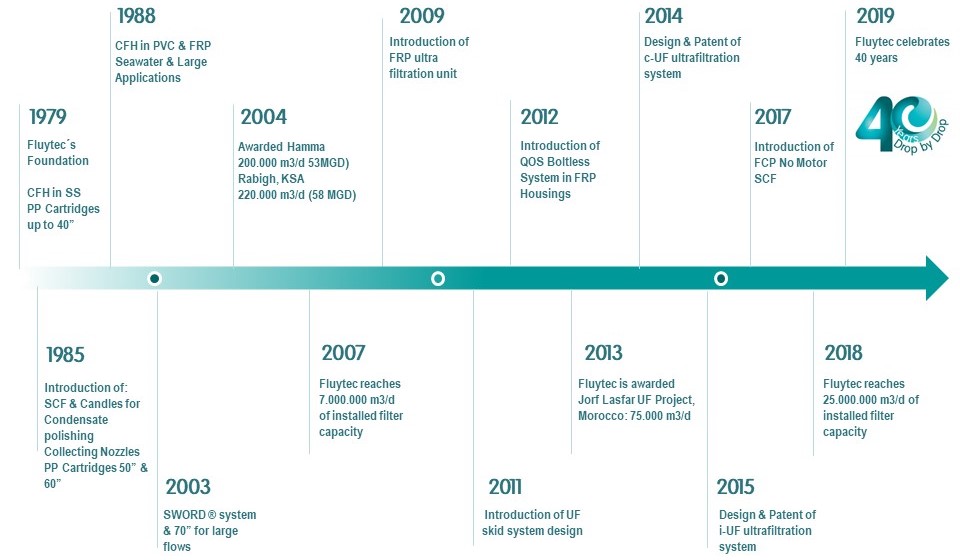

Fluytec is a Spanish Engineering & Manufacturing company in the field of liquid filtration. With over 40 years of experience, Fluytec is the global leader in several filtration markets, focusing in the development of new products and applications.

The company started working on the design and manufacturing of filtration equipment made of steel materials, supplied to several local industries and nuclear power plants among others, where Fluytec strengthened a solid Know-How from both, materials and processes point of view.

These roots enabled Fluytec to explore other applications for the same or similar technologies, which ended up into the development of FRP/GRP (composite) filter housings to be used in the incipient desalination market. Due to its superior corrosion resistance and other advantages, Fluytec became soon one of a kind, thus the leading worldwide supplier of premium filtration solutions for highly brackish and seawater desalination projects.

Easy Engineering: What are the main areas of activity of the company?

FLUYTEC: Fluytec excels in the pre-treatment of seawater desalination applications, with a wide product portfolio. In order to do so, there are several areas of knowledge that Fluytec focuses on: International Sales & Markets Development, Product Management, Project Management, Manufacturing, QC/QA, Process Engineering, Fluid Dynamics Engineering, Mechanical Engineering, Materials Engineering, Logistics, R&D + Innovation.

E.E: What’s the news for 2021 about new products?

FLUYTEC: We are excited about our close collaboration with Dupont to market Integrated Filtration Products & Systems as part of our strategic partnerships plan for the near future.

In addition, Fluytec continues improving all the existing products towards the achievement of genuine technologies that provide with a significant added value compared to the conventional. Indeed, a new product launch is expected for 2021, however it is still soon to disclose deep details. What we can state is that it will be something related to filtration that will soon become in a game changer in some niche markets.

E.E: What are the ranges of products?

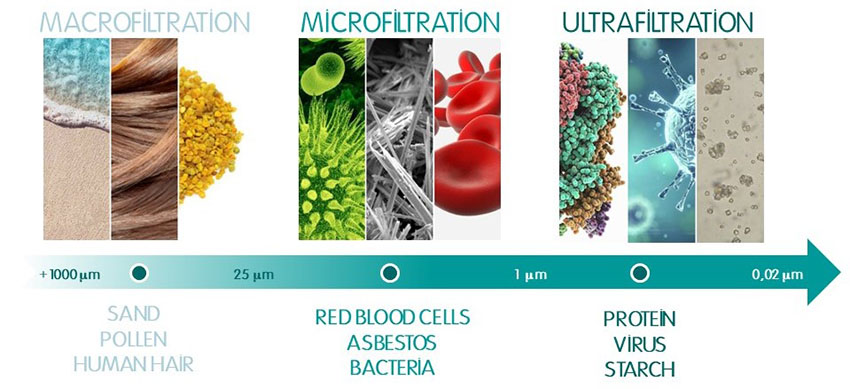

FLUYTEC: The filtration spectrum currently covered by Fluytec can be divided into Macrofiltration, Microfiltration and Ultrafiltration. This depends on the size of the solid particles suspended in the fluids to be handled by our filtration systems, as follows:

There are several materials available for Pressure Vessels (Fiberglass Reinforced Polymers, Stainless Steel of different qualities, Carbon Steel with different coatings/linings, PVC…) and also for the filtering elements, although these are usually PP for most of the projects.

Regarding Ultrapure Water, it is highly remarkable the successful partnership with the Chezc company MEGA, thanks to which Fluytec has started to be well known in the fields of CEDI (Continous Electro-deionization) and EDR (Electrodyalisis Reversal).

Macrofiltration (Removal of Suspended Solids ≥25µm)

Automatic Backwash Self-cleaning Filters:

– Composite Materials (Fiberglass Reinforced Polymers)

– Steel Materials (Carbon Steel and/or Stainless Steel)

Manual Basket Strainers & Bag Filters:

– Composite Materials (Fiberglass Reinforced Polymers)

– Steel Materials (Carbon Steel and/or Stainless Steel)

Microfiltration (Removal of Suspended Solids ≥1µm)

Cartridge Filter Housings:

– Composite Materials (Fiberglass Reinforced Polymers)

– Steel Materials (Carbon Steel and/or Stainless Steel)

– Thermoplastic Materials (Polyvinyl Chloride)

Bag Filters:

– Composite Materials (Fiberglass Reinforced Polymers)

– Steel Materials (Carbon Steel and/or Stainless Steel)

Ultrafiltration (Removal of Suspended Solids ≥0.02µm)

Integrated Ultrafiltration (i-UF) Systems

Continuous Ultrafiltration (c-UF) Systems

Traditional Ultrafiltration (UF) Systems

Ultrapure Water

Continuous Electro-deionization (CEDI) Systems

Electrodialysis reversal (EDR) Systems

Complementary products

Collecting Nozzles for Sand / Multi-media Filters

– Polypropylene

– Steel Materials

Static Mixers

Grooved Pipe Flexible Couplings

E.E: At what stage is the market where you are currently active?

FLUYTEC: The market has already reached significant levels of maturity in the last few years. The global economy recession obviously has had an impact, but being an essential market, it has been hindered limitedly compared to other activities.

E.E: What can you tell us about market trends?

FLUYTEC: Increasing access to clean water, concentration of population in certain cities/areas, industrial development, efficient waste water management… are all drivers for water treatment. In particular, we do believe that Wastewater Reuse and Desalination will have a continuous growth in the next decades, driven by a combination of climate change, environmental standards and social/economic trends.

E.E: What are the most innovative products marketed?

FLUYTEC: It is hard to mention only one product, mainly because every single item in the portfolio is frequently subject to innovative improvements that make them genuine: from our Continuous Ultrafiltration (c-UF) System to our Hydraulicaly powered Self-cleaning Filters (FCP Series), among others. As a proof of fact, Fluytec currently holds several patents and continues working on new ones, a practice that represents a dynamic company philosophy that always attracts new leads and reinforces the customers loyalty.

E.E: What estimations do you have for 2021?

FLUYTEC: Although we do hold a cautious approach to this year’s economic recovery, we ultimately expect the market to recover the previous trends and figures we all had in mind before the pandemic. Therefore, our estimations look forward to close the year with very similar results as we achieved in 2020 and foresee sustained growth in the next 3 years.