For the past 20 years, Godrej & Boyce, the parent company of Godrej Lawkim Motors, has offered specialized electric motors to major compressor manufacturers in India having been pioneers in Hermetic Motors segment in India. Later the business activities in motors were expanded to components of motors and specialized motors for industrial and commercial applications. Besides this, calibration services are offered to various industry clients in the mechanical, thermal, electrotechnical, fluid flow, and optical disciplines.

Godrej Family took over Lawkim Ltd in 1977 and then this family-owned company amalgamated into Godrej and Boyce Mfg Co Ltd as one of the 14 divisions of Godrej and Boyce in 2008, but the Lawkim Brand still stands apart for its products and services. Since then, the company has consistently met the demands of customers around the world because of their reliable processes and high standards for quality. Out of the total strength of blue and white-collared employees of around 1000 people, one hundred seasoned engineers work as a highly competent team at Godrej lean production plant.

Today, Godrej’s cutting-edge production facility in Shirwal, India, close to Pune, effectively serves their clientele on a global scale.

Interview with Xercsis Marker, Executive Vice President & Business Head, Godrej Lawkim Motors.

Easy Engineering: What are the main areas of activity of the business?

Xercsis Marker: We provide Calibration Services to numerous engineering industrial verticals. The quality of production is directly impacted by the control settings on equipment that this service helps firms ensure and optimize. In order to meet the increasing expectations of our clients, we developed five NABL Accredited calibration facilities in Mumbai, Pune, Vadodara, Gurugram, and Chennai and satellite offices in Bangalore, Hyderabad, Visakhapatnam and Bhopal and a unique offering of Mobile Calibration van to serve the customer at their doorstep.

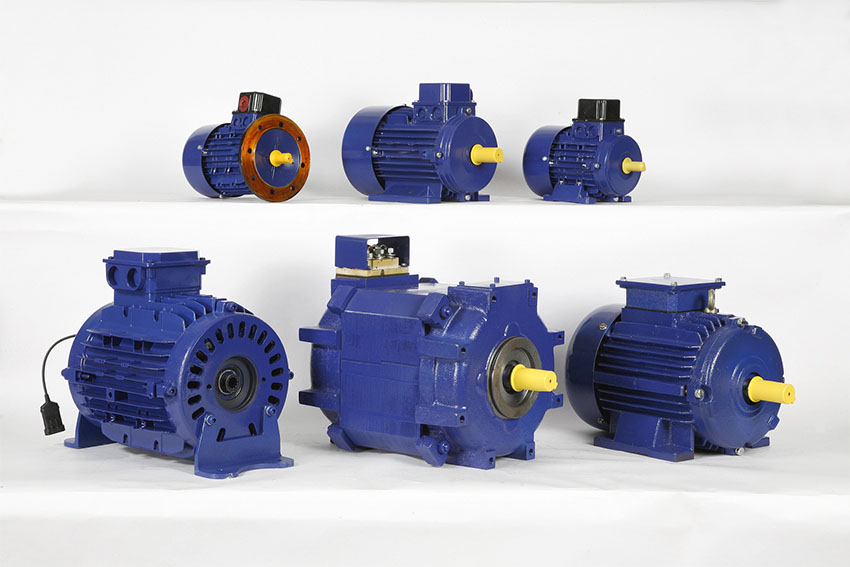

We make high-quality, efficient hermetic compressor motors that can be customized for every need of the appliance industry and manufacturing plants. We provide customized solutions for the design and manufacturing of a wide range of motors, from single-phase to three-phase motors in IEC frames, with a capacity to manufacture 4 million motors every year. We are also one of the leading electric motor lamination manufacturers, suppliers, and exporters of laminations for motors, which are available in different grades of electrical steel and have carved out a niche of their own in the market.

E.E: What’s the news about new products?

X.M: This year we will be coming up with the following Motors, many of which are joint development programs with discerning OEM Customers:

- Semi-hermetic Motor Range for commercial cooling and Chillers up to 100 HP.

- Specialized Motors for Sewage Pump of IP68 capability

- New series of Motors for linear actuators

- Special BLDC Motor and Intelligent Controller for cooling application

- Specialized Motor for off-Highway EV

- EV motor for small carriage application

- Range expansion for EV retrofit Motors

- Special Motor components for Commercial cooling

- Anechoic Chamber calibration

- EMI EMC Calibration

- Mobile Van for Automobile / Aerospace customers

- Automated Calibration for Electro-Technical Equipments

- Medical Device Analysers

- Automotive Transient Generators calibration for E-Vehicle application.

E.E: What are the ranges of products?

X.M: Godrej Lawkim Motors is an industry leader in producing Hermetic Compressor Motors, Specialty Motors, and Motor Components like Stators, Rotors, Die-Cast, and Laminations. Our highly effective motors are constructed from premium materials that adhere to strict international production standards. As the inventors of hermetic motors, we draw on our years of experience and broad engineering knowledge to provide our clients with energy-efficient solutions for a variety of applications, including commercial, industrial, and residential appliances.

We offer all types of calibration services for all industries. Our goal is to offer a differentiated experience at the doorstep of our premium customers.

E.E: At what stage is the market where you are currently active?

X.M: We are market leaders for the hermetic compressor motor addressable market in India, which includes all hermetic compressor motors that compressor manufacturers across the country outsource. Domestic refrigerator hermetic motors currently hold a market share of roughly 47%, followed by air conditioner hermetic at 20% and commercial refrigeration hermetic at 90%.

Despite not directly exporting, MarketWatch lists us as one of the top 10 independent hermetic motor firms worldwide. We solely sell to compressor manufacturers, and they in turn export the compressors that have our motors on them. Based on the current arrangement’s success in the southern states and our market analysis, we see excellent potential in other areas (Maharashtra and Delhi). This will be repeated in Gujarat after careful consideration.

Moreover, we also offer Calibration services to our customers. Last year, we launched the mobile calibration van that houses a range of calibration instruments and equipment as per the customer’s requirement. It offers up to 20 services on the go which includes dimension calibration. Our calibration van has been conceptualized and fabricated by Godrej Storage Solutions, another business of G&B and a leading player in building special solutions for mobile service stations.

E.E: What can you tell us about market trends?

X.M: With the advent of new generation Intelligent Motors for numerous applications, Godrej Lawkim Motors has upgraded technology in several segments. The future’s increasingly stringent energy standards are met by a new series of ultra-efficient BLDC motors for domestic refrigerators and business refrigeration such as Visi coolers, Chest freezers, etc. In order to replace the current PSC Motors in air conditioners, BLDC fan motors offer advantages including plug-and-play flexibility, which lowers operating energy costs for the end-user. Special industrial motors with copper die-cast rotors increase the effectiveness of the motors. A new line of motors for off-highway vehicles and e-vehicle retrofits are being promoted to encourage ecologically friendly vehicles with a low total cost of ownership. Specialized Motors, which include linear actuators and various motion profiles with controls specialization, can be utilized for specialized machinery.

Introduction of new manufacturing products using IoT and Green technology and several such newer technologies is anticipated in the near future where precision calibration is required.

Xercsis Marker, Executive Vice President & Business Head at Godrej Lawkim Motors

E.E: What are the most innovative products marketed?

X.M: We have recently launched E-Switch technology for general purpose motors. The classical centrifugal switch requires multiple moving parts for different types of motors and polarity whereas, the new e-switch technology in motors, requires a single device, is pre-programmed and easy to maintain. The new e-switch technology provides long life, and strong reliability and hence proves to be a long-term asset for the consumers. The electronic switch by Godrej Lawkim Motors is also environmentally friendly, RoHS compatible and does not contain any hazardous material such as Silver Cadmium contacts.

Digitally signed certificates for calibration services through the online portal for all the customers is another unique proposition offered by us.

E.E: What estimations do you have for 2022?

X.M: For this financial year 2023, we are targeting:

- 30 million USD from New Products and services

- Total revenue of 100 million USD.

- Addition of two global customers each for motors in the US and Europe markets and two customers in the middle east for calibration services to enable our target of exports business to progress to 20% of the total Revenue of the division by FY25

- Profitability to improve year on year by at least 1% point with higher ROCEs

We as a division will be constantly striving to align, execute and achieve our business goals aligned to the new Purpose, Vision, Mission and values that have been finalized recently in the completion of 125 years of our existence.