Flexlog GmbH is an innovative company based in Karlsruhe (Germany) and was founded in 2012 as a spin-off from KIT. With the claim to fundamentally change the conveyor technology and intralogistics industry, flexlog has developed highly flexible and decentralized control concepts and conveyor technology components.

The entire development of software and hardware products is carried out in-house and the focus here is on a holistic approach so that the customer is offered a complete, customizable and scalable solution.

Easy Engineering: What are the main areas of activity of the company?

FLEXLOG: Flexlog is the point of contact for intelligent system planning, flexible control concepts and modern software solutions in the intralogistics industry. The development of decentralized control and material flow systems for conveyor systems is the focus of product development.

E.E: What’s the news about new products?

FLEXLOG: Our visualization software has developed into an IIoT platform for a holistic solution for the visualization and optimization of intralogistics systems that can support the entire team with the help of intelligent systems. A native iOS app has recently been available for this purpose, which enables access to plants and systems via app and sends push notifications for status updates directly to the smartphone.

In addition, our product range of our control modules has been expanded with a WLAN module. This enables a wireless connection of conveyor technology components so that, for example, AGV fleets can be connected to a continuous conveyor system.

E.E: What are the ranges of products?

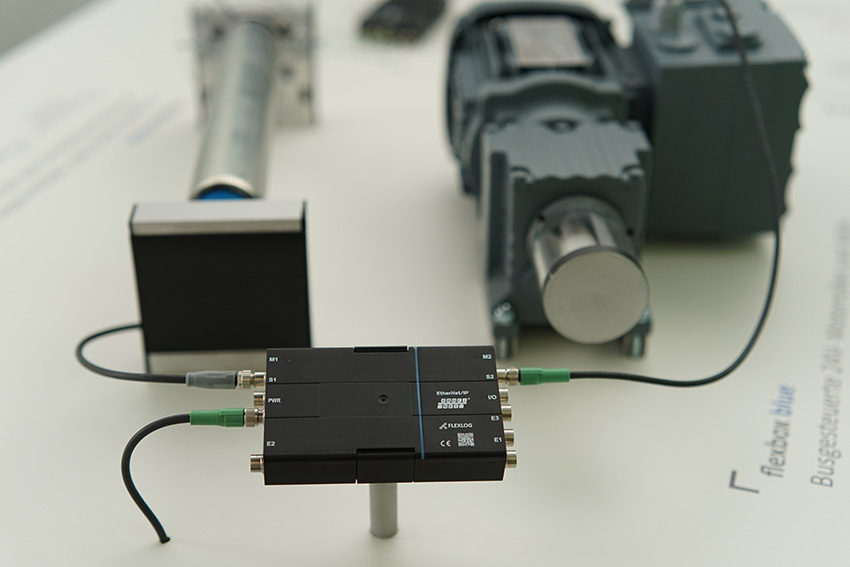

FLEXLOG: Our product portfolio for plug & play capable conveyor technology essentially consists of our flexboxes. A flexbox is a Profinet and Ethernet / IP capable control module, which can be put into operation as a simple I / O module over autonomous sections up to a fully plug & play capable flex conveyor system. The WLAN module Space, for the quick and easy networking of systems and field components via radio link, was newly developed this year and enables a smooth transfer between continuous conveyor technology and driverless transport systems, for example.

As a pure software product, we offer our IIoT platform HORIZON, a holistic solution for the visualization and optimization of every intralogistics system. It has a modular structure so that the customer receives a customizable but scalable software solution for his individual conveyor system. The modules are visualization, material flow controller, maintenance, ticketing and analysis.

In addition, flexlog offers all kinds of accessories for conveyor systems, including sensors, industrial switches or power supplies.

E.E: At what stage is the market where you are currently active?

FLEXLOG: Central controls by means of so-called “programmable logic controllers” (PLC) are characteristic for the planning, assembly and commissioning of conventional conveyor systems. As a result, the end customer is confronted with costly project planning, programming, control of sensors and actuators, extensive assembly and electrical wiring as well as time-consuming commissioning.

In modern automation technology there is an increasing tendency to use autonomous, decentrally controlled and intelligent systems that are networked with one another and can solve tasks independently.

E.E: What can you tell us about market trends?

FLEXLOG: In relation to the already mentioned approach to decentralized control, companies expect shorter periods of time for the implementation of logistics orders, which requires less implementation effort, high flexibility, high throughput rates and minimal waiting times. In addition, customers want a conveyor system that can be handled and reconfigured by its own operator so that external maintenance can be dispensed with and costs can be minimized during operation.

E.E: What are the most innovative products marketed?

FLEXLOG: Our flexbox options – the flexbox orange, flexbox green and flexbox blue! The Profinet and Ethernet / IP capable control modules offer everything from simple I / O modules to plug & play capable, decentralized control and decentralized material flow computers – even with the most complex conveyor systems.

Our flexbox solutions have already been awarded the VDI innovation prize and are a milestone in conveyor technology development. The high degree of flexibility and autonomy, as well as the simple handling and user-friendliness, can make intralogistics processes significantly more efficient. The intelligent controls and patented algorithms developed by flexlog recognize topologies independently and calculate dead- and lifelock-free routing strategies so that they can completely replace a central material flow controller.

The modules are easily networked via Ethernet, which means that branches can be made without additional effort. External devices can also be integrated with local evaluation. The flexbox orange can be controlled autonomously without an additional PLC. With our green solution, the entire material flow can even be regulated and monitored autonomously via the modules.

All products can be configured via a website, our green solution even maps the entire system with all the information so that the entire process of your system becomes transparent. Due to this fact, we guarantee simple maintenance with recording and evaluation of individual operating parameters in the sense of predictive maintenance and a continuous online update.

Thanks to the simple assembly concept and plug & play, very short commissioning times can be achieved, so that the conveyor system is ready for use in next to no time. With our IIoT platform HORIZON you can also get a visualization and an optimization tool for the conveyor system. That means transparency for the customer and profitable use of a modular conveyor technology concept.

E.E: What estimations do you have for 2022?

FLEXLOG: We expect that we will be able to convince other conveyor technology manufacturers and customers who need an intralogistics system of the advantages of our modular, flexible and intelligent approach and we are looking forward to many exciting projects! We are also pleased that we can be represented at the LogiMAT trade fair again next year!

Thomas Bartmann,

Sales Director / Member of the Board