EMSYST was established in 1995 with the aim of supplying the market with quality products with high added value in the field of automation and measurement. The founder of the company worked for a long time in the field of measuring technology and transferred the acquired knowledge and experience to the newly established company. The result is original solutions for single-purpose machines and the development of EMSYST’s own products – force sensors. Their sensors have gradually become popular in the markets of Central Europe for their quality, affordability, customer support in the selection and their installation.

Easy Engineering: What are the main areas of activity of the company?

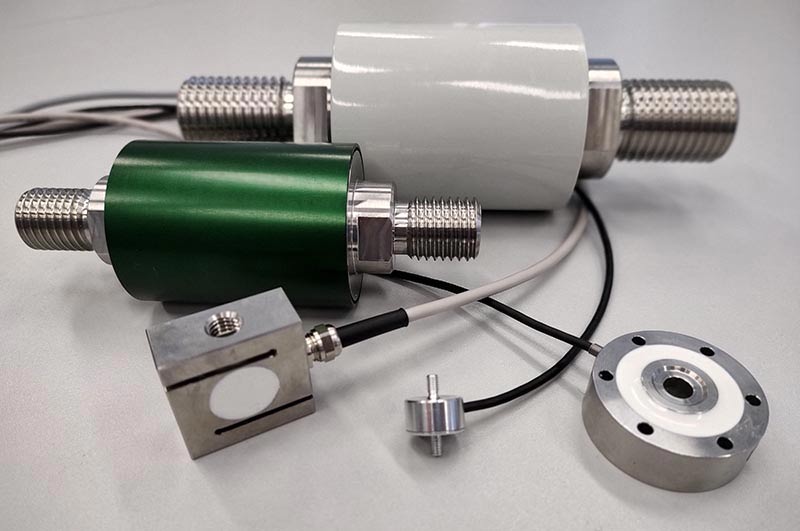

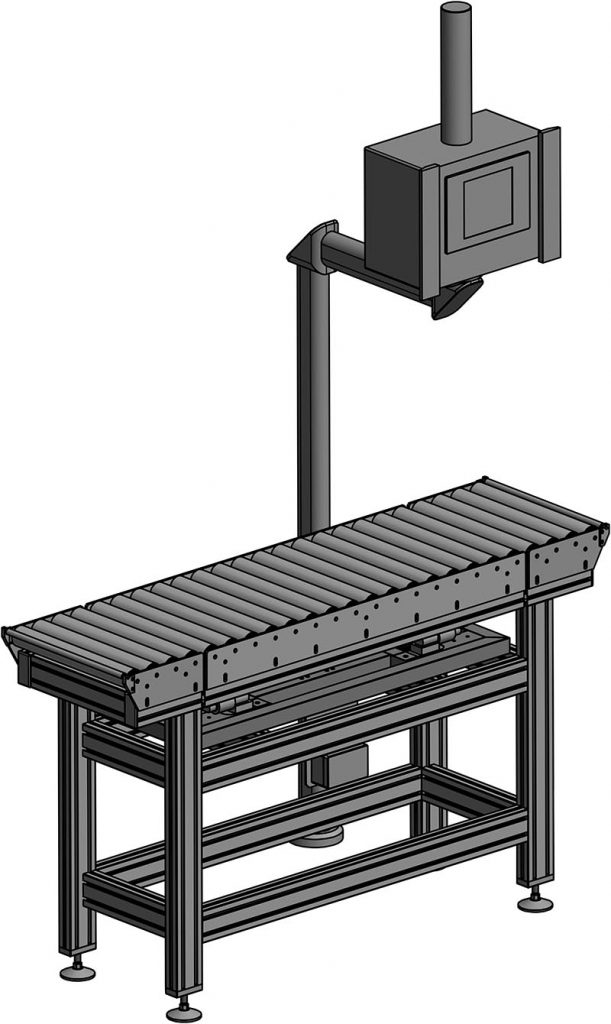

EMSYST: The main activities of our company include the development and production of strain gauge force sensors and electronic units for processing output signals. However, not all applications can be covered by our standard sensor portfolio, which is why we also develop custom sensors. Each sensor can be characterized by parameters such as shape, mounting method, maximum force range, accuracy, form of the output signal and the necessary protection against external influence like weather. We can deliver a functional prototype with an international calibration certificate within a few months of ordering. We also deal with the application of force sensors and automation. An example is the construction of checkweighers for the rubber industry, which are part of production lines in many countries around the world.

E.E: What’s the news about new products?

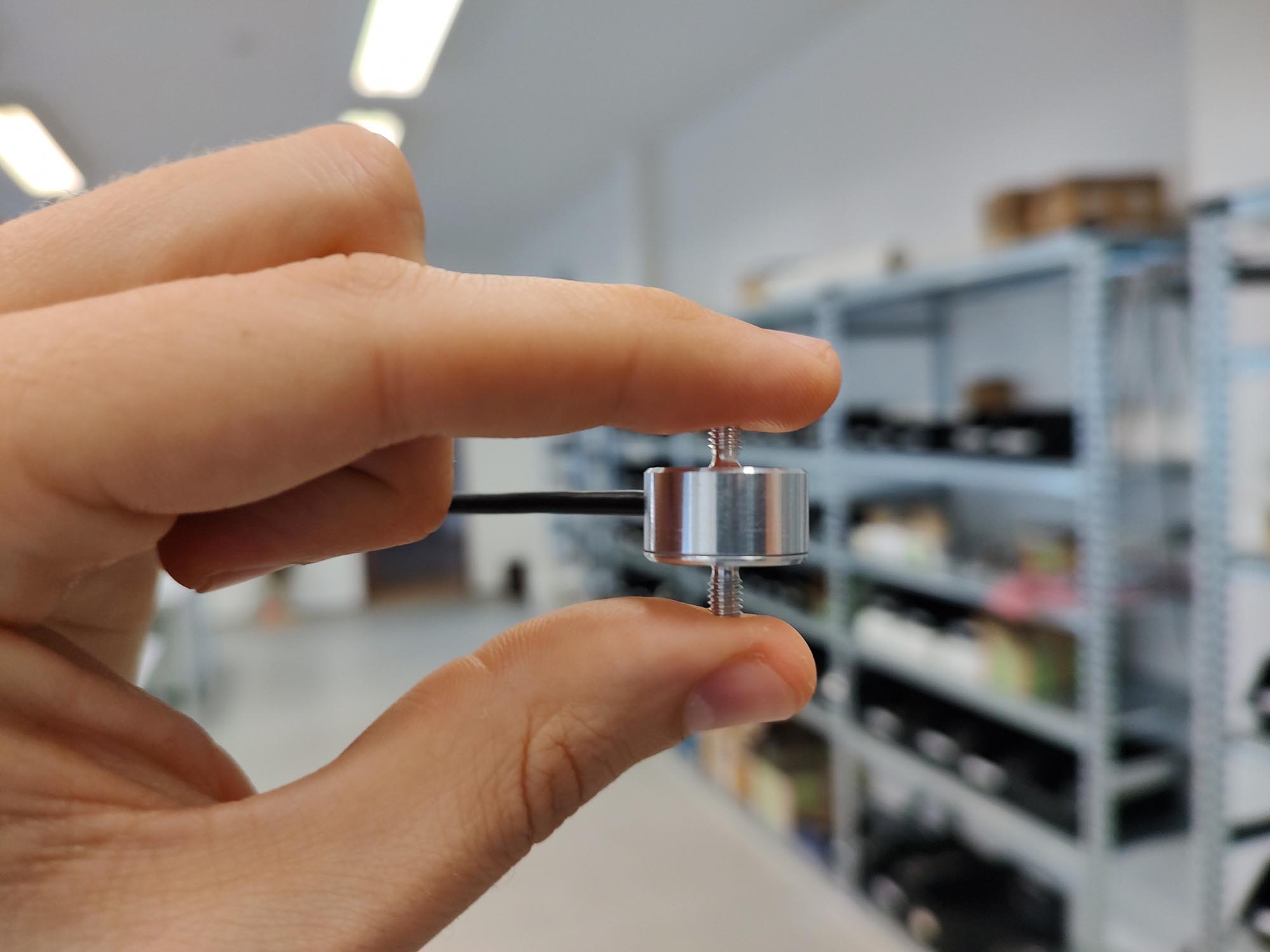

EMSYST: We have introduced a new series of sensors with a built-in electronic unit. The standard sensor provides an output signal in the range of 10 – 20 mV, which is usually too weak for direct processing. For this reason, an electronic unit is offered for the sensors, which is usually in the form of an external box mounted on a DIN rail. The electronic unit supplies the sensor with supply voltage and amplifies the output signal to an industry standard value of 0 – 10 V or 4 – 20 mA, which is easier to process. We built-in this electronic unit into the body of the sensor. All you have to do is connect a standard 5 V or 24 V supply voltage and connect the output signal directly to the PLC or measuring card. Our customers have started to prefer this solution for its simplicity.

E.E: What are the ranges of products?

EMSYST: In the field of force sensors, our company offers cost-effective membrane sensors with a measuring range from 50 N to 500 kN. In addition, other types are available with higher accuracy and a range of up to 3000 kN. Our sensors are applied in various industries in factories and outdoors in extreme conditions from frozen Siberia to the desert in the Middle East, from measuring the force of a push of a button to weighing full railway wagons.

E.E: At what stage is the market where you are currently active?

EMSYST: Most force sensors manufactured in the world are used for scale construction, the rest in machine construction and for special measurements. In the second area, smaller companies in particular are active, which can respond more flexibly to customer requirements. They produce smaller series of sensors, or sensors developed exactly according to customer requirements. EMSYST also belongs to this group.

E.E: What can you tell us about market trends?

EMSYST: A clear trend in the field of force sensors is digitization and personalization. The analog output signal is more often replaced by a digital bus. The calibration process, which is a costly affair for sensors, is also automated. By personalization we mean mainly the adaptation of the product to the customer’s needs. On the other hand, sensors with analog output cannot be expected to disappear from the market. Sensors with an accuracy of 0.2 – 1% are usually sufficient for machine monitoring. In this case, a simple sensor with an analog output is the best choice, not only in terms of input costs but also maintenance. This is especially true at the present time, in a period of rising material and energy costs, and shortages of electrical components.

E.E: What are the most innovative products marketed?

EMSYST: We consider sensors with the IO-Link bus to be one of the most innovative products in the field of force sensors. We think that this communication network standard is the near future of sensors and every manufacturer should be prepared for it to become a standard in our segment. Our company is therefore actively preparing to launch a series of force sensor with IO-Link support.

E.E: What estimations do you have for 2022?

EMSYST: We assume that with the end of the pandemic approaching, production will restart and thus the demand for sensors will increase again. Major manufacturers will continue to set the direction in which automation and measurement technology will take. Our company plans to strengthen its position in the markets in Europe in which it operates. We also plan to launch some new products in the field of digitization of our products. We hope that the year 2022 will bring more interesting projects and technical problems, with which we will be able to help our customers.