Halstrup-Walcher GmbH is a medium-sized, family-owned company based in Kirchzarten, Germany, in the Black Forest region. About 180 people are currently working at Halstrup-Walcher. The company is known as a professional partner in the field of drive technology, positioning technology, pressure measurement technology, and for calibration and development services. Their customers include many well-known companies all over the world, across a wide range of industries and applications.

Halstrup-Walcher’s partners appreciate their dedication to quality, punctuality, and lean production. In addition to standardized products, they also manufacture customized solutions. With more than 75 years of experience, Halstrup-Walcher represents a reliable supplier for international mechanical engineers. The company still produces 100% of their products in Germany, taking advantage of direct communication between our internal departments – their development departments include electronics and construction experts, and provide an outstanding depth of production expertise. This is a success driver especially Halstrup-Walcher’s engineering projects for individual customer requirements.

Easy Engineering: What are the main areas of activity of the company?

Halstrup-Walcher: Our main industries and applications in the field of drive technology are woodworking machines, bottling plants, and packaging machines. We deliver positioning systems that allow for automated format adjustments in the production machines, significantly reducing setup times for our customers. In the field of measurement technology, we provide high-class solutions in the area of mini environments, overpressure in cleanrooms, filter monitoring and blood pressure devices. We specialize in pressure measurement technology for smallest pressure differences in non-aggressive gases.

E.E: What is the news about new products?

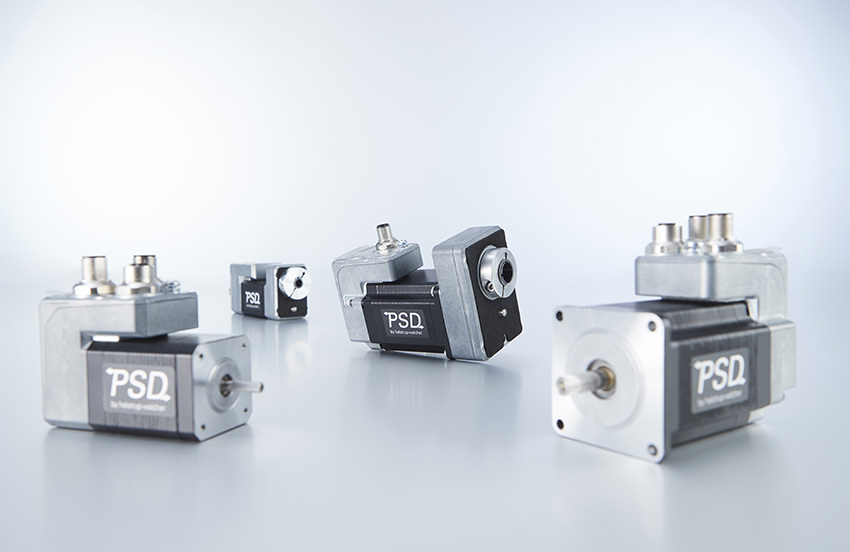

Halstrup-Walcher: We recently launched a direct positioning system, called PSD, with Industrial Ethernet interfaces. Triggered by a specific customer request, we developed a suitable product combining popular features but in a system without battery, resulting in a significantly more compact design. With the new PROFINET interface, our small direct drive systems are now able to operate with a Siemens PLC.

E.E: What are the ranges of products?

Halstrup-Walcher: We are producing drive technology as well as measurement technologies. With our drive technologies, we provide positioning systems in various shapes and with 10 different interfaces. Thanks to our module-based product concepts, hundreds of variants can be realized by halstrup-walcher, allowing our customers to find the best solution for their application. For our measurement technology, we produce differential pressure transmitters and absolute pressure transmitters. For each of those products it is possible to generate customized solutions. Suitable equipment for our products can be obtained in-house.

E.E: At what stage is the market where you are currently active?

Halstrup-Walcher: Automation in production processes is still important in our industries, and will continuously drive engineering projects for the next years. Besides developing new, automated machines, we also have many projects where customers want to increase efficiency of existing machines. There is still a lot of improvement potential in plants, and in close cooperation with our partners, our products help to lever this potential over the next years. Further, when a customer is searching for a reliable measurement system, we are entering the direct planning project of a clean room, for example – which also is a growing market.

E.E: What can you tell us about market trends?

Halstrup-Walcher: In many fairs in both, the international and regional area, present topics include automation, robotic, connectivity, and IoT. When we started producing the positioning systems for the automatic format changeover in 1996, we only had few big machine builders as our customers because the market was not yet ready for process automation. This changed dramatically over the last 10-15 years, and today almost every machine builder has some automatic machines in its portfolio or strives to increase automation.

E.E: What are the most innovative products marketed?

Halstrup-Walcher: In contrast to formally used direct plug connections, innovative products are using IO-Link communication that enable high quality information exchange with less wiring/cables. In the market of drive and measurement technologies, there are several innovative product features leading to more efficient and profitable applications. Our product family of direct drives includes powerful products in a really compact design, which allows for usage in robotics or other moving applications. We focus on developing products that are long-lasting, small and easy to integrate.

E.E: What estimations do you have for 2023?

Halstrup-Walcher: For the year 2023, we are estimating a continuous increase of automation requests. Our products get more and more efficient, and deliver a significant value to our customers. In addition, the overall request on drive technology will continue to increase over the next years, especially due to the lack of qualified employees. Further we do not see a decrease of incoming orders and therefore the machines have to be more and more flexible to reduce delivery times and further increase quality standards.