Flo-Tite provides a standard of engineering excellence to the process market with proven success in some of the most hostile conditions known to the industry. Through the efforts of Flo-Tite’s engineers and sales representatives, they have solved many of the industry’s demands for a quality, reliable, efficient, and safe ball valve over the last 20 years. The company’s valves are implemented in many markets and industries throughout the U.S. and many other countries. Products selected are subjected to the rigors of a product research and development program. The completion of this process produces a safer, more efficient ball valve product.

Easy Engineering: What are the main areas of activity of the company?

Flo-Tite: We strive to be our customer’s “One-Stop-Shop” for all their valve and automation requirements.

Industries serviced by Flo-Tite include:

- Petrochemical

- HVAC

- Municipal (Water & Food)

- Pulp & Paper

- Food & Beverage

- Chemical Process

- mining

- Iron & Steel

Flo-Tite’s valve products design priorities include:

- All-inclusive basic models to allow the customer the greatest flexibility of multiple applications from a single product.

- Increase the interchangeability while reducing the number of components and allied accessories, permitting the customer to minimize inventories and positively affect their flexibility and bottom line.

- Continually improve the quality, efficiency, and safety of all products.

- Be innovative while maintaining computability with customer satisfaction.

E.E: What’s the news about new products?

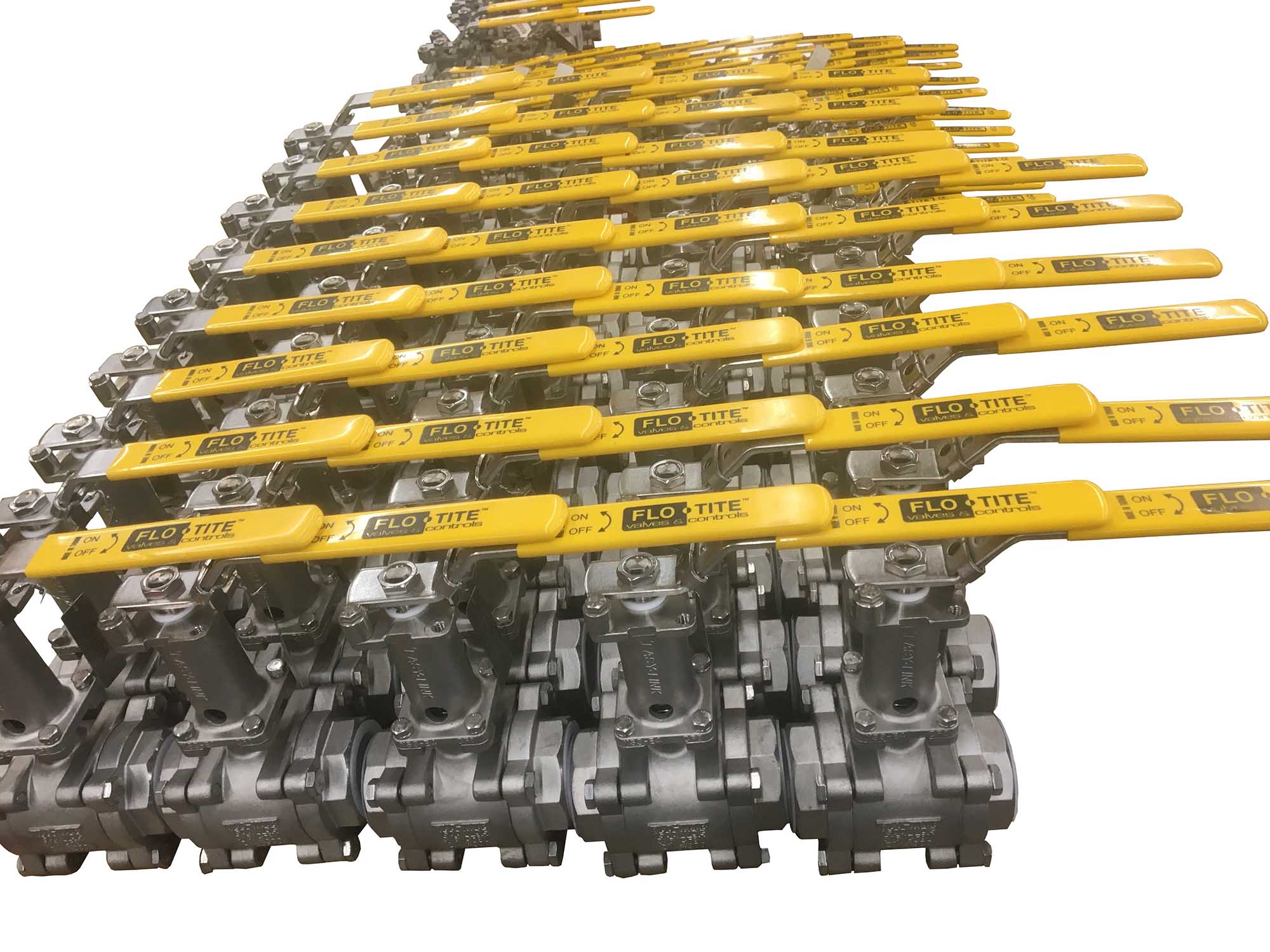

Flo-Tite: Flo-Tite’s newest products are the HPF-3000. This 3-piece valve can handle a working pressure of 3000psi and a burst pressure of 7000psi. We are also offering a new AirCon Actuator model SR/Da 115.

E.E: What are the ranges of products?

Flo-Tite: Flo-Tite Inc. is a manufacturer of high quality ball valves and actuation equipment. Our products range from standard commercial type Ball Valves to high-pressure metal seated Control Valves. We maintain an inventory of standard valves in Carbon, Stainless Steel and Alloy 20. All Valves are manufactured in strict adherence to internationally recognized standards and specifications, including ANSI/ASME/ISO/NACE and API. In addition to our standard products, we welcome the opportunity to design special Ball Valves and Castings for OEM requirements.

We also offer a wide range of butterfly valves within our Max-Seal butterfly valve company.

E.E: At what stage is the market where you are currently active?

Flo-Tite: Flo-Tite Valves and Controls is positioned to meet demands for innovative products with old ways of doing business made easy. Our style is to move forward, keep promises, and hit our targets. We are a company that is fiercely dedicated to ideas, energy, innovation, and stamina that is needed to meet the extraordinary challenges of this new world market.

You will find the most impressive fact about a Flo-Tite product is the product itself.

E.E: What can you tell us about market trends?

Flo-Tite: Even though the U.S. economy has not been consistently stable, we continue to see impressive growth. Projects in which were put on hold during COVID are now coming back to life.

E.E: What are the most innovative products marketed?

Flo-Tite: Being able to customize our valves to meet our customers’ specs or requirements, allows us to design innovative products daily. Our media containment device helps our customers minimize fugitive emissions, while also allowing maintenance engineers to fix a valve stem leak on the spot without having to shut the lines down. This saves the company and maintenance time and money.

E.E: What estimations do you have for 2022?

Flo-Tite: I think we will continue to see tremendous growth in the industrial valve industry as the world strives to reduce pollution, creating alternative sources of energy.