Greyparrot was founded in 2019 to create a world where every piece of waste is valued as a resource.

The company uses AI-powered computer visions systems to monitor, audit and sort waste flows at scale. Their platform provides waste data and insights to some of the world’s largest waste management organizations, covering two thirds of Europe as well as facilities in Peru, Egypt, South Korea and India.

Waste managers, producers and regulators use those analytics to send less valuable material to landfill, and improve accountability throughout the waste value chain. Greyparrot is currently on track to divert 30,000 tones of waste from landfill by 2023 — a stepping stone to our ambitious goal of reducing emissions by 119 MTCO2e per year by 2030.

Easy Engineering: What are the main areas of activity of the company?

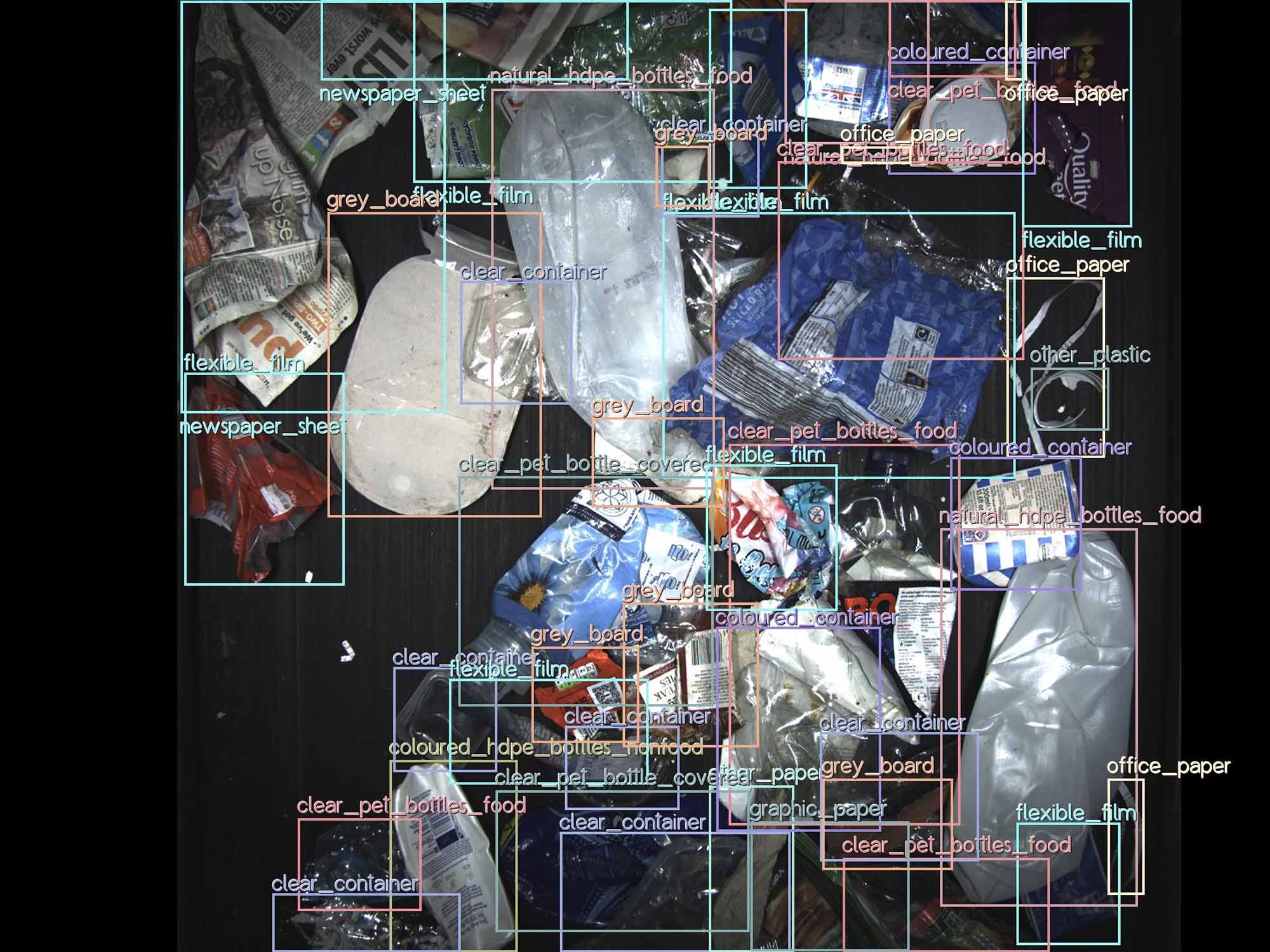

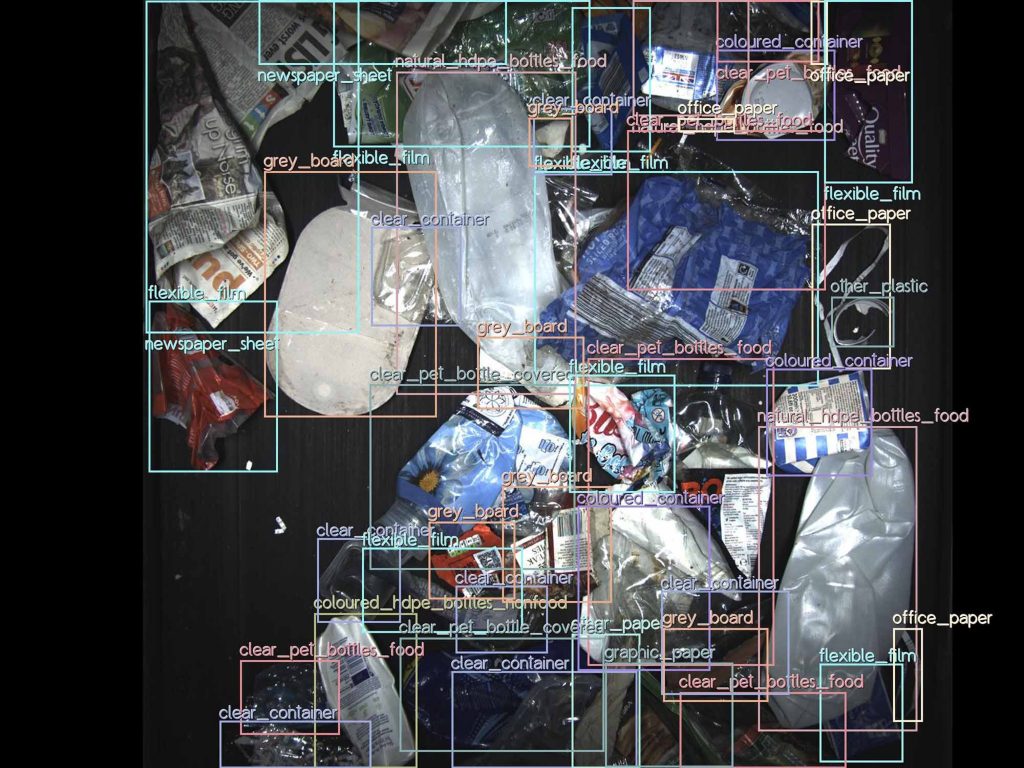

GREYPARROT: Greyparrot monitoring units use computer vision to track waste objects at material recovery facilities (MRFs). They’re powered by cutting-edge AI, which is constantly evolving with the help of our engineers and deep learning experts. It can currently recognize over 50 material types with 95% accuracy, and will be able to identify over 100 in the coming months.

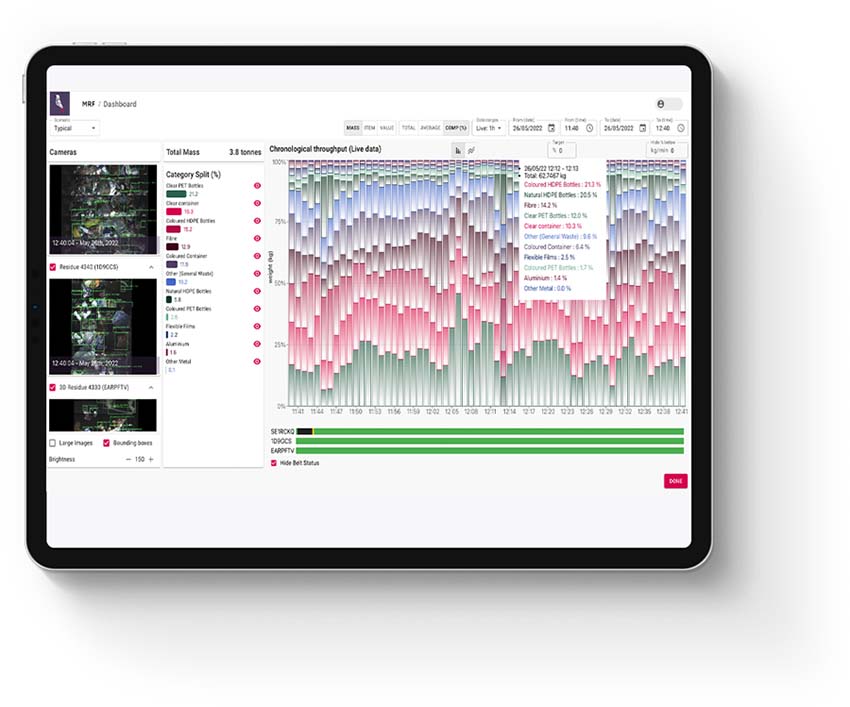

The data our units collect from conveyor belts is transferred to an analytics dashboard in real-time. Waste managers at companies like Suez, Biffa and Veolia use it to maximize their recycling rates, product quality — and revenue — by making proactive adjustments.

Our data isn’t restricted to the Greyparrot platform. We use APIs to integrate with third-party sorting machinery and software, allowing the industry to embed AI intelligence in existing infrastructure.

E.E: What’s the news about new products?

GREYPARROT: Aside from expanding the number of materials our AI can recognize, our deep learning team has also developed brand recognition. Next year, we’ll introduce the ability to track waste objects according to their brand and stock-keeping unit (e.g. a 330ml bottle of Diet Coke).

It’s a complex and exciting challenge for our engineers, who are at the forefront of digitization in a traditionally-analog industry. With the introduction of Extended Producer Responsibility (EPR) across the UK and EU, our brand data will be the driving force behind policy implementation.

To that end, our engineers are working with an AI consortium established by PepsiCo — shaping the future of recyclable product design.

E.E: What are the ranges of products?

GREYPARROT: Our core product is the customizable Greyparrot Waste Analytics Dashboard. It organizes and analyses the data that our AI-powered monitoring units gather from MRF conveyor belts. Data is presented in real-time, and can be filtered by mass, material type or financial value.

We also offer an AI Vision Integration. Our open API connects Greyparrot with sorting robotics and third-party software.

E.E: At what stage is the market where you are currently active?

GREYPARROT: From SUEZ to Viridor and Veolia, some of the waste industry’s leading players have already deployed AI in active MRFs.

These high-profile early adopters have paved the way for widespread adoption. Competition, as well as regulatory, labor and consumer pressure have encouraged the rest of the industry to embrace artificial intelligence. Widespread adoption is likely to take place in the next year.

E.E: What can you tell us about market trends?

GREYPARROT: Waste management is at a massive turning point. As we collectively work towards a circular economy, it’s clear that there’s still the need to ‘close the loop’ by reusing more valuable material.

Recycling rates aren’t high enough, and everyone from regulators to brands have realised that we don’t know enough about waste. Consumers are now educated and suspicious of ‘greenwashing.’ The waste management industry is now at the heart of the circular economy discussion, and will guide everything from policy to product design in the coming months and years.

For evidence, look no further than EPR, plastic taxes and brand commitments to improve recyclability and reduce their reliance on virgin materials. To enact any of those changes in a provable way, we need data — and a digitised waste sector.

E.E: What are the most innovative products marketed?

GREYPARROT: AI-powered robotics are at the forefront of innovation in the waste sector. The integration of sophisticated sorting machinery with accurate and comprehensive AI recognition will likely transform the operations of individual MRFs.

Intelligent machinery is just one side of the coin, though. We’ve taken the trend a step further by opening AI’s ‘black box’, and making the data used by robotic arms available to waste professionals through our dashboard. Industry-level change can only take place if stakeholders across the value chain gain a better understanding of the products they design, produce, dispose of, regulate, recycle and reuse.

The most innovate product currently available to the waste sector is the data and insight it has just gained access to.

E.E: What estimations do you have for the rest of 2022?

GREYPARROT: The remainder of 2022 will see the majority of the waste industry continue to acclimatize to — and learn about — AI.

Alongside industry education, the measurable success of AI in major recovery facilities will pave the way for widespread adoption in 2023. As regulations come into effect and brand sustainability commitments are assessed, the waste sector will need more data than ever.

By the end of next year, the technology will have evolved from disruptor to industry standard.