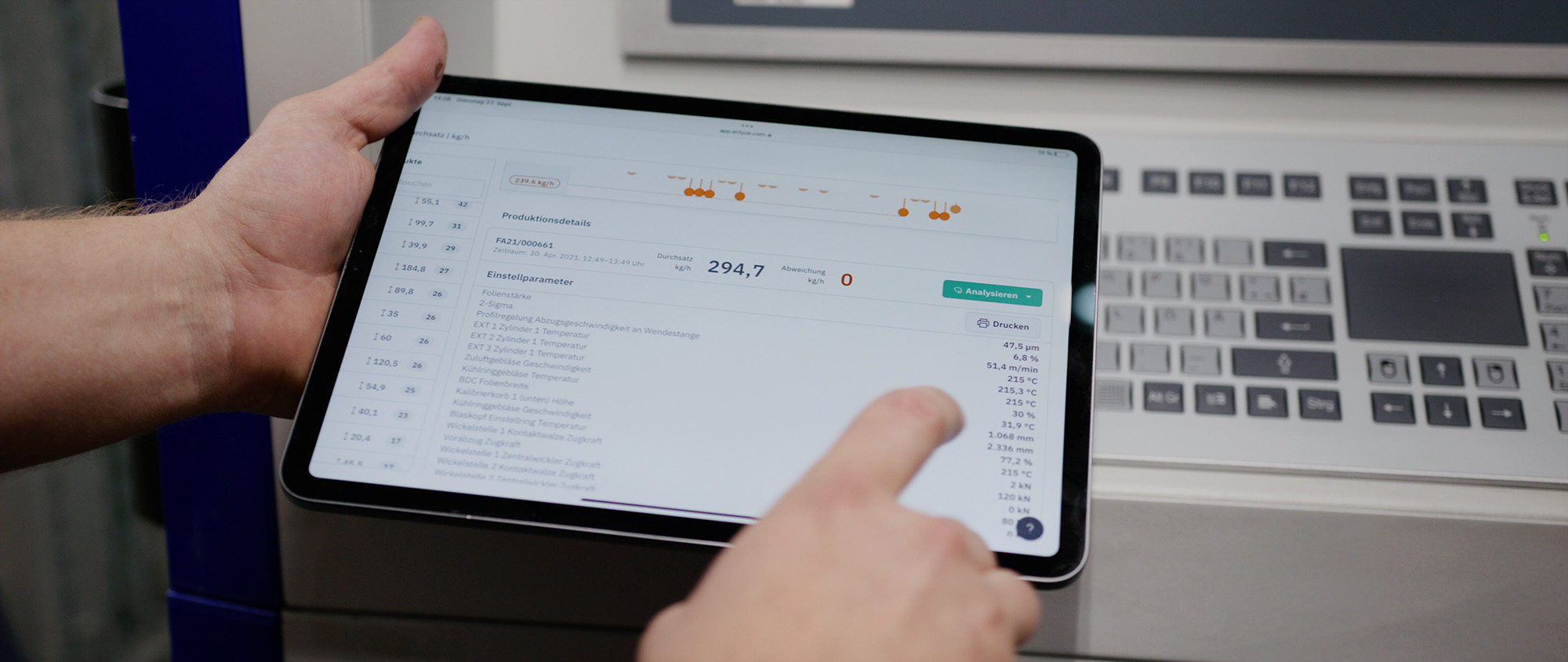

ENLYZE offers a hard- and software solution that provides access to machine data in heterogeneous manufacturing environments via direct connection to PLCs or Sensors. In the app, ENLYZE enables data-driven productivity management by capturing the manufactured reality: assessing the productivity based on machine data instead of manual worker feedback resulting in highly accurate productivity KPIs.

Utilizing the machine data further, data-driven improvement actions can then be derived and their progress objectively measured and compared. Decisions based on gut feeling are replaced by data-driven decisions.

Interview with Henning Wilms, Co-Founder & CEO of ENLYZE.

Easy Engineering: What are the main areas of activity of the company?

Henning Wilms: Our data platform is tailored for (semi-)continuous production companies with around 80% of our customers related to the plastics industry in Europe. That being said, our connector portfolio covers 99% of industry standard PLCs, and the data can be integrated everywhere, not only in our out-of-the-box analytics platform “ENLYZE Shopfloor BI”. We offer custom use cases with full access to the machine data in standard tools like Grafana, Power BI, via a Python SDKs and more. By integrating into these tools, our customers are fully empowered to continue developing their dashboards and analysis without having to be software engineers.

E.E: What’s the news about new products?

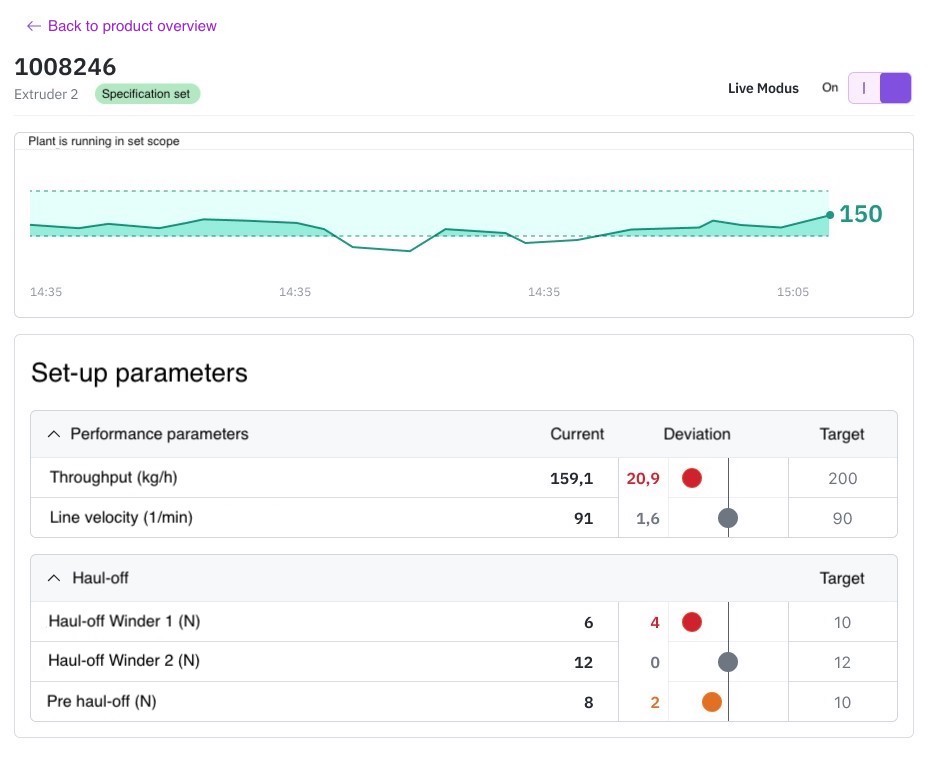

H.W: Currently, we are working on adding common, industry-wide use cases to our “Shopfloor BI”, such as the detection of downtimes reasons. This complements our focus on the use cases clients have been asking us for and we’ve been building the past year. Our latest addition was our operator co-pilot, which is a tool that shows machine operators the optimal set-up for the machine parameters, based on actual historical process data of the same product on the same machine.

E.E: What are the ranges of products?

H.W: Our core product is getting access to machine data by connecting to machine PLCs. Once connected, we perform some data engineering steps to ensure the validity and reliability of the captured data.

After this, clients have two possibilities: They can use our out-of-the-box data analytics platform “ENLYZE Shopfloor BI” with common use cases included, like downtime detection, process data analytics, productivity calculation etc. If clients need more in-depth data analysis, they can build fully custom dashboards using one of our many integrations into tools like Grafana or Power BI, or build fully custom apps with Python SDKs.

E.E: At what stage is the market where you are currently active?

H.W: Our market is mainly located in the plastics industry in Europe, which is a very traditional market, but is facing high demand for innovation due to the upcoming climate change and raw materials shortage challenges. We experience a growing demand for data analytics and process optimization all over the industry, especially with regulatory requirements for using recycling material tightening and energy prices soaring.

E.E: What can you tell us about market trends?

H.W: The current trend in our industry, naturally due to climate change, is in finding more sustainable ways of producing. Recycled materials is a big trend, as well as following stricter government and industry regulations.

These needs require producers to gain more insights into their production, e.g. to show clients the carbon footprint of their products. Data collection will play a huge role in this because it ensures correct data for these reports.

E.E: What are the most innovative products marketed?

H.W: Many of our clients have a wide range of recycled plastics in their portfolio and are working hard to make these products as competitive as standard, low-cost, non-recycled plastics. We believe this to be one of the leading innovations in our industry, as it will show a way for plastics to stay relevant and compatible with climate change regulations, especially due to still high demand both from private and industry clients.

E.E: What estimations do you have for 2023?

H.W: For us, 2023 will be the year that’s all about digitization. Many European producers are understanding the need for data, not only to stay competitive, but to also follow regulations that are increasing every year. In these times, solutions that provide real value for the price will be highly sought after, and we trust in our expertise to not only give production companies access to data, but also the necessary tools and processes to use them in a profitable way.