The German company Greif-Velox Maschinenfabrik sets the standard for packaging machines across the globe and is on the way to becoming the sector’s leader in technology. Right now, Greif-Velox Maschinenfabrik GmbH has more than 150 specialists working in 89 countries around the world. In 2020, it launched a North American subsidiary in Sacramento, California.

Easy Engineering: What are the main areas of activity of the company?

GREIF-VELOX: We devise and produce innovative bagging machines and filling systems, with a constant focus on achieving maximum efficiency for our customers. With a sharp focus on customer needs, the company is continuously developing new systems and patents to find sustainable solutions to the sector’s long-standing problems. With a company history spanning almost 1,000 years, Greif-Velox has continuously exhibited the company’s three values: efficiency, innovation and reliability. Furthermore, we are becoming more internationally focused and – via the global network of trading partners and service organizations – even closer to our customers.

E.E: What’s the news for 2021 about new products?

GREIF-VELOX: This year, Greif-Velox has already introduced three new, innovative products to the market. The Greif-Velox VeloVac-FIBC is the world’s first machine to offer dust-free and contamination-free bagging of extra lightweight powders. Bagging particle sizes of less than 200 micrometers and a bulk density of 10 to 450 grams per litre was previously only possible in valve bags using Greif-Velox’s VeloVac vacuum system. Following a worldwide trend, we responded to our customers’ increasing demand for larger containers with the VeloVac-FIBC.

Additionally, Greif-Velox also enhanced ValvoDetect, an optical measurement system that detects the main causes of defectively sealed bags and separates them out before bags are filled or palletized. This allows quality control costs to be reduced. With fewer complaints, the customers’ brand will be strengthened.

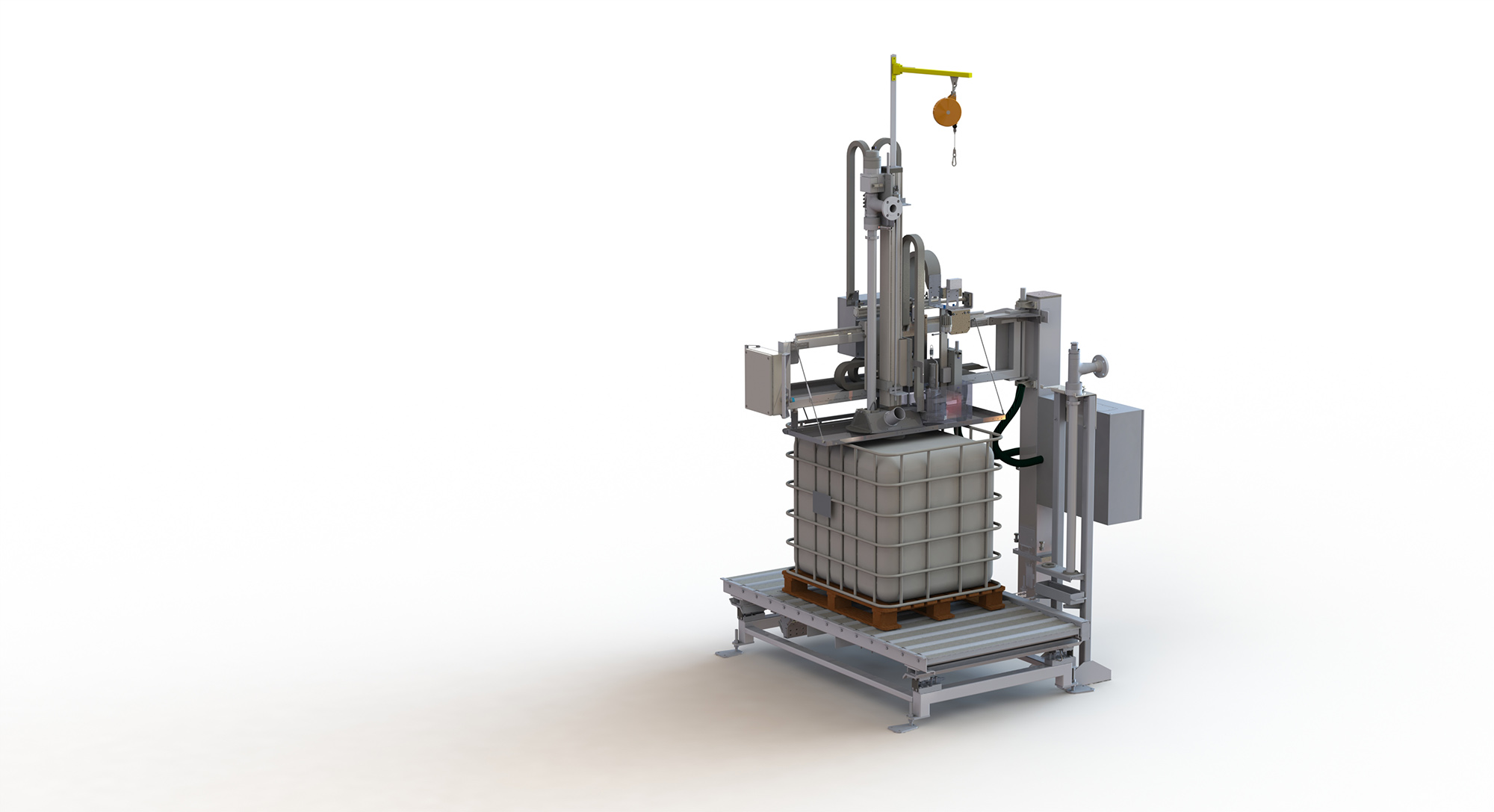

Finally, we introduced A-DOS-C, the world’s only fully automated IBC filling and sealing system. Its innovative two-in-one closing tool guarantees correctly closed lids by measuring and documenting both screw-in depth and torque. This guarantees a high level of process reliability: The containers are perfectly sealed so that no product can escape during transport. As a result, the complaint costs due to incorrectly closed IBCs can be significantly reduced and customer satisfaction is likely to increase.

E.E: What are the ranges of products?

GREIF-VELOX: Greif-Velox offers the right technical solution when it comes to the safe and efficient filling of food, chemicals or petrochemicals. We provide customized concepts and developments – from integrating new features into existing systems to installing fully automated, full-line solutions for powder, liquid or solid materials. Furthermore, all of our systems can be retrofitted with updated equipment and technology in order to continuously improve their overall functionalities.

E.E: At what stage is the market where you are currently active?

GREIF-VELOX: Especially in Europe and the U.S., our markets are recovering fast. You can observe a positive trend particularly in the chemical industry where companies are starting to invest again. Investments in the food sector are still a bit behind and many projects have not been resumed yet. Across all sectors around the world, we feel the impact of the current shortage on semi-conductors and building materials since the Covid-19 pandemic has put enormous pressure on supply chains.

E.E: What can you tell us about market trends?

GREIF-VELOX: Currently, one of the strongest drivers for our markets is electro mobility. Due to the rising demand for batteries in this sector, there is also a rising demand for its components, e.g. carbon black. This triggers huge short-term investments in one of our key industries, the vacuum bagging of extra lightweight powders.

The market also demands larger sizes of containers for both liquids and solids. We see a trend that more IBC/ FIBCs are requested instead of barrels or valve bags. In the silica market, for example, the customers of our customers ask more frequently for FIBCs instead of bags and silo trucks. As a reaction to this trend, we developed the aforementioned Greif-Velox VeloVac-FIBC.

E.E: What are the most innovative products marketed?

GREIF-VELOX: The VeloVac-FIBC is our most innovative product as the first of its kind worldwide that can cleanly and safely bag the finest powders into FIBCs. Equally innovative is the development process that gave rise to this new product. An interdisciplinary, “design for excellence” team from Greif-Velox optimized the design of the classic VeloVac system – from operation to digital system integration to transport, everything is ideally designed for the use of big bags.

E.E: What estimations do you have for 2021?

GREIF-VELOX: 2021 will be challenging, but ultimately a successful year. Business in the food and chemical sector will recover fast and investments that were not made during the pandemic crisis will be made now, as current numbers already show.

Of course, the lead times increase when everybody starts investing at the same time; so in light of the current shortage on certain materials such as semi-conductors, the challenge becomes even bigger. But we look ahead with optimism.