GOEKELER is a medium-sized high-tech company in the field of metrology based in Lenningen, at the foot of the Swabian Alb near Stuttgart. The family-run company now in its second generation. Since 1984, with the beginnings of 3D coordinate measurement technology, the company has been delivering styli to measurement machine manufacturers and their end users around the world.

Interview with Patrick Häußler, Global Sales Marketing Manager at GOEKELER Messtechnik GmbH.

Easy Engineering: What are the main areas of activity of the company?

Patrick Häußler: We supply the original equipment for your measurement machines, as well as standard styli and special styli solutions. Due to the unique process depth on offer at our Baden-Württemberg site, we are able to deliver special solutions to customers worldwide in rapid time. In Addition to the production of special styli we also deliver our Surface-Roughness-Contour products and our ICT artefacts around the world.

E.E: What’s the news about new products?

P.H: Not direct on a product – on a full technology!

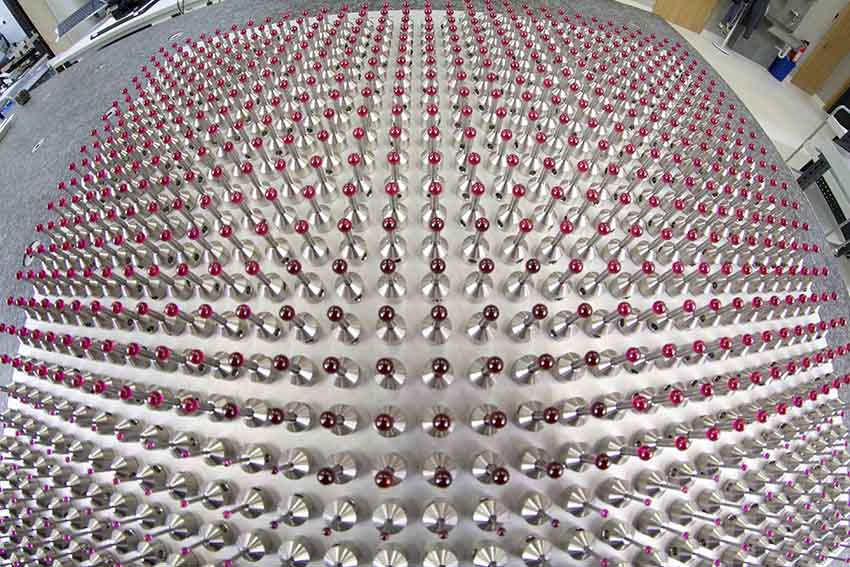

GOEKELER is currently the only manufacturer in the world to produce its complete range using the latest connection technology. This connection technology by vacuum brazing ensures maximum strength of the ball on the shaft.

The vacuum brazing process will certainly become a standard in the field of probes in the next few years. At GOEKELER already today.

E.E: What are the ranges of products?

P.H:

- Special styli in every kind of configuration

- Standard styli for tactile measurements on a Coordinate Measuring Machine (CMM)

- Standard accessories for CMM like extensions, cubes, adapters and tools

- Calibration artefacts and parts for comparative measurements on a computer tomograph

- Styli for Surface-, Roughness-, and Contourmeasrurements (FOK styli)

- Machine Tool Styli for manufacturing machines (MTS)

- Equipment and Services

- We also sell original manufacturer parts like Zeiss adapter plates or accessories for other machines.

- The portfolio is rounded off by our repair service for FOK styli.

E.E: At what stage is the market where you are currently active?

P.H: I think the metrology industry as such is on a stable growth course.

Product quality and the respective referencing capabilities will continue to increase and as a result reliable measurement technology is needed worldwide. The field of optical metrology is growing fastest, and this has been observed for years.

E.E: What can you tell us about market trends?

P.H: As I told above the field of optical metrology is the fastest growing and trending sector. But currently there are still limits to this trend and a tactile machine is also still needed. I think some kind of multi-sensor technology will be used permanently.

The trend of moving the measuring technology into the production line and away from the conventional measuring room is also recognizable.

E.E: What are the most innovative products marketed?

P.H: Our most innovative products are the full portfolio which we produce with our vacuum brazing technology. Currently GOEKELER is the only manufacturer in the world which applies this 100% to all products.

E.E: What estimations do you have for 2022?

P.H: We are looking very confidently to 2022. We are planning firmly for the control trade fair in May. This would finally be the industry meeting point again after 2 cancelled years. I also assume that the entire industry including GOEKELER will continue an upward trend.