GDM is a worldwide leader in the Hygiene Disposable industry, committed to provide innovative converting and packaging solutions, both stand-alone and turnkey, for the manufacturing of baby open diapers, baby pants, adult incontinence briefs and protective underwear and lady sanitary napkins.

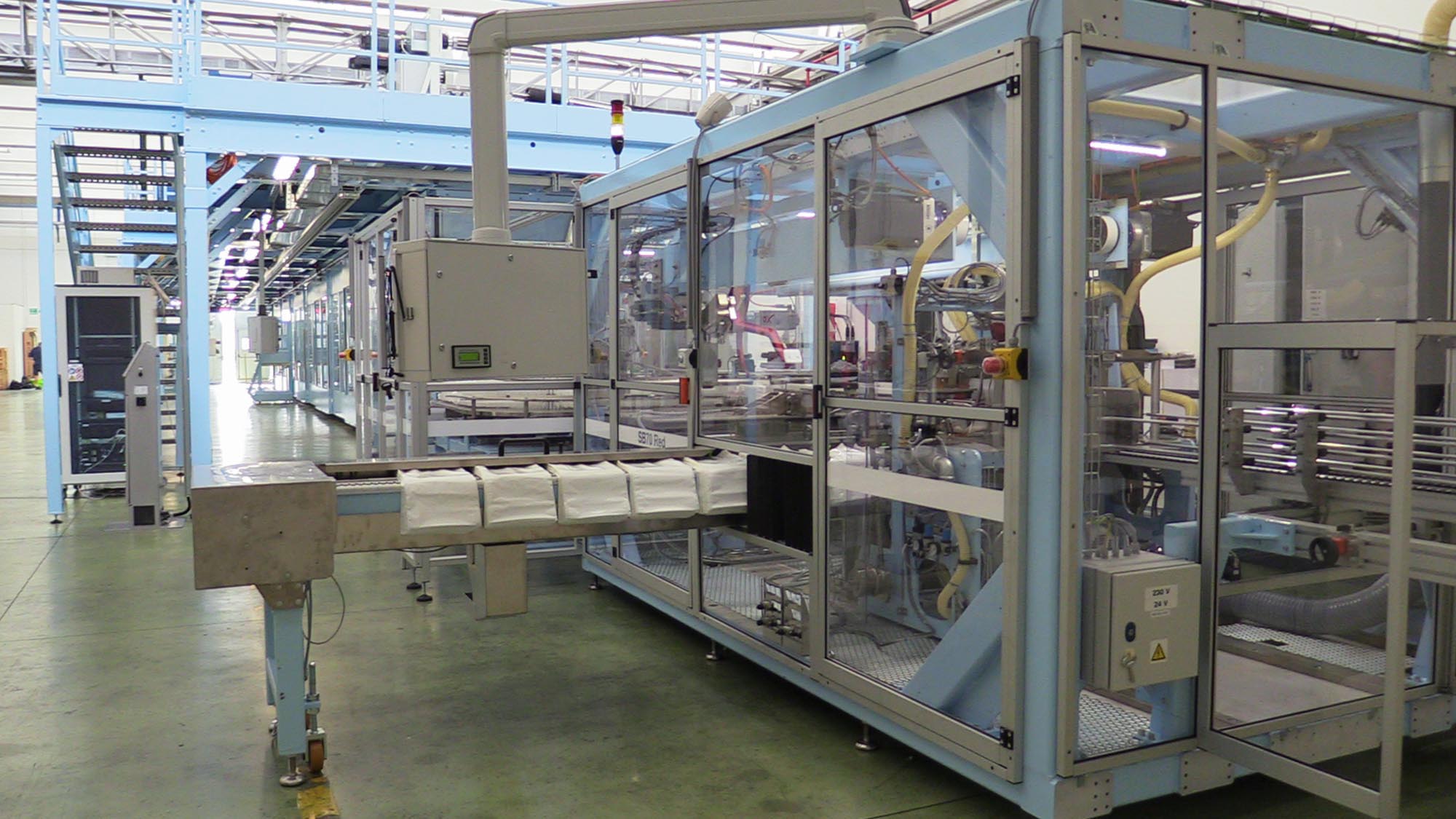

As part of Coesia Group, GDM covers the complete range of the production process, from raw materials handling to End of Line.

Interview with Maurizio Cantoni, Head of Sales and Marketing at GDM.

Easy Engineering: What are the ranges of products?

Maurizio Cantoni: In the baby segment and with specific reference to medium-high speed manufacturing machines, GDM offers effective solutions responding to flexibility and production performance requirements. B6-W and B8-W are baby open diapers lines delivering performing products minimizing raw material costs through the Front & Rear Wing Zero Waste application. Considering high speed lines, B-12-W and B10-W are GDM’s best in class baby open diaper lines, producing up to 1200 ppm with high efficiency and reliability.

GDM boasts a Baby Pants platform, covering different production capacities from 600 ppm to 900 ppm, respectively with our BP6 and BP9. They have been designed for product quality and flexibility in terms of sizes, costs optimization and ease-of-use.

Concerning the adult segment, in addition to our A5-MR, designed to manufacture high quality adult open products with rectangular panels at a speed up to 500 ppm, we have developed an Adult Protective Underwear platform, featuring AP3 and AP5 machines with production capacity respectively up to 300 and 500 ppm. AP3 offers extreme flexibility: different Core formation options, Extra Thin Core, core wrapped, pre-made engineered core, wider range of raw materials to use, optimized side seam welding and quick size change by means of E-cams. AP5 offers not only flexibility, but also high performances through the Welding Wheel for a quick size and product change.

As for lady segment, we propose a machine platform designed to manufacture a product with a premade or made in line core, with or without wings, single wrapped in normal, long and overnight sizes, at the speed of up to 1200 ppm using a wide range of raw materials.

As regards packaging solutions, we can offer a wide range of models able to run up to maximum 100 package/min with an input product speed of up to 1000 ppm which, in connection with our converting lines, allow to get the best Total Cost of Ownership results.

Process Know-How and Innovation is GDM Customer Service way to support our customers in daily production needs through Value Added Solutions: Original Spare Parts and spare parts stock service, Maintenance services, Equipment modernization & Customized upgrades, Structured Training Programs & Interactive Documentation, Consultancy Services for OEE improvement, Production Support Services and First Aid help line 7/7 available.

E.E: What’s the news about new products?

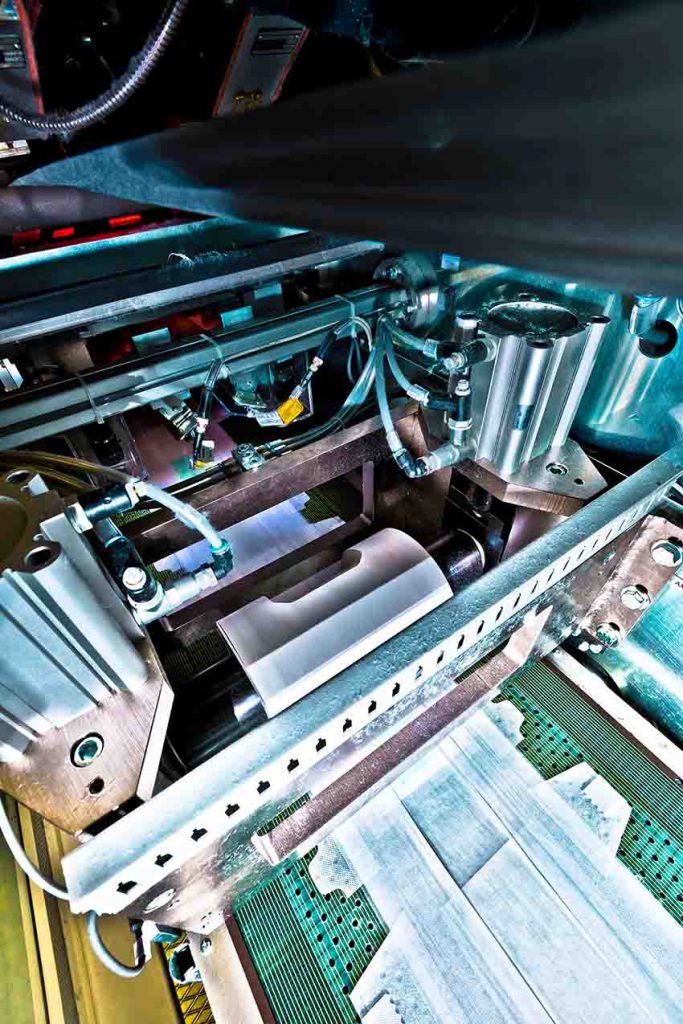

M.C: Matching baby diapers market’s trends and needs, requiring performing products at the lowest operating costs, GDM has studied the ultimate generation of core – Extra Thin Core – also featuring permanent channels. It ensures high absorption, low acquisition time and low rewet. Thanks to the improved recipe stability, minimizing product weight variation, and the best possible mix of fluff and SAP of more than 70%, this solution allows to save up to 800 k€ raw materials per year and installed power up to 30% with reference to a baby machine at 600 ppm.

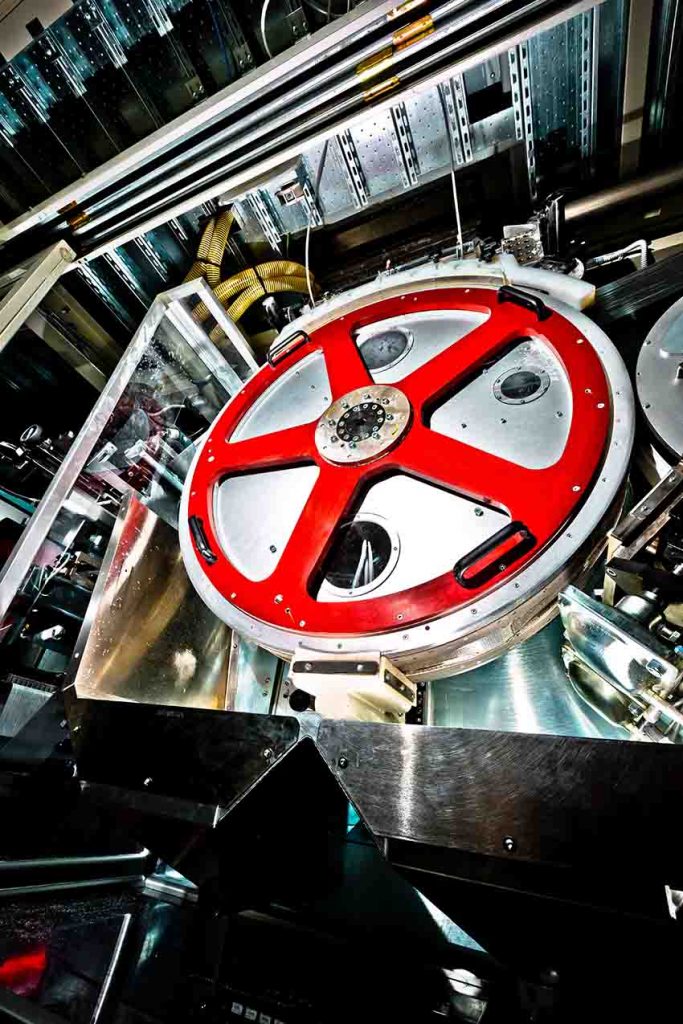

Pants platform machines can be equipped with our flexible solution, “Welding Wheel”, able to generate a side seam welding in baby and adult pant type product.

This GDM patented technology enables to produce an extended number of sizes with the same unit and zero time size change.

We are proposing an enhanced new digital portfolio of services that help our customers from AI and IoT up to AR. For instance: OptiMate, the Coesia and GDM’s machine interface with connectivity and smart functions, allowing easy access to innovative digital services and remote support while increasing OEE and simplifying operations. PerforMate, through its user-friendly personalized dashboard, employs machine learning algorithms to provide a bird’s-eye view of the production line – or the complete fleet of your lines – with asset monitoring, loss tree analysis, trending and alarm notifications, aggregated outlook and, last but not least, the chance to access advanced consultancy services in direct connection with our Control Room experts. Enhanced Remote Assistance, to maximize equipment uptime through faster, leaner and better troubleshooting.

E.E: What can you tell us about market trends?

M.C: In 2015-2020, the adult incontinence segment has grown the most within the hygiene industry due to rising living standards, improved consumer awareness and greater product variety. Speaking of purchasing power, most of it will come from people aged 40 to 44. This group already represents 10% of the global average gross income and will become the biggest by size over the next ten years.

The baby segment is, to a certain extent, stable. Yet, when we take value and volumes into account, it definitely is the strongest one. A main driver of the baby market is millennials. They differ a great deal from older generations, as they are tech-savvy, green-conscious, information-hungry and in want of premium products that offer mass personalization.

Femcare is on the rise due to lower social stigma and higher living standards, especially in emerging markets like India, Indonesia, Nigeria and Vietnam.

Speaking of age groups, millennials and Gen Z are a force to be reckoned with. Sustainability is a mounting concern for millennials and Gen Z, most of which are willing to pay more for environmentally friendly products.

With millennials and Gen Z entering the market, disposable hygiene has been reshaped into two macro-categories: affordable premium and super premium. As a result, many players in the market have modernized their offer to meet these preferences.

Affordable premium has quickly become a magnet for DTC (direct-to-consumer) brands and private labels. This is a new prominent category, defined as intermediate between affordable and what was once described as premium. In baby hygiene, affordable premium brands feature elements such as colorful design, joyful packaging, bundles, home delivery, money back guarantee, plant-based ingredients and cause marketing. In the adult market, claims like leak-free, superior absorbency, high-performance, skin-safe, 100% breathable materials and eco-conscious are common, together with a stronger focus on wellness and body-positivity.

E.E: What estimations do you have for 2022?

M.C: In recent times, the manufacturing machinery industry has undergone a profound reorganization of its digital strategy. Several factors are behind this: an increase in competition across the board, combined with a global trend towards premiumization, has pushed market players in the field into investing more and more in research and development.

To fulfil the evolving needs of the market and satisfy such diverse expectations, the manufacturing machinery industry is going through a Industry 4.0 strategy encompassing hardware, software and services, where concepts such as smart manufacturing, data analysis, and Internet of Things become central.

This is not just a restyling. On the contrary, it is a through and through rethinking of entire manufacturing’s business model, head to toe, with far reaching implications on its value chain. So, we expect that all these topics will be a focus on 2022.