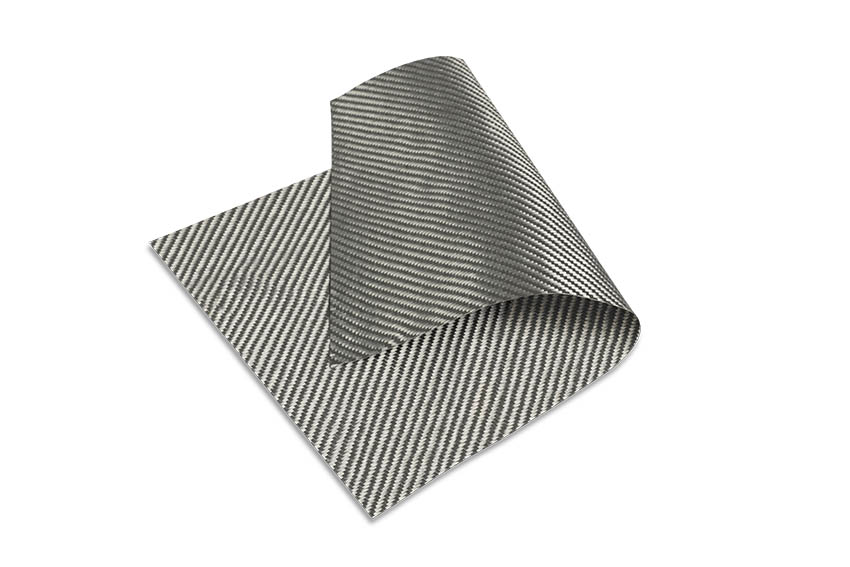

FibreCoat develops and markets high-performance fibre materials. The aluminium basalt fiber “AluCoat” is the first market-ready product. Unlike currently used conductive polymer yarns, AluCoat is thermally and electrically conductive as well as temperature resistant up to 600°C. Compared to pure aluminium fibers, AluCoat can be produced at one-tenth the cost.

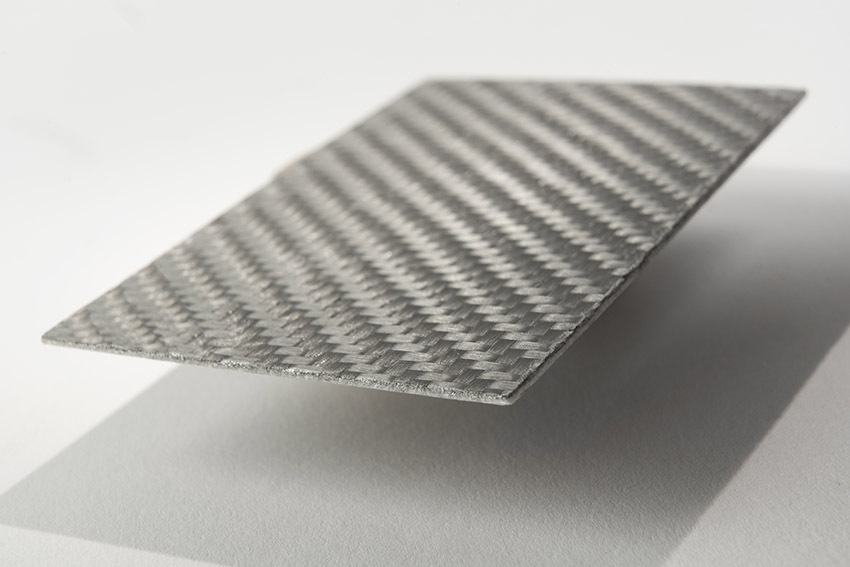

As a result, the material has the potential to become the much-needed, affordable shielding material for the electromagnetic shielding of electric cars and 5G devices of the future. Until now, FRP components have only been used in high-end products. The company’s polymer-coated glass fiber “PolyCoat” achieves a cost advantage of about 30% compared to the state of the art in pure composite production to make FRP more affordable. Thanks to improved mechanical properties, components can be designed up to 40% lighter.

Easy Engineering: What are the main areas of activity of the company?

FibreCoat: Applications are body parts in automotive engineering, housing parts of portable electrical appliances and other end-use areas

E.E: What’s the news about new products?

FibreCoat: FibreCoat developed a unique coating technology to produce bi-component fibers. The innovations core is the coating of each individual filament. A special plant design enables the production of such a material for the first time. Value is created by implementing this technology on an existing fiber production line. A patent on multi-component fibers with a thermoplastic sheath was already disclosed in April 2019. For the aluminium-coated basalt fiber, the patent is about to be disclosed

E.E: What are the ranges of products?

FibreCoat: We have two different fibres in our range. The aluminium coated fibres and polymer coated fibres. The polymer coated fibres are still in development and we expect to start production in 2022.

E.E: At what stage is the market where you are currently active?

FibreCoat: We are currently delivering to our first customers who are testing our materials and finding new applications everyday.

E.E: What can you tell us about market trends?

FibreCoat: With the rise of 5G and IOT we see an increasing demand in EM-shielding. This is where our aluminium coated shines, due to it being lightweight, cost reductive and versatile. An additional trend is sustainability, thanks to our unique production we greatly reduce our power consumption and the fibres are easily recyclable as there is only basalt and aluminium used.

E.E: What are the most innovative products marketed?

FibreCoat: This is our Aluminium coated fibre. (see above)

E.E: What estimations do you have for 2022?

FibreCoat: In 2022, we expect to grow exponentially, by increasing our production combined with our marketing campaign we strive to make our high performance material affordable and accessible for everyone. We are also planning to start the production of our polymer coated fibres in the 2nd quarter of next year.