FIPA is a specialist in vacuum, gripper and lifting technology. The internationally active company develops and distributes quality products and innovative system solutions relating to material flow. FIPA GmbH was founded in 1985 and employs around 60 members of staff at its headquarters in Ismaning near Munich. With a subsidiary in the USA and representative offices in Hungary and China, FIPA also has an international presence.

Interview with Steven Higgins, International Sales Manager at FIPA.

Easy Engineering: What are the main areas of activity of the company?

Steven Higgins: Efficiency and flexibility are key success factors. FIPA’s answer: an innovative product portfolio. It incorporates trends in robotics and provides customized solutions for the automotive industry and its suppliers. FIPA specializes in the areas of gripper assembly, vacuum and lifting technology and is one of the medium-sized players in the industry – another important advantage for customers. This means that systems and applications can be quickly adapted to changing market conditions or redeveloped.

For automated material flow and manual handling of loads, FIPA offers components such as grippers, gripper fingers and air nippers as well as complete systems. Quick-change systems ensure dynamic handling and minimum downtime. FIPA offers an ideal blend of vacuum cup geometry and material properties. Due to their flexibility and process safety, FIPA vacuum cups have proven themselves in a number of areas; these include the automotive and sheet metal industry, the plastics and packaging industry as well as the logistics sector.

Thanks to its expertise in gripper assembly and vacuum technology, FIPA can also meet individual requirements. No matter whether you are looking for the highest energy efficiency, the longest service life, the best possible gripper dynamics, fragile, heavy, oily or rough workpieces which need to be moved – FIPA accepts the challenge.

E.E: What’s the news about new products?

S.H: New area gripper series for the automated handling of goods

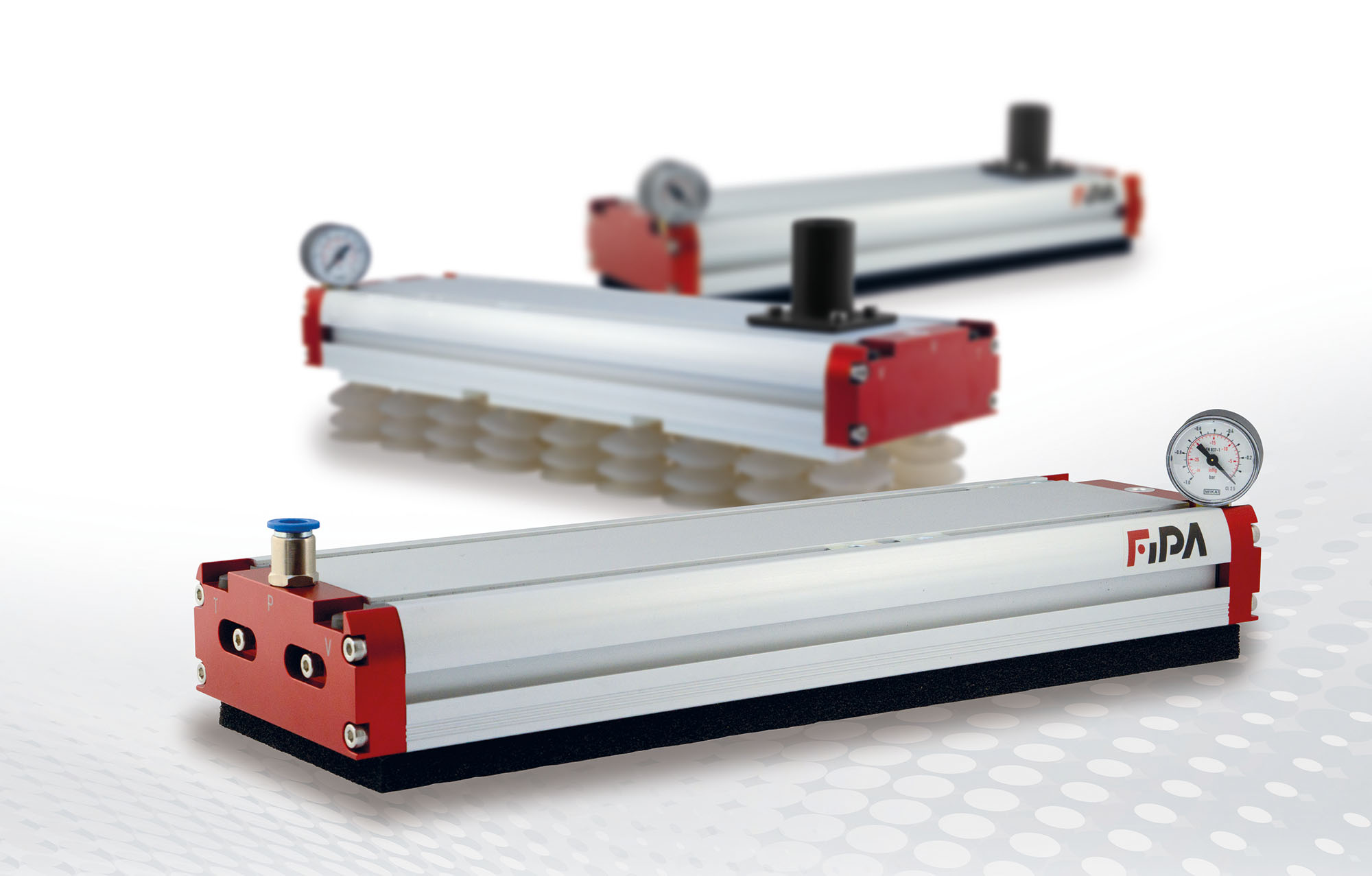

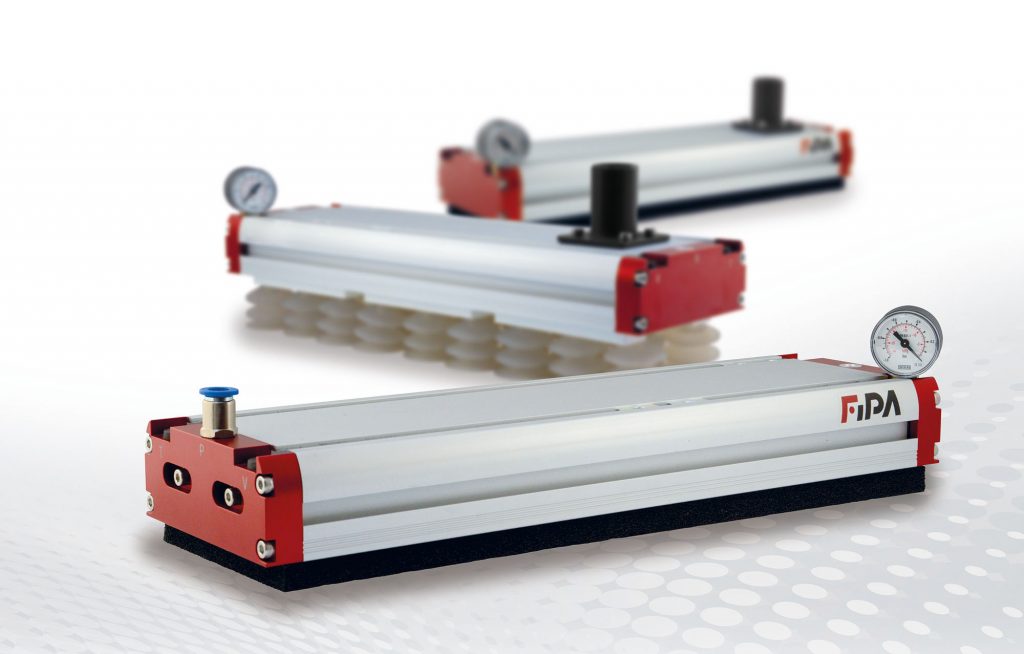

Robust, resistant, reliable: FIPA GmbH has expanded its End-of-Arm-Tooling range with the FSG area grippers. The new area grippers are available with a low-wear sealing foam or two sizes of plug-in vacuum cups plus optional vacuum supply.

Grip and move products or product layers dynamically and reliably without changing grippers: The FIPA area grippers of the FSG series can be used almost anywhere where the handling of larger parts is required. Typical applications can be found in the packaging industry.

Thanks to construction from an extruded aluminum profile, customers benefit from an optimal price-performance ratio. Compared to steel designs, grippers made of aluminum have a lower weight and thus score with a higher net payload – an advantage in robot applications. Lightweight aluminum components save operating costs and ensure a high level of energy efficiency. A transfer line for compressed air or vacuum is built into the new area grippers. When connecting several area grippers together, this built-in line eliminates the need for compressed air or vacuum lines on the housing.

Versatile due to several variants

A reliable vacuum supply is indispensable for the automated handling of goods. Depending on the installation environment and application, area grippers FSG are available either with integral ejectors or with a connection to the central vacuum supply. Integrated ejectors reduce noise emissions and thus help ensure a pleasant working environment in the packaging area. Since the selection of the appropriate vacuum generator is determined by several factors, FIPA will of course support you in customizing the vacuum system. This will see you benefit from our technical expertise and many years of experience in project management.

Variants with flow reduction or check valves reduce leakage if, for example, cardboard does not completely cover the gripper surface. These variants prevent too much air from being sucked in and the vacuum from collapsing. Variants with check valves can grip goods securely during swivelling and tilting movements of up to 90 degrees.

FIPA can optimally adapt the area grippers to the customer’s application through further customized modifications.

New ejector ranges for flexible vacuum generation on site

FIPA GmbHhas added the FBM, FGS and FMC series to its lineup of ejectors. The new vacuum generators, with different vacuum flows and functionalities, cover various application areas in the handling of goods and make a perfect match to FIPA’s high-quality components for vacuum and gripper technology.

FBM – small and silent

Due to their compact design, the mini multi-stage vacuum ejectors of the FBM series are best suited for the quick pick-and-place of small workpieces and the dynamic handling of porous materials, such as cardboard. Their low weight, small dimensions, internal silencer and several mounting holes mean that they can also be used as inline vacuum generators in which the vacuum cups are mounted directly on the ejectors.

FGS – efficient and space-saving

The heavy-duty inline vacuum ejectors of the FGS series can be mounted on gripper base plates or directly on robotic arms. The installation of the vacuum cup on the ejector prevents losses due to leakages in hoses and ensures short evacuation times, which makes this series the perfect solution for pick-and-place applications.

Given its form factor, the FGS impresses with its high suction power. The version with a 3-stage chamber offers a suction power of up to 68 NL/min and the 2-stage version up to 46 NL/min using the same amount of compressed air. The FGS is equipped with a lightweight and robust aluminum housing and is also available with an optional silencer.

FMC – the Hercules among ejectors

With a suction power of 360 to 1260 NL/min, the multi-stage vacuum ejectors of the FMC series occupy the top spot in FIPA’s lineup of ejectors. The high-performance FMC ejector has all applications with a high leakage rate firmly under control. This makes it the perfect product for use in the packaging industry.

The numerous mounting options facilitate the design of grippers. The FMC is equipped with a screw-on vacuum gauge at the factory to enable easy monitoring of vacuum generation in the system.

The version with a non-return valve can maintain a vacuum for a short time – depending on the porosity of the workpiece and the leakage – even if the compressed air supply fails.

The FORMHAND technology

FIPA GmbH has entered into a strategic partnership with FORMHAND to add a new universal gripper to its portfolio. As a universally applicable and innovative gripping system, the FORMHAND replaces many product-specific solutions for making production and logistics more flexible, where goods of different shapes are moved.

Production and in-house logistics are becoming increasingly complex and require efficient solutions to handle a wide variety of handling processes. The clever combination of tube lifter FIPALIFTpro and FORMHAND gripping pad safely picks up goods weighing up to 25 kg where conventional solutions with vacuum cups fail. These are objects without a flat surface and flexible goods, such as shrink-wrapped PET bottles or tinned food.

The universal gripper consists of a freely deformable gripping cushion filled with granulate. The cushion nestles closely to the surfaces of the goods and thus forms a sealed system. As soon as a vacuum is applied to it, it becomes firm and fixes the gripped object. This enables the FORMHAND to gently pick up objects with complex geometries. Ergonomic handling of goods in a wide variety of shapes can thus be realised economically without changing grippers. The only condition is that the gripping surface is completely covered by the object. This saves users high costs of special grippers. Moreover, set-up times are eliminated.

The gripper pad has a large, rectangular suction surface of 300 mm x 200 mm and can be changed without tooling. A quick-change adapter connects the FORMHAND to the FIPALIFTpro tube lifter. The FORMHAND technology is also used on classic industrial robots or cobots. Three different sizes are available here. The smallest gripping module has a diameter of 80 mm and lifts up to 2 kg reliably. Due to its size, it can therefore be ideally integrated into collaborative applications.

E.E: What are the ranges of products?

S.H: Vacuum

- The world’s largest selection of vacuum cups: flat, bellows and oval vacuum cups

- Ejectors, pumps and side channel blowers

- Vacuum filters

- Control technology

- Valve technology

- System monitoring

- Lifting cylinders

- Tubing, connecting elements

Gripping

- Grippers

- Gripper Arms

- Air Nippers

- Quick-change systems

- Area Grippers

- Extrusion systems

- Linear Technology

- Accessories, such as electronics & sensors

Lifting

- Tube lifters FIPALIFTpro and FIPALIFTmax

- various suction feet

- FIPA Spider vacuum lifter

- FORMHAND universal gripping pad for FIPALIFTpro

E.E: At what stage is the market where you are currently active?

S.H: The market for Automation and Robotization is growing year on year currently standing at around 113 robots per 10,000 workers where in 2015 this figure stood at 66 units; each robot requires some form of end-effector or gripper and this is where FIPA’s portfolio comes in supplying a full range of gripping solutions in terms of mechanical and vacuum gripping for example our SBX-F area grippers as well as vacuum generation and End of Arm Tooling (EOAT) components.

This industry growth also includes semi-automated products not necessarily to streamline processes but as a way to meet employers growing corporate responsibility in improving health and safety to reduce risk but also providing solutions to the developed world’s aging workforce ways to continue working in demanding environments whilst also increase productivity, the FIPALIFT range has been developed to meet this need.

E.E: What can you tell us about market trends?

S.H: As touched on above we see a corporate change in what is acceptable within the workplace, this can be from a variety of angles ultimately leading to automating processes. Traditional practices are no longer acceptable in terms of heavy or repetitive lifting added to an aging workforce, this is leading businesses to search for solutions such as FIPALIFT which can reduce the load on the human body by up to 87%, particularly useful where perhaps a process cannot be automated as a result of physical space constraints, possibly where human input is vital within the process or simple budget restrictions.

E.E: What are the most innovative products marketed?

S.H: These have been detailed in the answer to question 3, but briefly the Form-Hand, Area Gripper SBX-F.

E.E: What estimations do you have for 2022?

S.H: Covid has created a pent-up demand through 2021-2022 which has had an impact on rising global supply shortages and rising energy costs despite this we see the market continuing to grow as demand continues. FIPA will continue it’s internationalization by working with new sales channels and partners in specific industry segments, along with innovative new products our aim is to optimize our processes to achieve marginal gains that collectively add up.