Embotech is a leading developer of cutting-edge decision-making software. Their embeddable software empowers autonomous systems to make decisions by solving complex optimization problems in milliseconds, bringing significant improvements in safety, productivity and energy efficiency. Embotech’s numerical core software tool FORCESPRO is based on physical models, using a deterministic mathematical approach with numerical optimization. The company works with businesses in automotive, industrial automation and aerospace as well as the academic community.

Embotech, short for Embedded optimization technologies was founded in 2013 as a spin-off from the ETH Zurich. Today, the company is a growing tech SME in the heart of Europe with an international team and more than 50 customers around the globe.

Easy Engineering: What are the main areas of activity of the company?

EMBOTECH: In Automotive, Embotech develops motion planning technology for ADAS systems and level 3 to 5 autonomous driving. Based on FORCESPRO, Embotech has developed its own Motion Planning software, the PRODRIVER, which allows various vehicle types to drive fully autonomously. In addition, they offer high-end Energy Management for hybrid and electric vehicles.

In Industrial Automation, Embotech enables robots, wind energy systems and other industrial machines to be more efficient, productive and safe, responding to the current challenges of industrial automation.

In Aerospace, Embotech advances guidance and control solutions for aerospace systems and drones. Their key technology enables On-board and Real-Time trajectory generation.

E.E: What are Embotech’s latest product innovations?

EMBOTECH: This year, we introduced three new products, all of them based on our core technology FORCESPRO. As mentioned above, we merged our previous module for Autonomous Driving into the PRODRIVER, a software product family for driving various vehicle types in a multitude of use cases. While the construct of autonomous driving for passenger cars still seems a bit like tomorrow’s reality, autonomous driving for special vehicle or in sectors like logistics actually happens today. Thus, our motion planning solution PRODRIVER is now being used in gated areas.

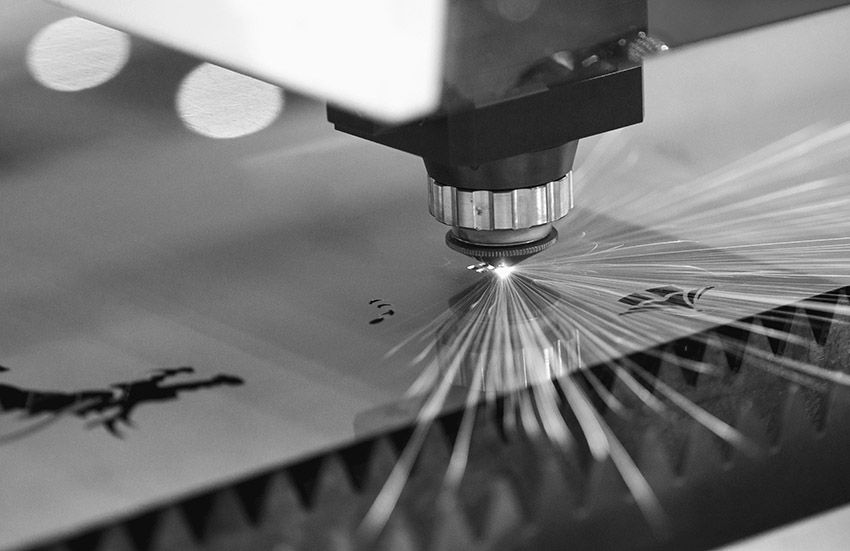

Our second innovation this year is PROBOT, a tailored motion planning software for robots and industrial machines. This product has been launched recently in cooperation with an leading company in the sheet metal processing business.

And last but not least, we have introduced PROTECT, our ISO26262 trajectory validator and as such a safety component of PRODRIVER.

E.E: What is Embotech’s strategy 2020+?

EMBOTECH: Embotech’s mission is to empower autonomous systems to make better decisions. This mission unfolds into different strategic directions for our 3 main business areas.

In the Automotive business unit, which includes all types of ground vehicles, the strategy is threefold: a) to merge our two previous modules for parking and highspeed driving into one product the PRODRIVER, working seamlessly in all applications, b) to work on functional safety so that our product can be accepted in applications with stringent safety standards in the medium term and c) to focus on AD applications which are going to market in the short term, such as autonomous driving for parking and logistics, mining and other geo-fenced, private road applications.

In the Industrial Automation unit, we plan to extend the capabilities of the technology on industrial machines like laser cutting and bending and bring it to serial production within the next few months.

Apart from that, we are building a robot motion planning software stack and look for the most suitable partners in order to commercialise it.

In the Aerospace segment, which includes all types of aerial vehicles with focus on rockets, the strategy is to build a technology platform for and around Guidance and Control algorithms in collaboration with ESA. In parallel, we start working with industrial players in consortia in order to make the first moves towards commercialization of our products in the nascent space market.

E.E: This year being tainted with Covid-19, what were your priorities for Embotech in 2020?

EMBOTECH: In the aftermath of Covid-19, the immediate priority has been to secure liquidity and keep the employees motivated and well informed about what is going on in the company, since most are still or again working from home. For several months in the beginning of the year, the focus has been on core product development and subsequently, as things were opening up again, on building up the pipeline of customer projects again. We have been fortunate to have more than enough customer projects throughout the Covid-19 crisis thus far, however in B2B businesses like ours the pipeline takes a long time and effort to fill, and the traditional channels such as conferences and trade shows have not been available and won’t be in the near future. Eventually, in the second half of 2020 Embotech has been focusing on software maturity and functional safety on the one hand, and on the other on enhancing our IT infrastructure to be more resilient and robust, including more sophisticated cybersecurity preparedness.