Flott is a manufacturer of drilling, grinding and sawing machines and has been producing machines of the highest quality at its Remscheid site since 1854. The FLOTT brand has become known beyond the country’s borders as a pioneer and innovation leader in drilling technology. As a pioneer and co-inventor of drilling technology, the company is now managed by the 6th generation of the family and focuses today on the innovative further development of its proven products. High quality made in Germany is the lived philosophy of the company, which to this day produces all its drilling products in-house and is constantly developing them further.

Due to the great wealth of knowledge in the field of drilling, Flott has meanwhile taken up the cause of digitalising drilling machines and processes. Because of this, FLOTT’s PLUS machines are equipped with digital touch operation and a uniform control system that promises time-saving and advanced machining of all types of materials.

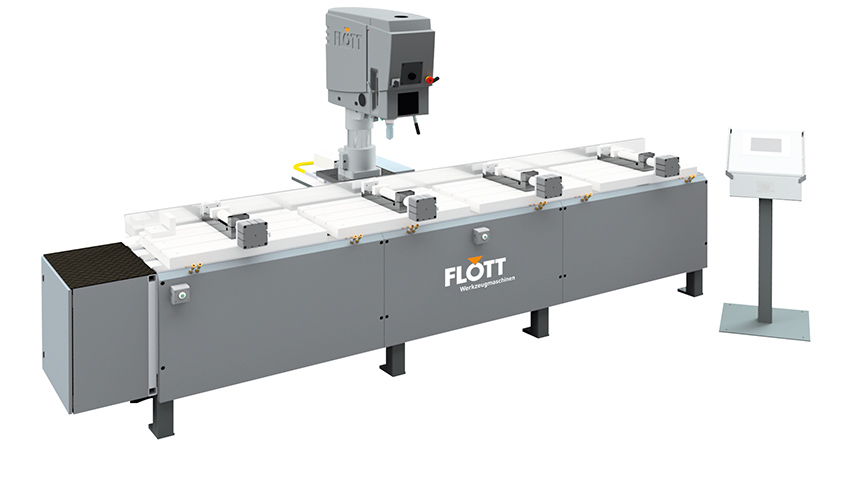

In addition, the company is the only manufacturer with an NC machine in its range. With this machine, the Z-axis can be controlled fully automatically, so that entire drilling programmes can be stored and processed within the machine. The CNC PLUS drilling line, which is related to the NC machine, offers a complete solution in the field of drilling beams, pipes and similar materials. FLOTT thus produces a fully automatic drilling product which can be individually adapted to the customer’s needs.

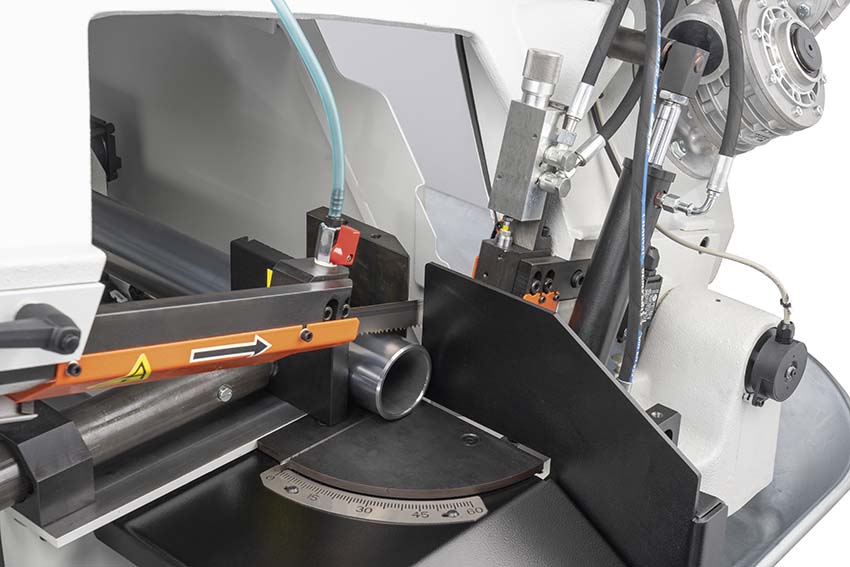

In addition to drilling machines, FLOTT also sells machine tools for sawing and grinding. Especially in the field of grinding, FLOTT stands for high quality and work safety.

Easy Engineering: What are the main areas of activity of the company?

FLOTT: 165 years of manufacturing the machines have resulted in a high level of expertise that is unrivalled on the market. FLOTT is unique in the technical implementation of modern operating functions and is therefore the market leader for industrial drilling machines and training workshops in Germany. Also within Europe, but especially in the DACH area, the drilling machines of the PLUS & Classic lines are in demand as never before.

E.E: What’s the news for 2021 about new products?

FLOTT: After we have managed to expand our innovative PLUS series in 3 platforms (10-70mm), the focus for 2021 is primarily on NC or CNC machining in drilling and sawing. By automating our drilling machines, the customer should be relieved of steps that were previously necessary in order to increase the efficiency of the work in the workshops and production halls. Flott now has up to three axes which carry out the drilling process fully automatically and without manual operation. The same applies to the fully or semi-automatic sawing machines.

In addition, FLOTT will revise and relaunch the robust and proven classic machines in 2021. The machines, which have been available for more than 30 years, are to convey the familiar stability with a new look. It specifically addresses customers who do not require technical and innovative machines within their industrial production, but who consciously pay attention to ease of use and durability. As usual, the classic series will be priced below the PLUS series, so that Flott will have a solution for every customer and every budget in 2021.

E.E: What are the ranges of products?

FLOTT: At Flott, the focus is on drilling. In view of the fact that the company started its industrial career with drilling machines, a lot has developed here to this day. In the course of industrialisation, the FLOTT brand has made a name for itself through high quality and durability, which customers still trust today. Since only a few competitors promise and are able to deliver a similarly traditional and high-quality production, FLOTT continues to set the technical standards with regard to manual and automatic drilling processes.

In the drilling sector, FLOTT supplies the two lines mentioned, Klassik & PLUS, covering all application areas from simple hole drilling to complex deep hole drilling. FLOTT is now also regarded as an expert in flow drilling of all kinds and is able to carry out this machining in both very small and very large drilling diameters.

The other mainstays of FLOTT’s portfolio are grinding and sawing, offering customers a wide range of solutions from a single source. The main focus is on the high applicability, but also on the work safety of the machines, which is why our grinding products are becoming increasingly popular. All products deliver a uniformly high standard of quality, so that no wishes remain unfulfilled in the field of metalworking.

E.E: At what stage is the market where you are currently active?

FLOTT: The machine tool market has become highly technologised due to Industry 4.0 and CNC automation, which has resulted in a multitude of advantages within industrial production. However, the market for industrial drilling machines and grinding machines has remained unaffected. Since the products have sold themselves up to now primarily through their simplicity and technical applicability, there seemed to be no need to digitalise this branch of industry as well.

Since 2009, FLOTT has been focusing on occupying and further expanding the pioneering role in a market that has been little digitised up to now. The aim is to use the advances in technology to make drilling processes more efficient, simpler and safer.

Great successes have already been achieved since the beginning of the efforts. Within the last 10 years, sales – due to the new digital orientation of the machines – could be moved to a record high. The market for the new products is opening up noticeably, especially in Central Europe. While within the domestic market and in various neighbouring countries no drilling machine market would be conceivable without PLUS machines, internationalisation beyond this has so far proved more difficult. Within the countries with a relatively lower standard of development, customers tend to concentrate on the less technological and thus also significantly less expensive products. FLOTT counteracts this with the classic series, but still remains true to itself and consciously competes as a premium brand for users with high quality demands.

E.E: What can you tell us about market trends?

FLOTT: Basically, the machine tool market, like everything else, has adapted to the digital changes in the world, so that the overall standard for drilling, grinding and sawing products has also risen. In the course of globalisation, however, an enormously large number of products from low-wage countries have also entered the world market. Since these can offer their common customers a significantly lower price than producers from Western Europe without compromising on quality, even in markets with high quality standards there has been plagiarism, customer migration and a decline in the quality of the broad mass of drilling machines. Admittedly, FLOTT also had to contend with this fact, since until 2009 the products from FLOTT did not outwardly stand out from the masses, but were significantly more expensive. The significantly higher quality was not very noticeable due to the relatively universal design of all drilling products, so a solution had to be sought.

With the development and market launch of the PLUS series, FLOTT was able to reinvent itself externally. The quality of the machine became recognisable and over time it became noticeable that customers were reorienting themselves and consciously opting for higher quality. Today, almost 12 years later, FLOTT has revolutionised the market and set new trends, so that the competition in the high quality segment is trying to catch up. Today, digital drills are in demand like never before and FLOTT is confident that this development will continue.

Currently, new trends can be seen above all within application technology in drilling as well as in the digitalisation of products. After the successful digitalisation of our drilling line, the next thing on the list is the grinding programme. However, we cannot reveal any more at this point in time.

E.E: What are the most innovative products marketed?

FLOTT: The most innovative products from FLOTT are the SB 40 NC PLUS pillar drilling machine and the BA 30/40 CNC PLUS drilling line developed from it. Basically, however, the entire PLUS series can still be seen as the most innovative overall product, as it continues to change and develop the market for drilling machines to this day. So far, there is no end in sight to the development, so that great innovations from FLOTT can be expected in the future.

E.E: What estimations do you have for 2021?

FLOTT: We are planning 2021 to be a successful year in terms of both health and business. Assuming that the overall health situation improves by the middle of the year, we want to return to our usual strength in 2021 after small losses. The focus is on the one hand on the further development of our internal structures and on the other hand on the revision of our proven classic products. With two high-quality, up-to-date and durable machine lines in the future, we want to further increase our scope of action in Germany and also boost exports within Europe. We assume that with the return of freedom of travel we will be able to implement the measures we have been preparing over the past months. Together with our specialised trade partners, our goal will be to present FLOTT in Europe as a premium brand that meets the demands of our customers.

FLOTT stands for quality and durability – since 1854.