FAT was born in Barcelona in 1963 as a company dedicated to the sale and manufacture of textile accessories. Due to the industry crisis in the late 60s FAT readapts its business model, thanks to the founder’s knowledge in engineering, to start manufacturing and commercializing machines for cutting ferric materials. Over the years, FAT has specialized in the study of workflows of each client, customizing projects and designing cutting equipment, cutting machines, combined systems and smart warehouses.

Easy Engineering: What are the main areas of activity of the company?

FAT: FAT is part of the industrial machinery and tool sector. We fabricate and distribute machines for the cutting of metal profiles and accessories.

The FAT brand is recognized nationally and internationally for the quality of our machines and services. From the FAT headquarters, we offer specialized technical advice, project study and design, spare parts service, and technical service. In addition, we have a technical support network in all the countries in which we operate.

E.E: Which are the novelties for 2021 about new products?

FAT: At FAT this year we wanted to integrate creativity and innovation into our catalogue.

Thus, this is what we would like to talk about next, our challenges for this 2021.

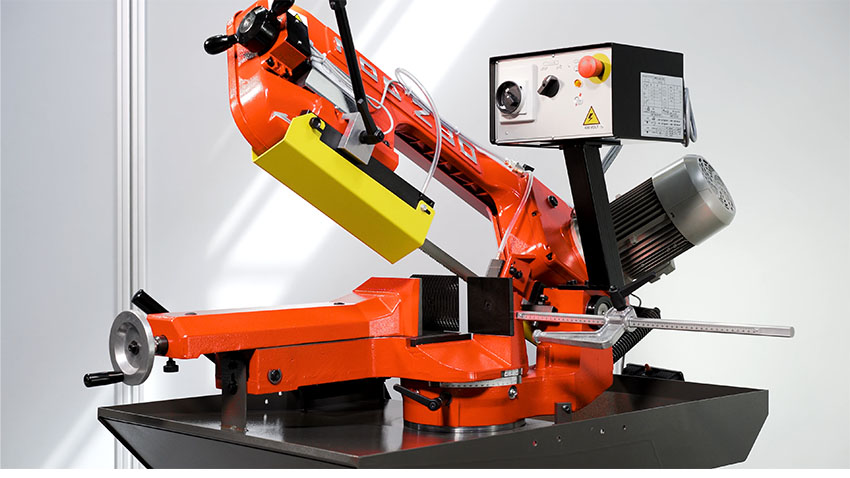

The integration of a new category into the FAT tape saw ranges: The economical fixed automatic machine range (AFE). It is a high-performance equipment, with the ability to offer a high quality in the processing and a good execution speed with the difference that its price is more affordable than the top range saws that we continue to manufacture. In this range, the hydraulic cylinder has been positioned at the rear of the arc and that has allowed a significant saving in costs when it comes to manufacture, without losing too many benefits of automatic models manufactured to date.

Within our extensive catalog, we also offer a wide variety of cutting disc machines, but among them, we highlight the cutting disc machine of high productivity and efficiency DT-100. Focused on the production of cutting solid parts, its power is exceptional and is also totally under control in each cut. That is why this equipment is essential for companies that need continuous high performance.

New cutting equipment developed by our FAT team is the belt saw for corrugated bundle cuts. Cutting corrugated bundles has always been characterized by the difficulty in keeping all bars in the package steady. This equipment has been designed to hold the material with chain mooring vices that manages to eliminate the movement of the bars.

460 TCT, our tail system helps our machine to take advantage of the material until its end, as the cutting vice is also a feeding vice. This means that when the feed vice has lost the material, the cutting vice “grabs” it, feeds to the desired position and cuts “behind” the saw. That is, we can have a cut at 1 mm. From the end of the bar.

Finally, we want to highlight our most creative and pioneering project in our sector in Spain: The Virtual Reality project for cutting equipment. Considering the digital transformation of our society, FAT has taken the initiative transformed our projects into a digital environment to be able to transport our equipment easily and sustainably to the home of our customers, fairs and events using minimal space.

We introduced all those new products and services in January in a unique online event that you can watch in our Youtube channel. (https://youtu.be/vUEnEwIi8JU)

E.E: What are the product ranges?

FAT: Iron range:

Both manual, semi-automatic and automatic band saws have management of all machine movements by CNC. Manual and semi-automatic cutting disc machines. Cutting equipment with HSS disc and automatic carbide disc.

Aluminium range:

Machines for cutting, punching, drilling, threading and milling special parts from bar material or cast parts.

Machining machines. Double-headed cutters. Manual, semi-automatic and automatic cutters. Milling machines. Copiers. Bending machines. Cross-cut saws.

Accessories:

Roller tracks, Roller adapter, dry cutting device, vice pressure regulator, bundle clamping device, electronic speed inverter, motor drive, swarf extractor, gravity downfeed, ski stop, pneumatic vice, saw control device, optical control device for saw position (laser), automatic arc rotation device, feedback with visualizer, ruler with linear guide saw blades and spare parts for machines and cutting equipment.

E.E: At what stage is the market you are currently active in?

FAT: We are in a very mature market all over the world. In some fields the technology that changed in the 1980s is remaining today, but it helped us to improve processes by automating our equipment.

E.E: What can you tell us about market trends?

FAT: There are other technologies that are being introduced such as cutting laser or additive manufacturing, that involve modifying production processes for our customers and are a great challenge for the metal sector.

E.E: What are the most innovative products on the market?

FAT: FAT’s range of TCT band saws are a range of high-performance, dual-column programmable automatic band saws with a laser-based system to detect size of its start and tail. This machine can cut up to the last millimeter, making the final portion of each profile a valid piece. It incorporates a 7″ touch LCD and a state-of-the-art system based on the ARM40 processor, also an RJ45 Ethernet network connection that allow our clients to manage and monitor the machine with the appropriate software.

E.E: What estimates do you have for 2021?

FAT: The year we just left behind involved a worldwide slowdown that affected all strata of society. All economic sectors had higher or lesser impacts.

From FAT, we are sure that this 2021 will be an important year. A period of great growth and with great innovations in our sector and others. Every great crisis shows the talent and wit of humanity.