Guidetti Recycling Systems – leading manufacturer in the field of metals’ recycling – represents ‘Made in Italy’ in the world, with the know-how acquired in more than thirty years of experience and investments in research and development. Guidetti’s passion, technology, attention for every functional detail, research of new solutions and development of systems aimed to excellence.

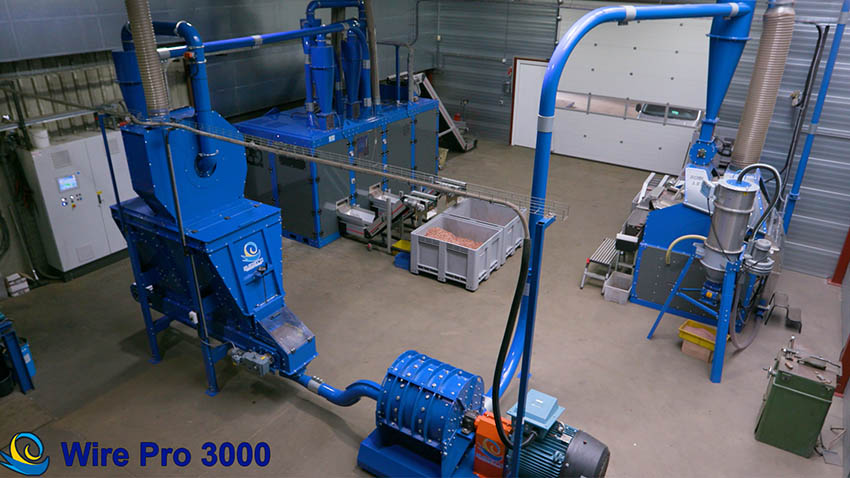

The company designs compact machines and lines for the recycling of non-ferrous metals and materials – aluminum, nickel, lead, copper, zinc – through reduction size and dry- separation systems, to safeguard the raw material and make it available to be used.

Guidetti’s story begins in the mid-80s in a small building in Renazzo, near Cento, where Mauro Guidetti manufactured his first prototype, a unique machine, able to separate plastic from cables. The Guidetti global success begins with the conquest of European markets, Japan, Russia, Korea and USA.

Today, the company has 50 different models, 600 filed samples, 5000 plants sold all over the world and a yearly turnover of 13.000,00 euro.

Recycling allows tons of raw materials to be marketed again, saving energy and resources. Profit achieved in terms of reducing raw material consumption, costs for citizens and CO2 emissions.

Easy Engineering: What are the main areas of activity of the company?

GUIDETTI: The main areas are recycling metals from scraps such as electric cables, e-waste, residues after shredded cars, and in every field where is present metals that can be recovered.

E.E: What’s the news for 2021 about new products?

GUIDETTI: 2021 is the year of completion of the MRP project in the context of HORIZON 2020 of the European Union. This new system provides for grinding without the aid of lame, 2 plants have been built 1 in our factory in Renazzo Italia, available to perform tests with interested customers, and one at a customer who uses continuously to test its effective validity.

But we are also designing new methods of recycling electric and electronic cables with an innovative system currently not present in the metal recycling market, which we will patent.

E.E: What are the ranges of products?

GUIDETTI: Our range of products consists of 2 types:

- Compact machines for the recycling of electric cables called Sincro composed of a granulator and separator in a single monoblock starting from 65 kg / h of cable to be recycled, which grind and perfectly separate the copper (or aluminum) from the plastic which can be add a pre-shredder from the PMG series, the largest in the series, recycles up to 1 ton / h of wires.

- Complete lines for the recycling of electronic waste (WEEE), Car Fluff, radiators, electric motors, etc.

E.E: At what stage is the market where you are currently active?

GUIDETTI: The recycling market in the non-ferrous metals sector is growing strongly and we position ourselves at a medium-high level, because the quality of our machines is very high, even the expectations of our customers. There is still a lot of space in the market, thanks also to the attention that is being focused both on the circular economy, and on the environment.

E.E: What can you tell us about market trends?

GUIDETTI: The market trend denotes a great demand for raw materials, an increase in metal prices and delays in supplies, all this due to various conjectures that turn into enormous opportunities for the metal recycling sector, enhancing industrial waste.

For us, 2021 began with an increase in requests for machines for the recycling of electrical cables.

E.E: What are the most innovative products marketed?

GUIDETTI: We have done numerous tests with e-waste electronic waste, with our MRP recycling tower (multi product recycling) so we feel that the need for lines for this type of recycling increases, but the most requested systems are always Sincro machines for recycling of cables, also given the very high price of copper.

E.E: What estimations do you have for 2021?

GUIDETTI: The estimates for 2021 foresee the recovery of the 2020 gap due to the pandemic, returning to the turnover of over 13,000,000 that we had planned for last year. this increase in turnover will be obtained with the sale of medium-small systems for the recycling of electrical cables, the Sincro series.