Feistmantl Cleaning Systems was founded in 1990 by Manfred Feistmantl, who gained years of experience in industrial cleaning and recognized early the need for container cleaning systems. The company has excellent technical know-how and offers customer-oriented solutions. In the meantime, Feistmantl Cleaning Systems has become one of the most renowned and market-leading manufacturers of waste container cleaning systems in Europe. The modern equipped planning and design offices in the own production facility in Tyrol (AUSTRIA) and the suppliers selected according to the international quality standard (IQS) guarantee above-average quality in all areas of container cleaning technology.

Interview with Adis Katkic, M.Sc., Sales and Marketing at Feistmantl Cleaning Systems.

Easy Engineering: What are the main areas of activity of the company?

Adis Katkic: Feistmantl is a manufacturer of cleaning systems. For over 30 years, the company has excellent technical know-how and offers customer-oriented stationary solutions for waste garbage can cleaning, drum cleaning, pallet box cleaning, IBC container cleaning, tank cleaning and container cleaning.

E.E: What’s the news about new products?

A.K: We develop and implement innovative machines for environmentally friendly and resource-saving cleaning tailored to the needs of the customers. Therefore, new systems will be designed in such a way that they can be used without any problems for operation with environmentally friendly systems like photovoltaic/solar system, heat pump and rainwater tank. Feistmantl is also working on connected systems to collect and process usable data for smarter cleaning and maintenance.

E.E: What are the ranges of products?

A.K: Feistmantl offers principal stationary cleaning systems but also has one mobile system in assortment.

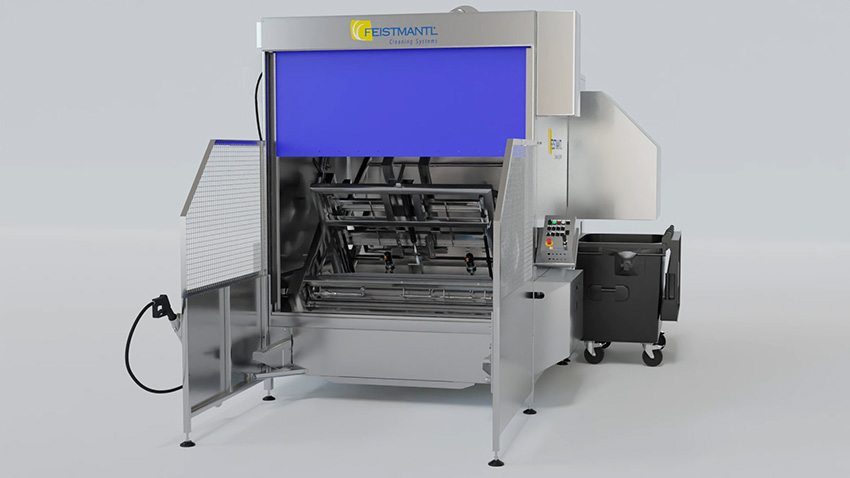

Stationary systems are separated in entry level semi-automatic BWA series, fully automatic BWK series and individual fully automatized DWA/CRA systems.

In addition to this Feistmantl offers usable work aids and accessories for the bin/container cleaning area.

E.E: At what stage is the market where you are currently active?

A.K: Waste bins need to be cleaned regularly to keep them aesthetic, not to develops an unpleasant smell or don’t to have residues which can damage the manufacture. In most cases, industrial washing systems are used for this, although the requirements for such systems are very different. Due to the recent Covid crisis, but also the increasing hygiene awareness in waste management and industry, the market is in constant growth. We are currently expanding throughout Europe and are using our successes and many years of experience from the DACH countries market, but we always strive to find strong and reliable partners for our products worldwide.

E.E: What can you tell us about market trends?

A.K: Global waste management is a rapidly growing market. Factors such as the growing world population, increasing industrialization in developing countries and increasing awareness of recycling economy advance growth. So, it is obviously that the need for innovative and professional cleaning systems is increasing. Where performance and job creation were used to be in the foreground, nowadays, due to the shortage of staff the job upgrading, the hygiene and the degree of automation is getting more important. Rather, customers prefer systems that make daily work activities more attractive, user friendly, more ergonomic, and ecological friendly.

E.E: What are the most innovative products marketed?

A.K: Our most innovative product in the field of stationary container cleaning systems is used for the automatic cleaning of waste containers with a capacity of up to 1100 liters. This system (BWK1300) is available standardly with a remote maintenance software, individually adaptable program sequence and optionally with water recycling system and many more. The power supply by renewable energy, a thermal heat pump and rain water use is of course possible on request.

E.E: What estimations do you have for 2023?

A.K: With the COVID crisis and the Ukraine war, a very turbulent year came to an end. We all hope that this year will be a little bit calmer and that there will be more stability on the procurement market in terms of prices and availability. As a result of the crisis, we are noticing very positive developments in the area of fully automated continuous flow systems, where we have great expectations, but also with the proven semi-automated systems.