GPAINNOVA is a multinational company that was founded in Barcelona, Spain in 2013. It currently has two regional sales subsidiaries, including GPAINNOVA America in Florida, USA, and GPAINNOVA Asia in Shenzhen, China. One of the company’s main missions is to provide cost-efficient, environmentally friendly, and time saving technologies to various industries. The company’s primary focus is in metal surface finishing with their DLyte and Murua electropolishing systems. They also have their GPA SEABOTS line dedicated to marine mapping and preservation. When the COVID-19 pandemic began, the company shifted its production to create the RESPIRA ventilator, to help aid hospitals and save lives.

Easy Engineering: What are the main areas of activity of the company?

GPAINNVOVA: GPAINNVOVA is present in several industries. Its main area is the metal surface finishing industry, with the machines DLyte and MURUA. It is known to be a global leader and a key player in surface finishing, by disrupting the traditional liquid electropolishing process with the introduction of the DryLyte technology in 2016, the first and only Dry electropolishing system in the world. The DLyte brand is our primary focus in the company. We offer a variety of machines depending on the needs and production size of the customer. Overall, we have served over 400 customers worldwide within in the dental, healthcare, aeronautics, automotive, industrial, and jewellery industry.

Our other main product is the MURUA which it is designed for goldsmiths in the Jewellery sector. We also have a range of machines for gold, silver, and brass alloys, that is a grinding and polishing system in one automated step. Similar to the DLyte, it is able to polish parts that can’t be accessed mechanically, the surface material is not affected, and it preserves the geometry of the piece. Our MURUA machines save money, require low maintenance, and don’t use any environmentally harmful materials.

Our subsidiary GPA SEABOTS, which began in 2019, producing USV’s (Unmanned Surface Vehicles) in the marine electronics market, has become another main activity for GPAINNOVA, which helps cities create bathymetric studies, and helps with marine preservation.

Finally, there is our line of RESPIRA ventilators manufactured to help with the shortage of emergency equipment during the current pandemic.

E.E: What’s the news for 2020 about new products?

GPAINNVOVA: During Q4 of 2019, we launched the DLyte Pro500 which is designed for finishing large batches and heavy workpieces in the healthcare, aeronautics, industrial, and automotive industries. It provides a faster and more efficient surface finish than any other machine. It was fully introduced to the market in 2020, and during the year, we have installed multiple machines in Europe and Asia with great success. We had to speed up production due to the large demand.

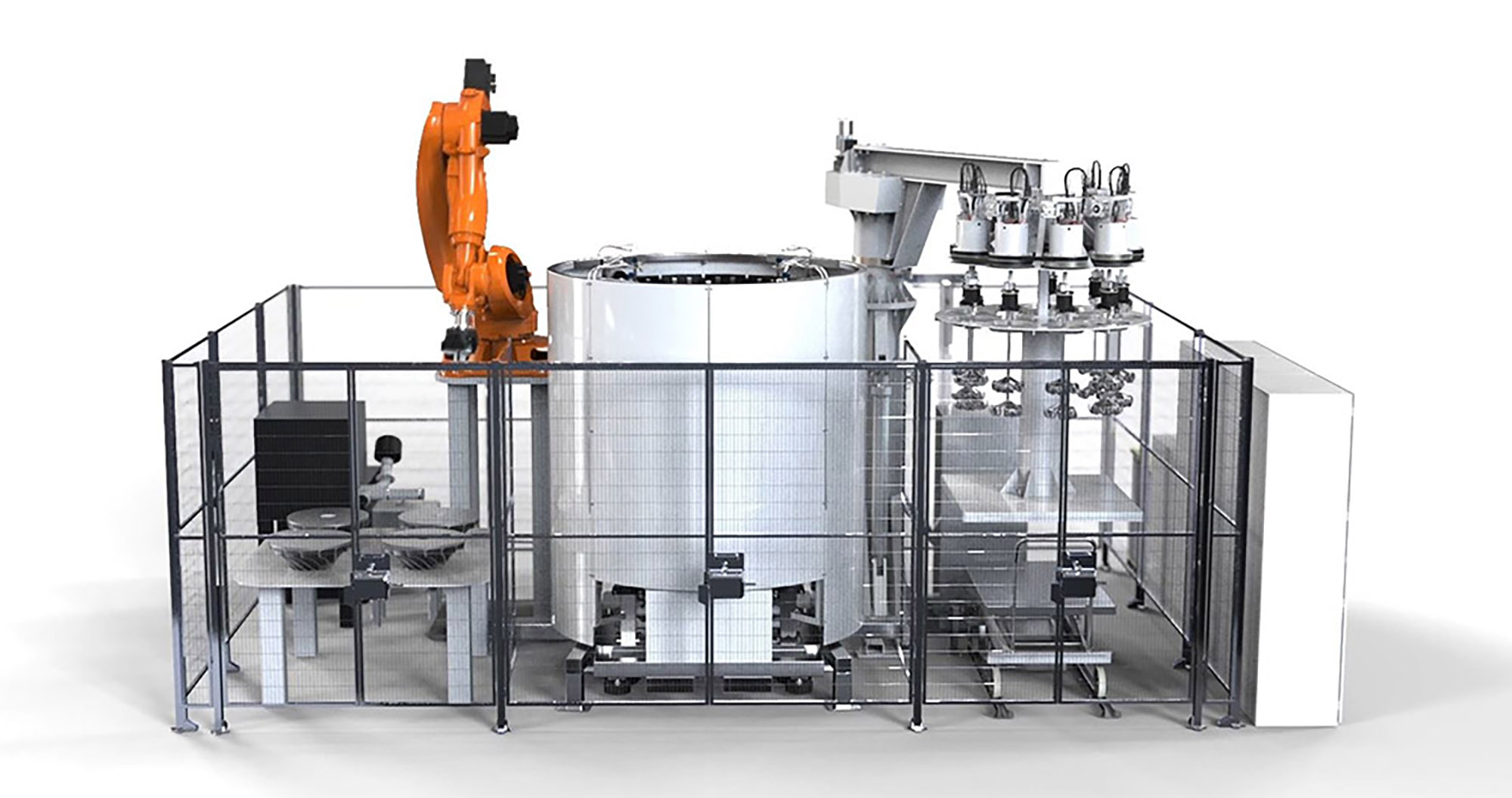

This year we also launched the DLyte 10.000 which is our biggest machine for modular solutions. It is also used in the healthcare, aeronautics, industrial, and automotive industries. Unlike other DLyte machines, the DLyte 10.000 has a crane for mass production which can polish hundreds of pieces simultaneously (200 pieces up to 50x50x50mm). The parts are attached to 4 holders, each with a maximum volume Ø 450 mm, and 650 mm height. It also has a robot for complex and large geometries (1 piece up to 750x500x500mm).

Lastly, due to the impact of COVID-19, we developed our latest project called the RESPIRA Device, the first high-performance invasive ventilator based on the automation of a manual resuscitation device. It has been designed to work continuously and intensively. It has different ventilation modes, giving it great versatility to treat patients in different phases of invasive ventilation.

It was produced in a record time of two weeks with the Siemens Digital Industries as the main partner and its providers SMC, TEG, and MAM. It was also developed together with Hospital Clinic de Barcelona, and the Germans Trias i Pujol hospital, following all the guidelines of the Spanish Agency for Medicines and Health Products of the Ministry of Health.

(The RESPIRA device is still pending on the CE certification and it is not destined for the EU market, or placed in service until it meets the EU requirements).

E.E: What are the ranges of traded products?

GPAINNVOVA: DLyte, MURUA, RESPIRA Device, and GPASEABOTS.

E.E: At what stage is the market where you are currently active?

GPAINNVOVA: Our main market where we provide our machines is the metal surface finishing market, specifically the dry electropolishing systems which are a growing market due to the demand worldwide and its importance in the supply chain. The introduction of additive manufacturing for metal 3D printing has made the electropolishing market grow.

The global medical ventilator market where we have our RESPIRA device, is expected to grow due to the demand needed as a response to COVID-19 with a growing CAGR of more than 5%. We believe the long-term ventilators are a huge impact on the market growth.

The marine electronics market where GPASEABOTS has its products is also in a growth stage since sustainability and marine preservation efforts and marine preservation has become a priority to many companies, cities and governments.

E.E: What can you tell us about market trends?

GPAINNVOVA: All the markets our products and projects are featured in are in a growing stage. One of our main missions is to being a pioneer in producing more disruptive and effective solutions in the various industries we are in. Many of the market trends in which our products are present are growing due to technological and environmental changes, as well as in response to COVID-19.

One of the main trends that makes the electropolishing market grow is the growth in Additive Manufacturing solutions as well as healthcare applications. We have seen a growth in demand of our DLyte machines because of the many benefits our DryLyte Technology offers, compared to traditional liquid electropolishing. Our system helps achieve a better surface finishing by offering a more homogeneous result, increasing corrosion resistance, preserving the geometry of the pieces, and being a biocompatible solution in a faster and more environmentally friendly process.

The marine electronic market where GPASEABOTS offers USV’s has a growing CAGR of more than 3% due to the technological innovations and the change in consumers and governments in finding marine preservation solutions.

E.E: What are the most innovative products marketed?

GPAINNVOVA: As previously mentioned, our most innovative products are in different industries, which that’s what makes GPAINNOVA a disruptive company.

The most innovative product and the most successful one is the DLyte machine, which uses our patented DryLyte Technology, the first and only dry electropolishing system. The applications for DLyte finishing technology range from grinding, rounding and deburring to surface smoothing and high gloss polishing of aesthetic parts. We offer different ranges from small compact series machines to mass production and modular solution machines. Many of the benefits that it offers compared to traditional liquid electropolishing are corrosion resistance, fatigue resistance, resistance to erosion and premature aging, excellent biocompatibility, and improved adherence of subsequent coatings. All of this is achieved in a more environmentally friendly way while reducing the number of processes and therefore the total polishing time.

Our other innovative products are created by our subsidiary GPASEABOTS. They specialize in floating technology for exploration and preservation of the aquatic environment. They have a range of USV’s (Unmanned Surface Vehicles) that offer a wide range of applications such as cartography and bathymetric surveys, inspections, environmental studies, search and rescue, as well as the advertising and sporting events. In addition, one of our other products is a semi-submerged buoy that captures microplastics that are present in the water, and can be used to analyse them in the lab.

Lastly, our latest innovative product is the RESPIRA device, built as a response to the health crisis caused by COVID-19. It is the first high-performance invasive ventilator based on the automation of a manual resuscitation device. It has different ventilation modes, and it is designed to work intensively without interruption.

E.E: What estimations do you have for 2020?

GPAINNVOVA: The estimations we have for this current year are:

- DLyte: 11 million €

- MURUA: 100,000 €

- RESPIRA Device: 2,2 million €

- GPASEABOTS: 400,000 €