Hamilton Process Analytics is a division of Hamilton Company, a global leader in precision liquid handling and measurement solutions for research, education, and industry. The process analytics division pioneers open sensing solutions to enhance the understanding and control of critical process parameters. Customer collaboration drives their vision of excellence in measurement technology. A vision that works seamlessly with the infrastructure of today and the possibilities of tomorrow.

Interview with Giovanni Campolongo, Senior Market Segment Manager at Hamilton Bonaduz AG.

Easy Engineering: What are the main areas of activity of the company?

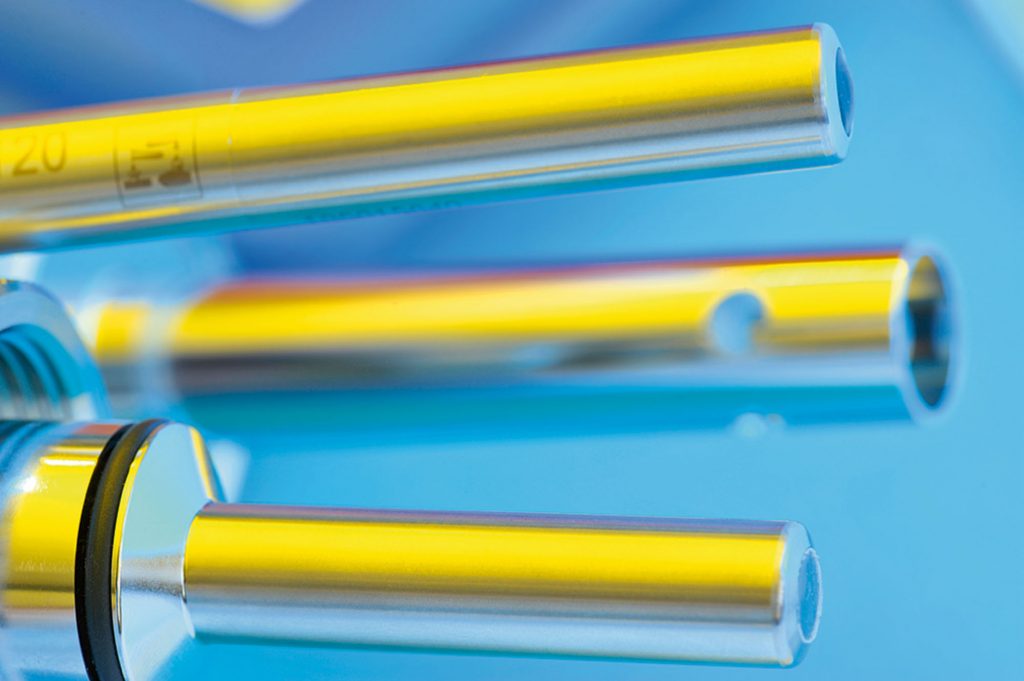

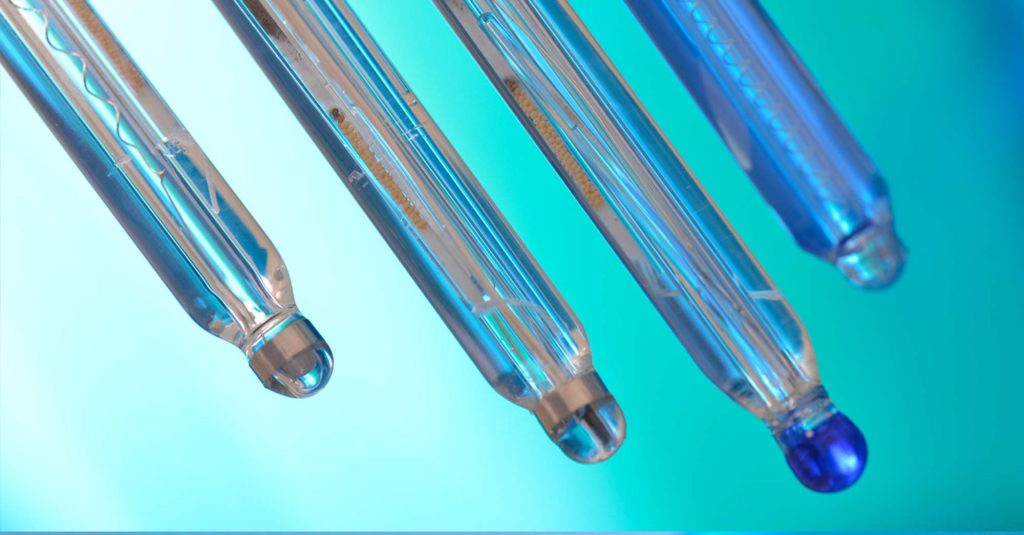

Giovanni Campolongo: At Hamilton Process Analytics, we specialize in innovating and manufacturing of PAT (process analytical tools) for real-time monitoring of CPPs (critical process parameters). Our sensors can accurately measure pH,redox potential, dissolved oxygen, dissolved CO2, conductivity, and cell density. Our flagship product line, the Arc Intelligent sensors, utilizes miniaturized intelligent modules that are integrated into the sensor itself. This technology enables the sensor to transmit a digital interference-free measuring signal with a built-in quality indicator and essential qualification and validation data. It also makes easy and space-saving integration into bioreactors and other process equipment possible.

We primarily serve customers in the biopharma, biotech, and cultivated food industries, providing them with reliable and accurate sensing solutions that help them optimize their processes and achieve their goals.

E.E: What’s the news about new products?

G.C: At Hamilton Process Analytics, innovation is at the heart of everything we do. Our mission statement, ‘With our pioneering sensor technology, we solve biopharma challenges,’ reflects our commitment to developing cutting-edge solutions that enable biotech companies to optimize their processes and achieve their goals.

Over the last two years, we have launched several innovative sensors for the biotech industry:

Our Incyte sensors enable inline measurement of viable cell density, reducing labor work and enabling process automation triggered by viable cell counts.

Dencytee Arc is a breakthrough sensor that allows total cell density measurement over the whole bio-process range. With two built-in measuring principles, it is the first solution on the market to enable in-line measurement of cell density for low to high cell density cultures and fermentations.

CO2NTROL is the first almost maintenance-free CO2 monitoring sensor, using innovative solid-state optical technology.

Our complete portfolio of single-use sensors measures the same critical process parameters as our reusable sensors, eliminating the need for cleaning, validation, and decreasing downtime and turnaround time.

Our proven track record of launching innovative sensors for the bioprocessing industry is a testament to our commitment to delivering exceptional solutions to our customers.

E.E: What are the ranges of products?

G.C: We pioneer high precision process sensors for the real-time monitoring of critical process parameters such as pH, redox, dissolved oxygen, Dissolved CO2, conductivity, and cell density. Our sensors are available with our innovative Arc technology that consist of miniaturized intelligent modules that are built into the sensor itself and enable the sensor to stream a digital interference free measuring signal with built-in quality indicator and important validation data. Furthermore, it allows for an easy and space saving integration into bioreactors.

Although our product portfolio addresses several industries, our core customers are biopharma, biotech, and cultivated food industries.

E.E: At what stage is the market where you are currently active?

G.C: Global (bio)pharmaceutical manufacturers face intense competition and increasing pressure to improve production efficiency. While digitalization and Industry 4.0 can support these goals, the unique challenges facing pharmaceutical manufacturers must be addressed. The Industrial Internet of Things (IIoT) presents opportunities for improving asset performance and operational efficiency by harnessing data through smart devices and real-time analytics, such as our Arc sensor portfolio. IIoT technology can enhance manufacturing, operation, and maintenance management by integrating smart devices with user-oriented software applications.

In addition, the industry is under tremendous pressure to expedite the delivery of drugs to market, as demonstrated during the COVID-19 crisis. Our single-use portfolio offers our customers a faster installation and validating process equipment, enabling them to produce safe drugs more quickly.

At Hamilton Process Analytics, we recognize the importance of addressing these unique challenges facing the pharmaceutical industry. Our Arc sensor portfolio and IIoT solutions are specifically designed to support pharmaceutical manufacturing, ensuring improved operational efficiency, accelerated drug production, and enhanced asset performance

E.E: What can you tell us about market trends?

G.C: In our core market of biopharma/biotech, we have identified several key trends shaping the industry. Digitalization and Industry 4.0 are becoming increasingly important, but we also see other patterns emerging. For example, the use of single-use equipment is on the rise as it offers a smaller footprint, greater flexibility within biopharma plants, and faster time to market, all while reducing the need for cleaning and validation efforts.

Another important trend is the move from batch-production to continuous production, particularly (e.g., perfusion bioreactors). These technologies enable more efficient and streamlined manufacturing processes, improving productivity while reducing costs.

At Hamilton Process Analytics, we are committed to staying at the forefront of these industry trends, providing innovative solutions like our single-use sensor portfolio and Arc sensor technology to help our customers stay competitive and achieve their goals.

E.E: What are the most innovative products marketed?

G.C: Our Incyte sensors, for example, allow for in-line measurement of viable cell density, dramatically reducing labor work and enabling process automation triggered by the number of viable cells. This breakthrough technology is already having a significant impact on productivity and efficiency in the industry.

Another product that has garnered a lot of attention is our Dencytee Arc sensor, which enables total cell density measurement by using two measuring principles built into one sensor. It is the first solution in the market that allows inline cell density measurement over the entire bio-process range, from low to high cell density cell cultures and fermentations.

Finally, our CO2NTROL sensor is the first almost maintenance-free CO2 monitoring solution on the market, thanks to its innovative solid-state optical technology. This is a game-changer for the industry, enabling more accurate and reliable CO2 monitoring without the need for frequent maintenance or replacement.

Overall, these innovative products are a testament to Hamilton’s commitment to driving progress and revolutionizing the biopharma/biotech industry through cutting-edge technology and superior solutions.

E.E: What estimations do you have for 2023?

G.C: The biopharma and biotech market are expected to consolidate after the unprecedented growth of the past three years, driven by the COVID-19 pandemic. However, the market will continue to expand as new biopharmaceuticals are being developed, such as individualized medicine platforms and cell and gene therapies. We anticipate that our innovative sensor technology will continue to play a vital role in improving process efficiencies and advancing biopharmaceutical research and development.

https://www.hamiltoncompany.com/process-analytics