in these months, such products are strongly requested.

E.E: What are the most innovative products marketed?

ELESA+GANTER: For standard parts there is a trend towards more automated products to have more safety in production processes as well.

GN 817.6 stainless-steel indexing plungers with a sensor for positioning monitoring. They allow an electronic monitoring of the plunger pin state. For this, a magnet is integrated into the plunger pin that switches the sensor upon engaging after approx. 2/3 of the locking distance. The sensor electronics then outputs a high signal, e.g. to a machine control, and additionally indicates this switch state with a LED on the sensor.

Another example are the electronic position indicators (DD51-E-RF and DD52R-E-RF) and the magnetic measuring system, MPI-R10-RF, that transfer data via radio frequency. So, no cables are needed. They are suitable wherever frequent format changes are required. With this system up to 36 position indicators/magnetic measuring systems can be combined. They are networked to the control unit UC-RF via radio frequency which is connected to the PLC. This does not allow the beginning of the production circle as long as not all components are in the correct target position. So, production issues are reduced to a minimum.

Another innovation in our catalogue is GN 314 stainless-steel locking pins that are lockable. With the L-handle and key they are used for quick fixing, connecting and locking of various jogs and fixture systems without any needs for tools.

Last but not least the new bridge handles EBR-SWB and EBR-SWM with electrical switch which enable remote electrical operation of safety interlocking and multiple latching system while one-handedly opening the related door or safety panel.

E.E: What estimations do you have for 2021?

ELESA+GANTER: 2021 is almost done and we expect the positive trend to continue also for 2022.