Engilico (Belgium) provides innovative seal inspection technologies to inspect, optimize and monitor the sealing process of flexible and rigid packaging. These technologies enable customers to realize better packaging quality, higher packaging productivity and end-of-line automation. With hundreds of installations worldwide, Engilico’s technology warrants package integrity and shelf life, reduces customer complaints and therefore improves the brand image of leading international companies within the global food, pet care and other industries where sealing integrity is of utmost importance.

Interview with Renaat Van Cauter, Marketing Director at Engilico.

Easy Engineering: What are the main areas of activity of the company?

Renaat Van Cauter: Contamination in the sealing area causes important issues for food companies as it may lead to leakage and consequently reduced shelf life, health issues and even expensive recalls with potential brand damage. As such automatic detection of contaminated seals is important for both food safety and production automation in packaging. Engilico offers innovative in-line solutions for this challenge, both for flexible and rigid, plastic packages.

E.E: What’s the news for 2021 about new products?

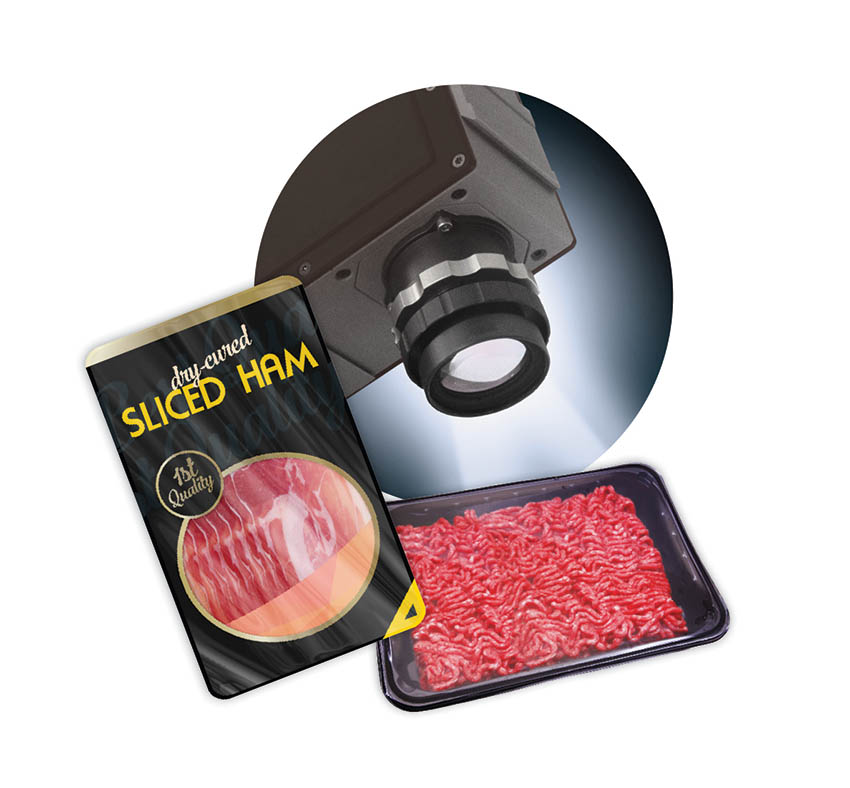

R.V.C: Engilico™, pioneer in non-destructive in-line seal inspection for flexible packaging, introduces a new inspection solution for rigid plastic packages, such as trays, pots, thermoformed packages. The HyperScope™ inspection solution uses hyperspectral imaging (HSI) technology to detect contamination in the seal of trays with a much higher contrast than standard vision cameras. Even with printed plastic foils, when contamination is not visible for traditional vision-based systems, seal contamination can be detected by a hyperspectral camera.

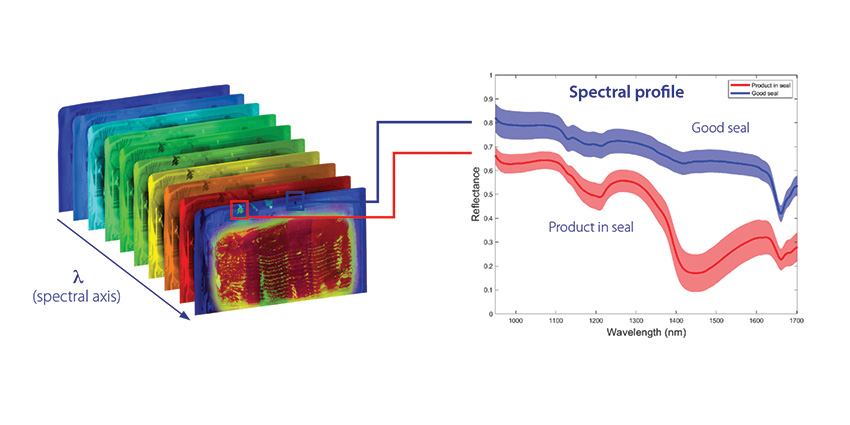

Product in seal often causes issues for standard vision systems, as there might be not enough contrast between the plastic film and the contamination. In case of printed packaging, often used in more luxury packaging, the contamination can even not be seen. A traditional vision camera provides a single image with spectral information from the three primary colors (RGB). Hyperspectral camera technology results in hundreds of images, each with information of a specific wavelength range, including infrared wavelengths. For the detection of contamination in the seal, the relevant wavelengths are merely situated in the (near)-infrared region.

As different materials react uniquely to infrared light, they can be reliably detected based on their specific transmission, reflection and absorption properties. Since hyperspectral imaging delivers the spectrum for each pixel in the image, it provides information about the chemical composition of the measured sealing area. As such hyperspectral imaging allows to distinguish with high contrast undesired materials such as meat, fat, oil from the plastic film, even if it is printed. Also because infrared light penetrates the top film, contamination can be detected through printed top film.

Typical applications are in-line seal inspection of trays or pots with meat, fish cheese and vegetables. Watch a video how HyperScope works!

The hyperspectral 3D spectral image map is built from hundreds of images in different wavelength bands. Every pixel is analyzed individually and differences in materials or composition can be detected, even through printed film. A contaminated seal has as a different spectral profile than a clean seal.

E.E: What are the ranges of products?

R.V.C: Engilico offers seal inspection solutions for the most common types of food packages such as pillow bags, pouches, horizontal flow wraps, trays, pots and other thermoforms.

As explained in the previous answer HyperScope™ provides in-line seal inspection for rigid containers with a plastic transparent or opaque top foil.

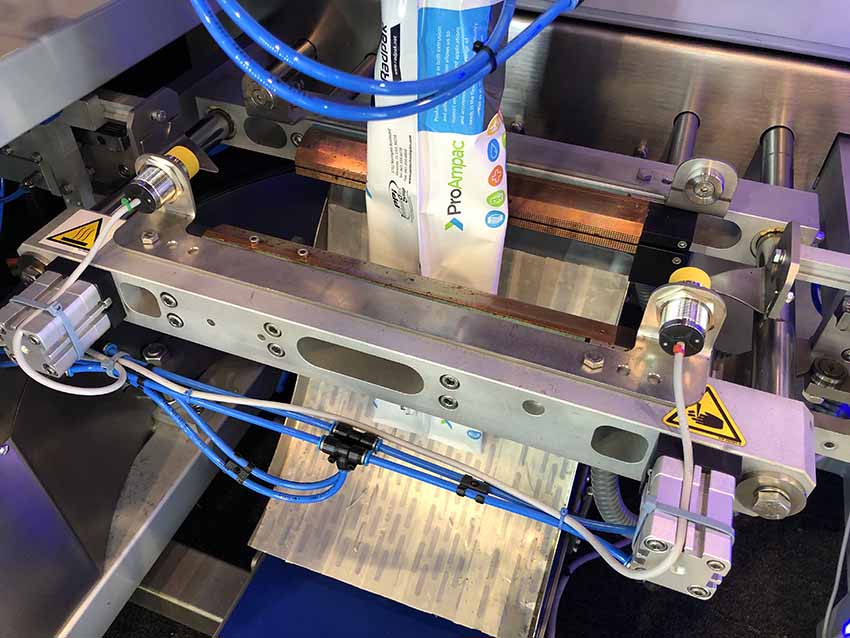

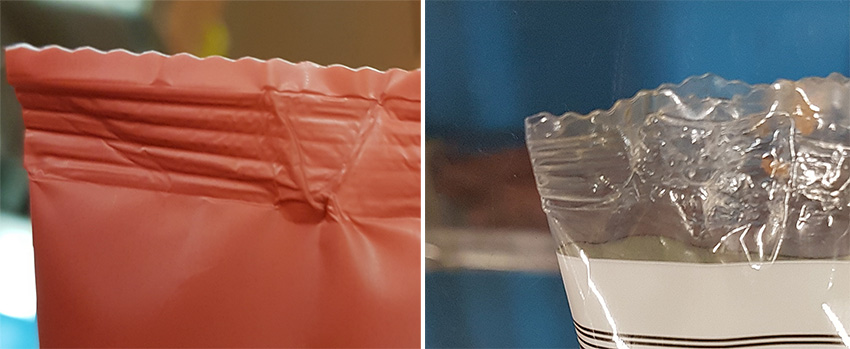

For seal quality control of flexible packages Engilico presents its patented SealScope™ an easy to integrate and non-destructive in-line seal inspection and process monitoring technology. Via sensors mounted on the sealing jaws, SealScope™ detects product in seal, wrinkles and tapered seals. As every single package is inspected, SealScope™ also issues early warnings for process drift, enabling preventive machine maintenance.

Watch a video on how SealScope works

E.E: At what stage is the market where you are currently active?

R.V.C: Engilico celebrates this year its tenth anniversary. Its unique solution SealScope is retrofitted to more than 180 packaging systems worldwide at leading companies in mainly food and pet care. The potential market is huge as nearly all food and ingredients are packaged -often under modified atmospheric conditions to extend package content integrity- and demands for excellent product quality and productivity are high. As SealScope is retrofitted to the sealing bars of existing or new machines, and independent of the machine brand, it addresses an immense, worldwide market. Also, for HyperScope, our solution for rigid packages, the market potential is huge. Trays, pots or containers with plastic top sealing are used by many food producers and even often complementary to their flexible packaging portfolio. As well as with flexible packaging, seal inspection to prevent leaking packages is equally important for thermoformed packages.

E.E: What can you tell us about market trends?

R.V.C: The trends for the food packaging market are realizing a high, persistent product quality, increasing or optimizing the packaging productivity and automating the complete food packaging production line.

Product quality is a key element to prevent expensive call-backs, to preserve brand quality and to maintain competitive advantage. In-line, 100% seal inspection improves outgoing product quality as every package is inspected, it is prone to human quality control errors and works at high packaging speeds.

Also, to increase the packaging productivity, in-line seal inspection is importance as the production manager can determine the optimal machine speed where production output and package quality are maximized. As every package is checked, one can see deviation trends in the packaging process, enabling preventive maintenance and instant machine fine-tuning. Additionally, rejection of open packages will reduce downstream contamination and standstills.

Finally, by automating the seal inspection process, manual labor can be reduced and end-of-line automation realized.

E.E: What are the most innovative products marketed?

R.V.C: Important elements for innovative products are that they offer a solution to an existing challenge to finally result in clear advantages for the manufacturer. The solution needs to be robust even at high production speeds, non-destructive to prevent waste, and fully integrated in the packaging line.

Both SealScope and HyperScope fulfill the criteria for innovative technologies.

While SealScope uses more traditional sensors, it makes use of advanced inspection algorithms to determine good and defective seals.

HyperScope uses advanced hyperspectral imaging, a relatively new technology that analyses images in a broader wavelength range than traditional cameras and therefor even can see through opaque top films. Of course there are other innovative food inspection solutions such as X-rays, advanced vision cameras, but these do not offer the same capabilities for seal inspection and are therefore often complementary to Engilico’s solutions as they serve other inspection goals.

E.E: What estimations do you have for 2021?

R.V.C: As the world population and production is ever growing, the food packaging market will continue to further invest in product quality, production speed, competitiveness, and brand image. With Covid19 slowing down the investments in the global (food) industry in 2019 and 2020, there will be an important catch-up in 2021 and beyond. Therefor the future is looking positive.