Gatemaster Offshore is a consulting, design and engineering company aimed at providing reliable gate, hatch, and access door hardware for offshore use.

As specialists in offshore gate and hatch hardware, Gatemaster Offshore understands the challenges faced by engineers when designing offshore platform access systems. Ensuring the safety of operators working on the platform, adhering to stringent material specifications for offshore use and the need for products with maximum longevity are key considerations.

From initial design scope to final manufacture and delivery of the offshore gate and hatch hardware, the company’s products are engineered to the highest standards to fulfil clients’ project aspirations.

Interview with Jacob Napthine, Commercial Manager at Gatemaster Offshore.

Easy Engineering: What are the main areas of activity of the company?

Jacob Napthine: Our story starts on land, where we develop and manufacture gate locks and gate hardware for the domestic and industrial gate industry, an industry we’ve been in since the early 1990’s. During this time, we have become specialists in this area with our renowned lock ranges and gate accessories. We’ve always had research and development in-house and with it comes a natural innovative spirit aimed at proactively developing products to make gate installations easier and simpler for the manufacturers.

In 2015, we were faced with our first offshore gate project as the designers for the Dudgeon wind farm asked us to supply a rising hinge for the gates. With our onshore expertise in gate hardware and engineering, we took on the challenge and evaluated the full scope of the project to best utilise our knowledge and apply it to offshore use. Developing a bespoke hinge for that project became the beginning of our offshore ventures.

And we haven’t slowed down since. After the Dudgeon hinge, we have worked on several other offshore gate projects of which some were further adaptations of that first hinge, and others completely new and bespoke products. Our mission is to highlight the importance of offshore gate, hatch, and access door hardware and to provide reliable solutions that are not only effective but will continue to perform for a long time. We continue this mission by ensuring our products are engineered to stand up to the unyielding offshore surroundings.

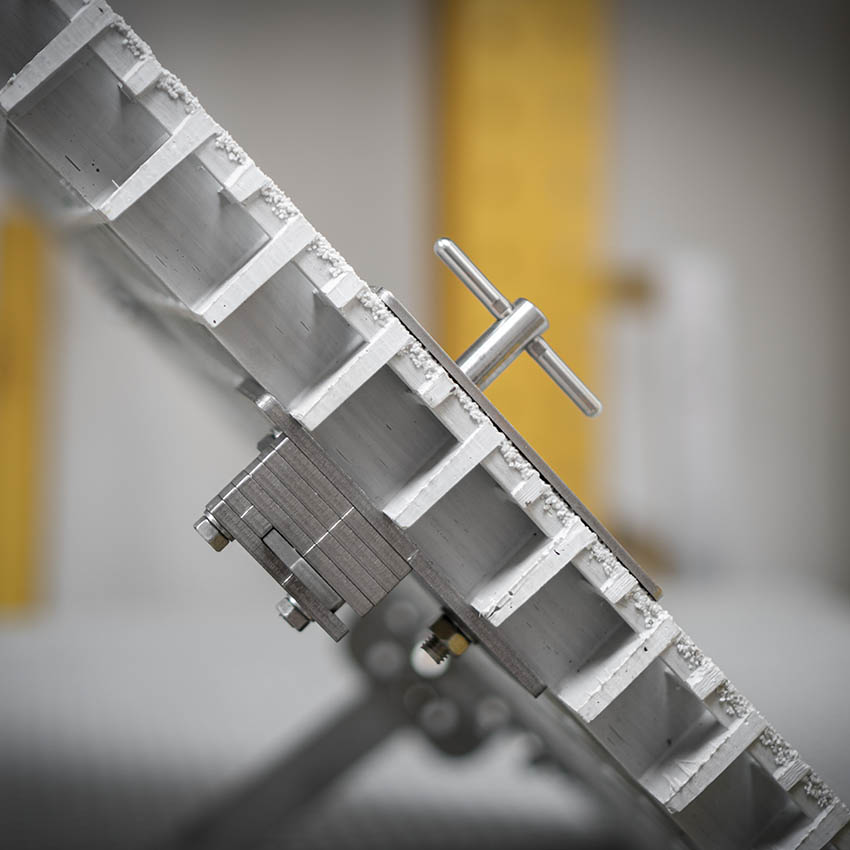

Now, we get involved early in the process with consulting and giving advice on the best hardware for offshore projects. But we are engineers at heart and the main bulk of our work is focused on designing the solutions and using our engineering expertise to solve the challenge ahead. Once the design is completed and tested properly, our clients will approve to go ahead with production. All our products are manufactured and assembled at our factory on the South Coast of England using up-to-date CNC machinery and lean methodology to ensure that the highest quality is achieved.

E.E: What’s the news about new products?

J.N: When we first started with gate hardware for offshore applications, we used our existing gate hardware knowledge and adjusted it to work in the highly corrosive environment. Since then, we have developed new and innovative solutions for new projects with different requirements.

Our products are therefore constantly being reviewed and with each new project, we come up with new ways of solving the offshore challenges.

We have an exciting new spring-assisted gate closing hinge, which we are looking forward to announcing soon. At this stage we are finalising patents and NDAs linked to the product, so keep an eye out for the imminent launch.

E.E: What are the ranges of products?

J.N: We offer any type of hardware for offshore gates and hatches. This includes self-closing hinges, gate stays and catches, hatch accessories, and locks.

E.E: What can you tell us about market trends?

J.N: We specialise in heavy-duty, reliable, and long-lasting products as opposed to the current status quo which is using existing hardware solutions that have been designed for onshore use. Just because something is stainless steel doesn’t mean it is suitable for offshore use. We are working on educating the industry and showing how big difference choosing the right gate hardware can make. It might be a small component in the grand scheme of installing and building a new wind farm park, but in the long run, getting these components right at the beginning will mean less time spent on O&M. If a gate hinge breaks, it will be a high safety risk for anyone onboard. It might even mean no personnel can go on the platform. It can lead to wasted man hours and funds due to having to shut down operations while it is being replaced.

We are glad to say that learnings and word of mouth from previous successful projects is starting to expand throughout the industry. We are fortunate to have been specified on large projects such as Dogger Bank Phase A and B, Dudgeon, Beatrice to name a few.

E.E: What are the most innovative products marketed?

J.N: Our newest product, which is yet to be announced due to NDAs and patent pending. This will offer a unique way of gaining access to the platforms thanks to the access mechanism. We will have more on this later this year, so keep an eye out for any announcements!

E.E: What estimations do you have for 2023?

J.N: We are expecting a great result for 2023. We have a wide range of projects on the go – both large and smaller scale, national and international. As a UK-based company we are fortunate to be in a position to help manufacturers, designers, and energy companies around the world, promoting the benefits of our British quality engineered products.