Easy Engineering: How was this year in terms of turnover?

Faber-Com: The global pandemic did impact heavily on the turnover over the first semester (especially due to the Italian lockdown between March and April). However, the positive results during the very first months of the year, as well as the important bounce back in the second semester of 2020 allowed Faber-Com to slightly increase its global yearly turnover also in this difficult year.

E.E: What new products / services have been launched this year?

Faber-Com: In recent years, Faber-Com has been regularly launching new electronic control devices as well as complete, integrated control solutions. In this sense, its 2020 wasn’t different, being marked by several new solutions manufactured by Faber-Com:

- The MAP3, a single axis joystick, available with PWM, voltage or CAN bus output, specifically designed for marine applications;

- The CPD, a brand new, programmable, proportional regulator for the control able to directly command a couple of proportional coils, starting from an analogue reference signal in the range 0.5V ÷ 2.5V ÷ 4.5V;

- The FIPR-C, a 2-axis, redundant inclination sensor with CAN bus output, suitable for safety applications (e.g. aerial platforms);

- The PCG, a multifunction proportional joystick handle with an integrated electronic card that can directly command a couple of PWM proportional solenoids.

E.E: What feedback did these product / service launches have?

Faber-Com: Although it is still difficult to make proper evaluations, all the new devices launched during 2020 did receive positive feedback.

In particular, the new range of single-axis marine joysticks aimed to satisfy an important need expressed by the market: having a reliable and programmable electronic manipulator resistant to high-salinity environments. Therefore, it is no surprise that the sales of this product rocketed right after its introduction.

Similarly, the CPD proportional PWM regulator has almost immediately caught up the attention of Faber-Com’s customer base. This electronic control card is fully programmable by the user thanks to a simple serial interface adapter and, thanks to its flexibility, can have countless different applications in the mobile hydraulic field.

E.E: What products / solutions have customers been looking for this year?

Faber-Com: Perhaps, the most important trend to be highlighted on the demand-side is the increasing need of integrated solutions.

Supplying a complete “package” often becomes the key to success and this proved to be even more important during 2020.

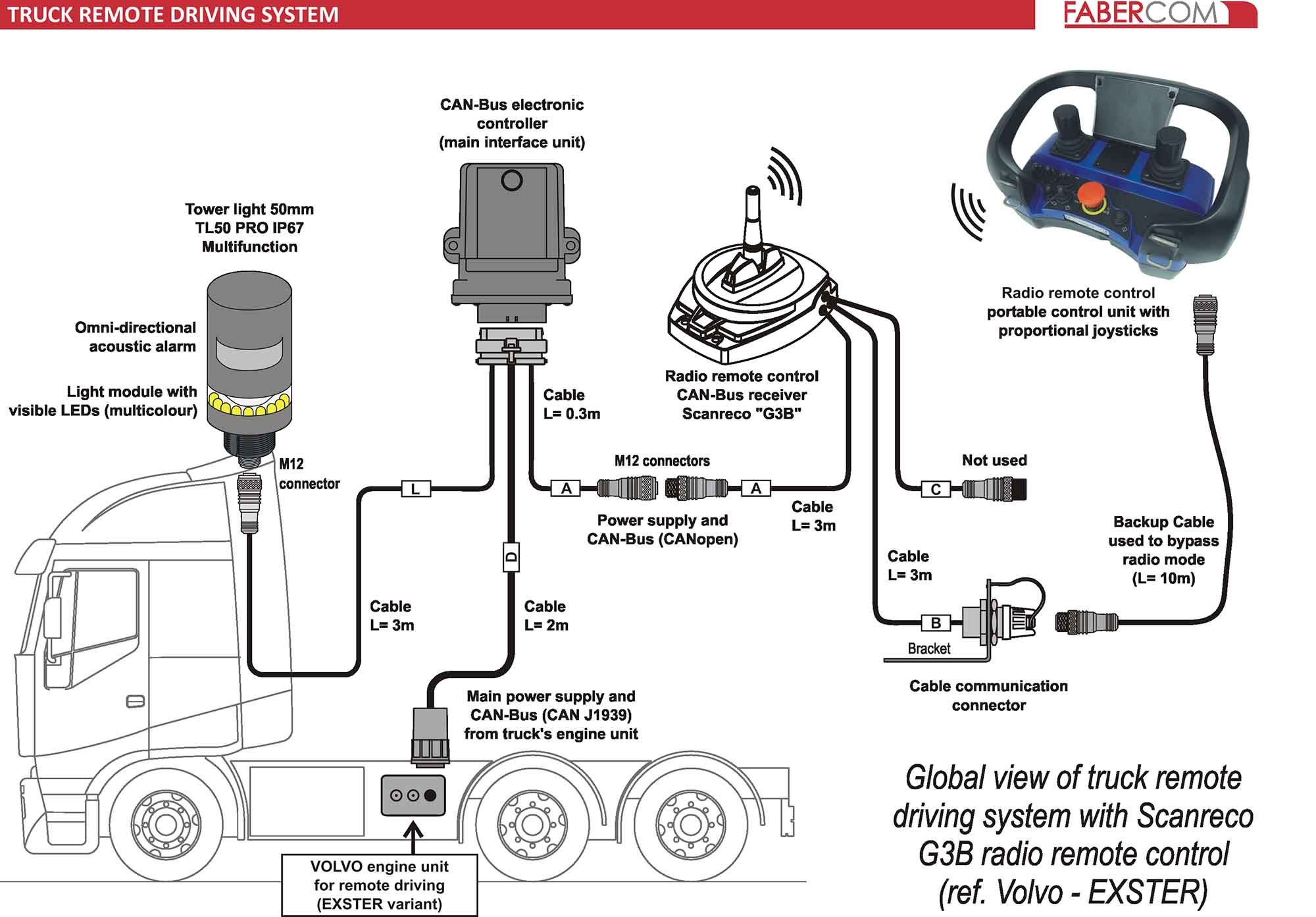

One example can be Faber-Com’s new radio remote truck driving kit, designed for trucks equipped with external steering interfaces (i.e. Volvo Exster, some Scania models, etc.). With these solutions, supplying all the requested components becomes an important competitive advance. That is why Faber-Com provides in its kit:

- The electronic interface card for the external steering input;

- The Scanreco radio remote control, already configured to drive the truck;

- A complete wiring;

- A dedicated tower light with acoustic alarm.

The same applies to other solutions by Faber-Com (e.g. for truck mounted cranes, aerial platforms, concrete pumps and other), where supplying a complete bundle with radio remote control, moment limiter, inclination sensors and joysticks is an added value.

E.E: How has the customer profile changed lately?

Faber-Com: Nowadays, the profile of the people interested in the integration of electronic control solutions is becoming more and more complex and differentiated. Sectors that have always been cautious towards the adoption of electronic controls (such as small agricultural machinery, forestry, utility vehicles and other) are progressively starting to evaluate these solutions.

In this sense, the ability to keep up with these new market trends and develop an ever wider knowledge about the requirements of each application is essential.

E.E: Given the current context, was there a need to diversify the portfolio of services / products?

Faber-Com: Faber-Com produces a complete range of solutions for the control of mobile hydraulic machines (ranging from joysticks to electronic cards, from inclination sensors to safety devices for lifting machines), so somebody might say that apparently there is no need to further diversify its portfolio.

However, that is not true, because the key to effectively compete in the current context can be summarized in one word: customization. That is the reason why the company has specialized in providing tailor-made solutions. This not only implies the need to continually widen its product range, but also represents, together with its R&D long-term activity, an important driver for the conception of new innovations.

E.E: What was the most important project this year?

Faber-Com: As we all know, COVID-19 has led to social distance and global uncertainty, heavily affecting the traditional communications channels for companies, especially in the B2B sector.

For this reason, in 2020 Faber-Com started an ambitious project of renewal of its digital presence, which included, but was not limited to:

- The participation to different digital events and shows;

- The translation of its website in more languages and the inclusion of new pages with technical information, presentations of specific integrated systems and more.

An increasing attention to providing tutorials and technical assistance to its customers, also through its YouTube channel

Of course, the importance of these tools is supposed to keep rising in the future, so the company aims to foster this aspect in conjunction with its usual orientation to the direct contact and support to its customers.

E.E: A short year-end message for collaborators.

Faber-Com: 2020 has certainly been a difficult and complex year, which represented an important challenge for Faber-Com.

Therefore, if today we can celebrate the positive results just described, we owe it to the hard work of all our team, as well as the priceless support of our partners, customers and suppliers. For this reason, there is only one message we wish to share: thank you to all of you!

FABER-COM SRL

Via Romana, 36/1 – Poviglio (RE) 42028

Email: info@fabercom.it

Site: www.fabercom.it