From the early 80’s Eurostat has been amongst the earliest European pioneers for ESD -Electro Static Discharge- protection. With nearly 40 years of manufacturing experience, Eurostat has based its growth model on being an integrated manufacturer for most of the ESD products sold.

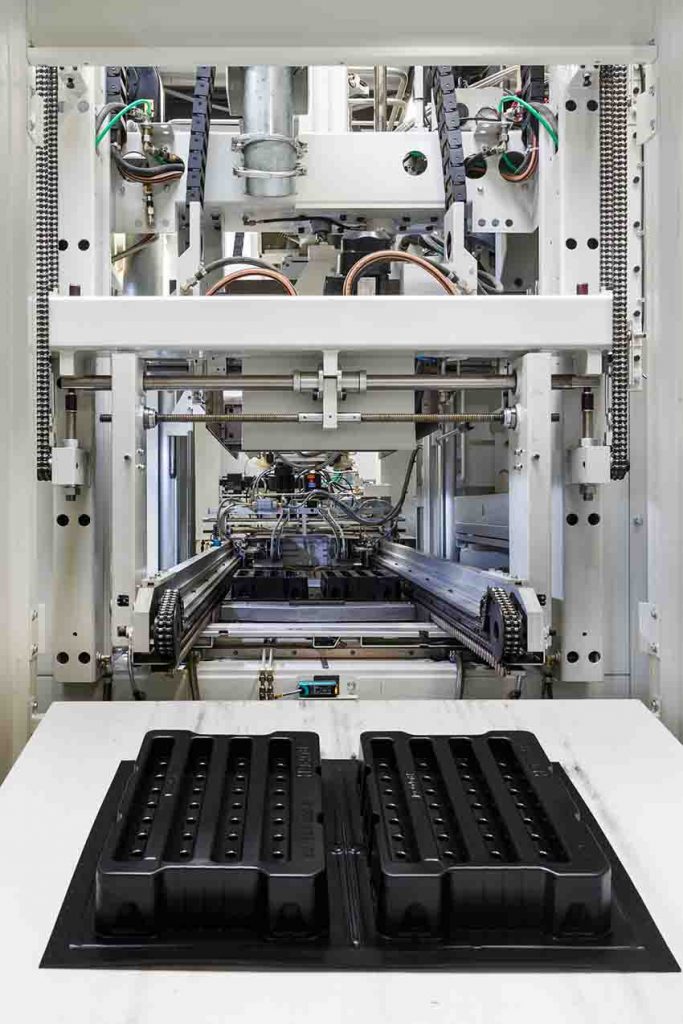

This is how Eurostat has acquired a unique and recognized expertise, with a vertically integrated manufacturing facility, covering raw material extrusion, vacuum forming, flexible packaging manufacturing, and all the necessary secondary operations needed for bespoke packaging solutions.

The company also provides a one stop solution to all ESD needs throughout global partnerships.

Interview with Michèle AMIOT-MAITRE, Marketing Officer at Eurostat Group.

Easy Engineering: What are the main areas of activity of the company?

Michèle AMIOT-MAITRE: Thanks to a thorough knowledge and experience in solid state physics and electronics, Eurostat’s aim is to offer some innovative solutions for the protection of devices sensitive to ESD hazards and particle contamination, during production and shipment processes.

Over the year, Eurostat has acquired specific industrial know-how resulting in some original patent pending industrial processes. Thanks to our experience in thermoplastic extrusions, Eurostat has engineered some proprietary compounds, such as E-STAT® or Nano-STAT®, to offer appropriate and competitive solutions for the protection against ESD hazards.

Eurostat are involved in partnerships to propose innovative logistic solutions meeting emerging and future customer needs.

E.E: What’s the news about new products?

M.A.M: This year at Fachpack in Nuremberg/Germany (27-29 sept.) and at Scanpack at Goteborg/Sweden (4-7 oct.), we release our new solution Track and Tray: a real-time tracking of vacuum formed trays used in automated production lines for ESD sensitive products.

E.E: What are the ranges of products?

M.A.M: Eurostat Group offers a large selection of products to answer all needs of our customers regarding ESD Protection. Rigid Packaging, Flexible Packaging, Instrumentation & Ionization, EPA Equipment and Personal Equipment.

E.E: At what stage is the market where you are currently active?

M.A.M: Eurostat has been a producer of its own raw material. This allows us to be the owner of registered innovative materials, embodying our know-how. These materials are the result of internal development and collaborations with research facilities and partnerships world-wide. These registered materials represent an advancement for the market of protection against micro nuisances.

Eurostat’s vacuum formed trays cover all needs of our market place with dissipative, conductive and insulative materials. Dimensions up to 800 x 600 mm Thicknesses covering from 0.6 to 6 mm.

E.E: What can you tell us about market trends?

M.A.M: Sustainability is in the agenda of a lot of companies. Especially in the plastic industry. At Eurostat, we believe that recycling old ESD transport trays can contribute to the circular economy and reduce the global CO2 footprint of our industry. We are developing with our customers the recycling of all reusable plastics used in our Industry (PS, ABS, Pet, ABS/TPU, PE). With our production sites in Europe, we organize with minimum transportation, the circular loop.

E.E: What are the most innovative products marketed?

M.A.M: Our E-STAT® material. The only safe solution to ESD handling. Made of permanent static dissipative PS, adapted to clean environment, no heavy metal content, no particular emission due to the absence of carbon powder, E-STAT® offers the true ESD protection inside & outside EPA.