ForTest, based in Modena, Italy, manufactures instruments for air leakage and flow rate testing, applicable to all industrial sectors, from automotive to medical. The company has been designing and manufacturing air leak test and flow test equipment for over 25 years. ForTest’s aim has always been not to sell products, but to offer 360º solutions that allow customers to find the definitive remedy to their quality problems. The company, whose main market is Europe, is also present in China, India and the USA, where it achieves 50 percent of its total turnover through its dealers.

Interview with Stefano Coni & Luca Ferrari, Sales Department of ForTest.

Easy Engineerin: What are the main areas of activity of the company?

Stefano Coni & Luca Ferrari: ForTest, for over 25 years, has been designing and manufacturing air leak test and flow test instruments for various application sectors: automotive, biomedical, household appliances, hydraulics, mechanics, etc.

ForTest has continuously innovated with technological solutions of excellence, often ahead of their time, both in the field of technology and services.

From being a supplier of leak testing equipment to end users, ForTest has become an all-round consultant at all stages of the process, from studying the application with the customer, to working alongside automation manufacturers, right up to the metrology.

Metrology, together with the development of the entire traceability part, is today one of the sectors that involves the most resources, with the development of real revolutions such as ForTest Lab (automatic calibration system), the ForTest app for smartphones for remote assistance, the LeakID system (for automatic verification of the testing process via RFID) and the new Dual Absolute technology, which replaces the old differential drop technology, now outdated.

E.E: What’s the news about new products?

Stefano Coni & Luca Ferrari:

Flow testing on surgical mask EN14683

At the beginning of 2020, during the Covid period, ForTest developed an important instrument that measures the degree of respirability of surgical masks, the T9731. The European standard EN14683 (or the American ASTM 2100F) indicates all the characteristics that surgical masks must have, including a breathing characteristic, which is called “differential pressure”. Based on this parameter, the mask can be of different categories (I, II, IR, IIR). The T9731 instrument can automatically test a mask in just a few seconds. The operator only has to press a button, making the test very fast and traceable because the machine records all data via USB pen drive or LAN network.

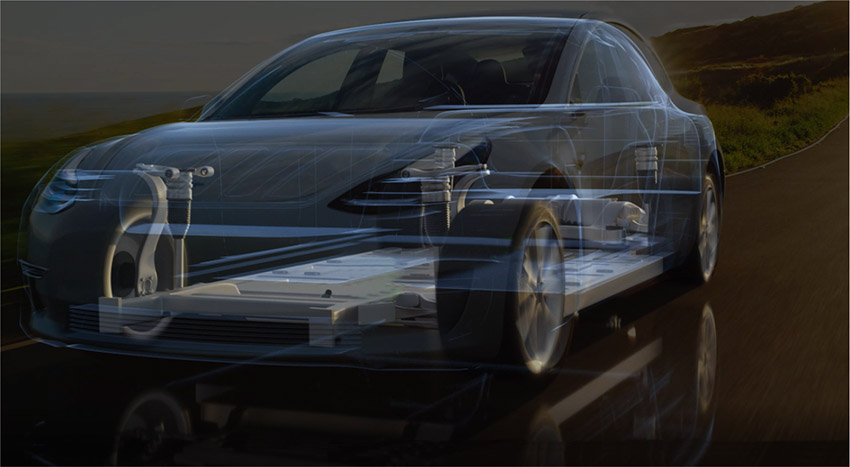

Leak testing for E-Mobility

E-vehicles can range from an electrically assisted bicycle, a fully electric motorbike or scooter, a fully electric car or hybrid vehicle, small electric drones and even large aircraft.

One of the big technical challenges in the production of electric vehicles is ensuring the performance and safety of the large batteries that power them.

ForTest has patented specific solutions for leak testing of battery packs, such as the new Dual Absolute system, which is now ready to replace the outdated differential pressure drop technology.

The use of leak testing in the mass production of electric vehicles is relatively recent, as the transport industry was accustomed to testing internal combustion engines.

The move away from fossil fuels and CO2 emissions has prompted the development of new technologies.

These new devices present new challenges for production line leak testing.

E.E: What are the ranges of products?

Stefano Coni & Luca Ferrari: The most innovative and wide range of industrial leak testing instruments comes from the combination of three distinct performance classes (Series T6000, T8000 and T9000) and four different types of measurements: Absolute Pressure Decay(Txx9x), Differential Pressure Decay (Txx6x), Compliance (Txx8x) and Continuous Leakage Measurement (Txx7x).

- Entry-level equipment: T6990, T6961

- Applications: Valves, Packaging, Medical leak testing, Mechanics, Hydraulics.

- Standard equipment: T8990, T8060, T8970, T8980, T8890

Applications: Automotive, Valves, Hydraulics, Packaging, Medical leak testing, Mechanical, Gas, Pneumatic, Heating, Alternative Energy, Cylinders, Hydraulics, Household Appliances, Electronics.

By leveraging the modularity of the new “T” Series, the flow test is also designed to cover all possible application needs by structuring the range into four types of measurements:

- Continuous micro flow (Tx71x), differential micro flow (Tx72x), continuous flow rate (Tx73x), continuous flow RFO – Real Flow Output (Tx74x).

- Digital flow calibrators: M2710, M2730

- Applications: Industrial, Metrology, Laboratory.

- Standard equipment: T8710, T8730

- Applications: Automotive, Household Appliances, Hydraulics, Packaging, Medical, Mechanical, Gas, Heating, Cylinders, Hydraulics, Electronics.

- High-level equipment: T9710, T9730, T9740

Applications: Aerospace, Alternative Energy, Automotive, Brake Calipers, Cylinders, Electronics, Foundry, Gas, Heating, Household Appliances, Hydraulics, Hydraulics, Mechanical, Medical, Nuclear, Packaging, Pneumatic, Valves.

E.E: At what stage is the market where you are currently active?

Stefano Coni & Luca Ferrari: ForTest works with all major brands application areas may vary from Aerospace, Mechanical, Automotive, Medical, Household Appliances, Oleodynamic, Electronic, Packaging, Foundry, Pneumatical , Gas and Heating.

E.E: What can you tell us about market trends?

Stefano Coni & Luca Ferrari: I the last year, two particular sectors have been highlighted: Automotive linked to Electro-Mobility, and Medical, due to Covid-19 and the need to test products such as surgical masks.

E.E: What are the most innovative products marketed?

Stefano Coni & Luca Ferrari:

- T9731 High Performance Flow Test equipment EN14683

- T9732 High Performance Flow Test equipment EN149

- T8090 Dual Absolute Leak Tester for E-Mobility components

E.E: What estimations do you have for 2022?

Stefano Coni & Luca Ferrari: The aim is to increase total turnover by 15% compared with 2021 and to open new European resellers & partners.