Gamak was found in 1961 to fulfil needs of the Turkish industry for a critical component, the “Electric Motor”. In a very short time, the company accelerated production of the first domestic electric motor in Turkey and became the market leader. Gamak became the alternative and strong supplier of imported motors, which had many disadvantages like cost and spare parts’ sourcing. Their quality has always won recognition and appreciation.

In the last 60 years, Gamak has become one of worldwide major electric motor manufacturers besides Turkey. With a most comprehensive electric motor range from 0,06 kW up to 3000 kW, they meet almost all electric motor requirements of the industry. Being the market leader in electric motors, they have transferred this experience to wind turbine generators. Gamak produces “the first loca” wind turbine generators at 5MW power level since 2018.

Easy Engineering: What are the main areas of activity of the company?

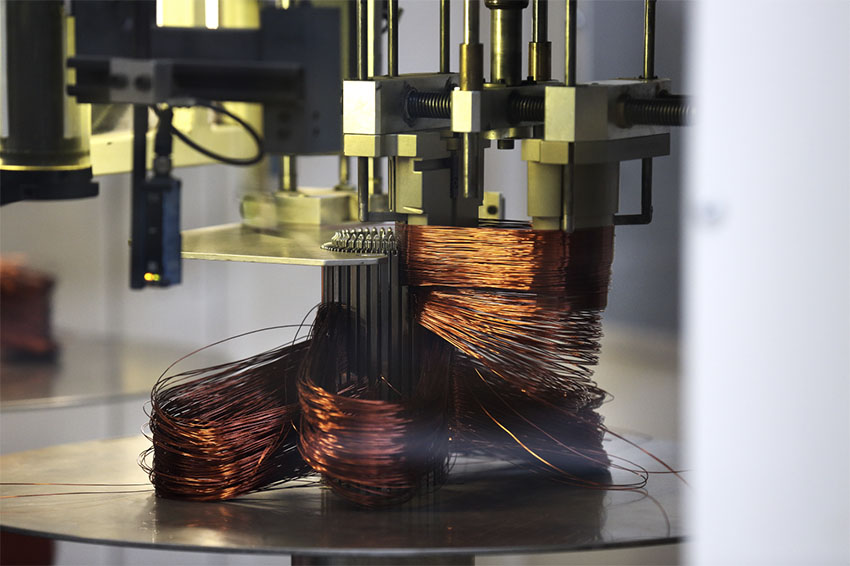

GAMAK: Today, in our 60,000 sqm plant within our 330,000 sqm area, we continue to empower the Turkish industry with our nearly 1.000 employee work force. We produce a wide range of 0,06kW – 3000kW aluminium and cast iron frames. We take our production and quality to the next level with our competent workforce and latest technology production lines. As one of the few electric motor manufacturers in the world producing its own wire, we draw out our wire in 0,2-1,32 mm range. Having one of the best test laboratories in Europe, we guarantee our products meets energy efficiency standards worldwide, IE1 to IE4. As a result of our R&D projects, we not only produce high-efficiency motors (IE3 – IE4), but also create distinctive designs for specific demands. Thanks to this potential, we answer all Customer needs in a dynamic and flexible manner.

Our expertise and experience gained in electric motors made us a strong player in wind turbine generators too. Wind turbines in Turkey are now using the 4 MW power generators produced by Gamak.

E.E: What’s the news for 2021 about new products?

GAMAK: Our R&D activities continue with pace in 2021 too. Our goals in 2021 include widening our range in special application motors. We also have plans to enrich our IE4 premium energy efficiency motors which offers great opportunities for energy savings across markets and applications.

E.E: What are the ranges of products?

GAMAK: We have the capacity to produce 1 million motors annually with power capacities ranging from 0.06 to 3000 kW and frames ranging from 56 to 630. We take our production and quality to the next level with our competent workforce and state-of-the-art machinery.

E.E: At what stage is the market where you are currently active?

GAMAK: Turkey is a mature market, following EU regulations and IE3 efficiency is mandatory from July 2021 on. At GAMAK, we do not just settle for leadership in the domestic market but also work to increase our global market share. We export our European-standard motors (IE3) to over four dozen countries in almost every corner of the world, particularly in the EMEA region. We rank among the top 10 companies exporting electric motors to the EMEA region. In addition to our cutting-edge high efficiency motors, we also continue to produce and export IE1 – IE2 motors, which are preferred particularly in the Middle East and Africa. Thanks to the mobility we get from manufacturing all motor parts in our own factory, we can adapt our machinery to ensure that our production meets the standards required by various regions. This gives us a great advantage in meeting all export demands and allows us to stand out in the market.

E.E: What can you tell us about market trends?

GAMAK: Electric motor market is expected to grow at a CAGR of over 7-8% during the forecast period of 2020 – 2025. Factors such as rising environmental concerns and increasing demand for electrical energy are expected to be major drivers driving the market. The increasing demand for electrical energy to sustain global development requires consistent heavy investments in power supply generation. This has helped the market for electric motors grow significantly in recent and is expected to do so in forecast period. Electric motor applications make up approximately 40% of global energy demand, 65-70% in industry.

The globally increasing demand for energy-efficient, operationally optimized drives gave rise to a range of different regulations for determining efficiency. It was only in 2008 that the international standard IEC 60034-30 globally regulated the efficiency classes and legal requirements placed upon the energy efficiency of low-voltage three-phase motors in a uniform manner. Now, we are evolving into IE3 and IE4 efficiency induction motors everywhere.

E.E: What are the most innovative products marketed?

GAMAK: In 2016, we introduced smoke extraction motors to market and got the series certified. In 2018 our 5 MW wind turbine generator serial production started. In 2019, ExProof motors in 71-250 frame sizes were placed on market.

E.E: What estimations do you have for 2021?

GAMAK: The industry is driven by rising electrification, mechanisation and automation of the industrial processes. Rising urbanisation, industrialisation and electrification in emerging economies like China and India is providing further impetus. With an increasing focus on motor energy conservation and environmental protection, the demand for energy saving high-efficiency motors have been growing. We think that despite the coronovirus affect, electric motor market will continue to grow, especially in energy efficient motors.