HAHN Automation is a global operating special machine manufacturer and develops innovative solutions for the automation of assembly and testing processes. Through many years of experience, innovative developments and high quality awareness HAHN Automation has developed into a worldwide leading mechanical engineering company. With own production sites in China, Germany, Great Britain, Croatia, Mexico, Austria, Czech Republic and the USA, HAHN Automation currently employs more than 800 people at 11 locations. Well-known customers in the automotive, consumer goods, electronics and healthcare industries benefit from HAHN Automation’s competence and automation know-how, which has grown since 1992.

Easy Engineering: What are the main areas of activity of the company?

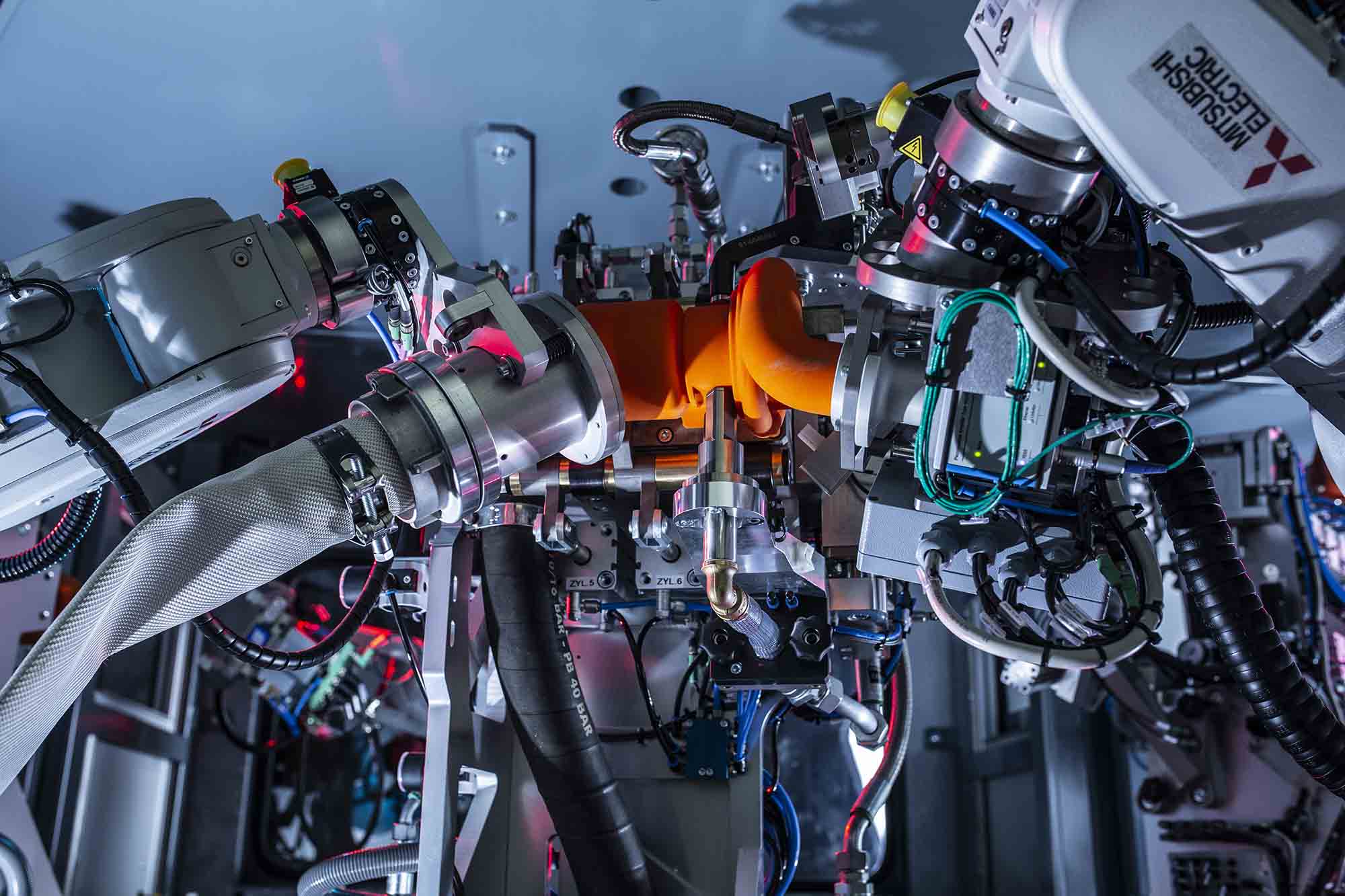

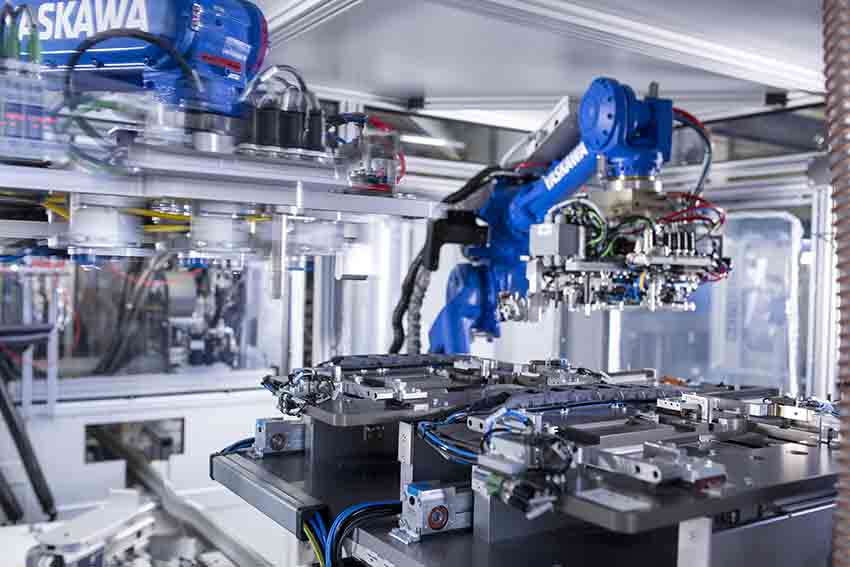

HAHN Automation: Our focus is to build special machines mainly for the automotive healthcare, electronics and consumer goods industry. We are specialized in assembly and testing systems for the processing of all kinds of components such as shock absorbers, electric motors, turbo systems and displays.

E.E: What’s the news for 2020 about new products?

HAHN Automation: In 2020, we launched our first standard product SmartSolutions on the market in addition to large assembly systems in the multi-digit million range. The new SmartSolutions product portfolio offers manufacturing companies a new way to automate processes efficiently, starting with a quantity of one. HAHN Automation’s industrial machining systems map a variety of processes and are easy to operate through every user. Thanks to the software innovation SIA (smart intuitive automation), users can set up and operate the system on a tablet using symbols and graphics. The user interface design is very intuitive due to its design similar to smart phones, keeping the entry barrier for operators low.

E.E: What are the ranges of traded products?

HAHN Automation: Our product range extends from manual workstations and intuitively operated SmartSolutions automation cells around €40k to complex assembly and testing lines in the double-digit million range and a size of several hundred square meters.

E.E: At what stage is the market where you are currently active?

HAHN Automation: In a normal situation we could say that, though we operate in a quite competitive market, it is full of opportunities where we provide innovative solutions to our customers. Taking the automotive industry as an example, the rise of alternative engines and electrified systems leads to new generations of components, and consequently new automated production machines that we develop and install. Of course, this does not come without its own challenges for car manufacturers and their suppliers, but it is still an exciting time to contribute to such developments.

E.E: What can you tell us about market trends?

HAHN Automation: In terms of trends of course we are somewhat bound to orient along the developments of our customers. Here we can name the electrification of devices and components as a trend that has high impact on our business. We also like to look left and right from our core industries to find chances to enter high potential markets. This way we can diversify, while also amplifying our technological knowledge at the same time.

The automation industry in itself also shows some ongoing trends. A lot of those are broadly covered by buzz words like Industry 4.0 and the Internet of Things. For us this specifically means that we have put special focus on our HAHN Digital brand, which provides applications for improved machine performance, monitoring, and Augmented Reality supported remote service.

Lastly one trend that was already strong before and now has become even more relevant due to Covid-19 is the proximity to our customers. From the opening of our first international location, we always aimed to build up fully local expertise starting with engineering across local machine building all the way to on-site commissioning and service. Today we can say that this approach allows us to successfully complete international and cross-continental projects, regardless of current travel restrictions and with the lowest possible risk to our employees.

E.E: What are the most innovative products marketed?

HAHN Automation: As every machine we deliver is a unique design specifically tailored to the customers’ requirements, we don’t really have any catalogue products in our traditional business. Therefore, we rather focus on certain process expertise and industries. In terms of innovation we are leading experts in the dynamic performance testing of automotive components such as turbochargers, shock absorbers, and pump systems. With our partners we are currently developing an EV battery test system.

As our hub for innovation in the medical field, we just opened a new production location in the southern medical cluster of Germany. Here we focus on products like surgical laparoscopic devices.

As mentioned before, in 2020 we also launched the SmartSolutions as our first complete standard product. The real innovation here is that we offer professional automated production equipment at a very low entry barrier. All controls are done on a regular tablet touchscreen, with ease of use as the key idea behind the design. This way the user can benefit of high-end tools and monitored process accuracy, but without any expert knowledge required to set up the machine. This concept is a real novelty in our industry.

E.E: What estimations do you have for 2020?

HAHN Automation: Without doubt, in the coming year the automation industry will still be largely dominated by the developments around Covid-19. Evaluating the actual healthcare situation should be left to the experts, but economically we can already observe impacts of the lockdown. For now, our estimates for the future are more conservative. Currently there is a lot of uncertainty and although everyone is hoping for a swift economic recovery, we have to simulate a continued downturn as well.

While this is our take on the overall industry, we as HAHN Automation remain performing. Various competitors do not have our effective cost structure and have had to reduce their capacity or even close their doors. Our customers buy less in current times; however, they buy more from us as they gravitate to our global presence and our financial strength that the backing by the RSBG gives us.

Furthermore, our experience has allowed us to win new contracts in the medical industry, where we will increase the production capacity for much needed diagnostic equipment.

Our strong global network gives us a solid foundation for the future and despite the issues our economy has been facing, we committed on largely expanding our facilities at our headquarter with a new building close to doubling our footprint. This step was taken in full confidence that we have the tools necessary to navigate through any potential development.

HAHN AUTOMATION

Email: marketing@hahnautomation.com

Site: www.hahnautomation.com