HEF Groupe, created in 1953, is a world leader in surface materials engineering, capable of proposing to its customers, large accounts or SMBs, a total service ranging from research, through industrial development and technology transfer, to the utilization of processes or the supply of components.

HEF Groupe is composed of 86 industrial plants in 21 countries, 3150 collaborators.

Interview with Hervé Delorme, Marketing Director at HEF Groupe.

Easy Engineering: What are the main areas of activity of the company?

Hervé Delorme: Construction, mobility, defence & spatial, medical, decarbonized energies.

E.E: What’s the news about new products?

H.D: New processes focus on the planetary challenges: Circular economy, with recycling and zero polluting waste;

Treatments and coatings advantageously replacing hard chromium and nickel plating;

New products: Coating materials solutions for green energy, for e-mobility, for aerospace and defence.

E.E: What are the ranges of products?

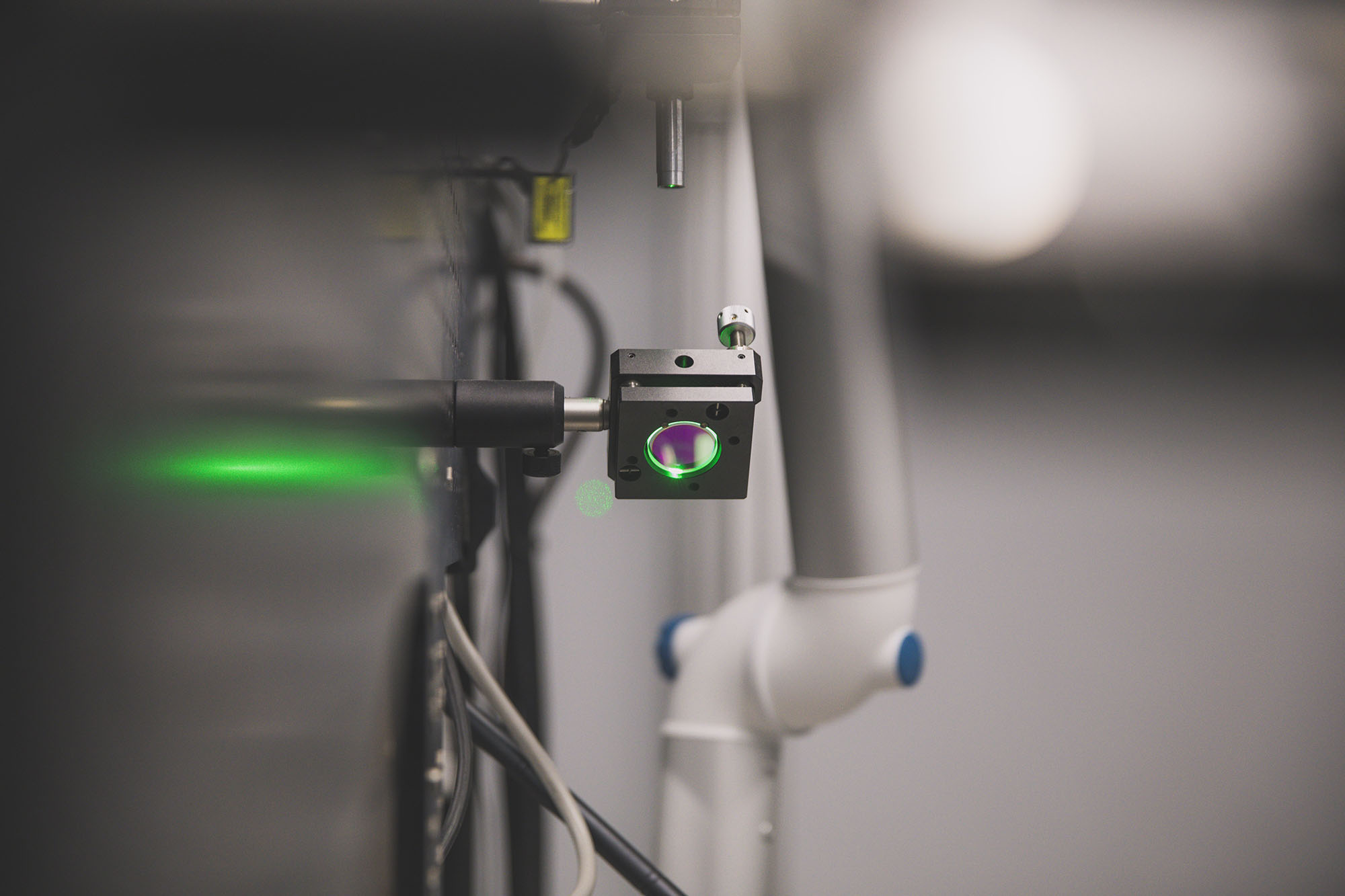

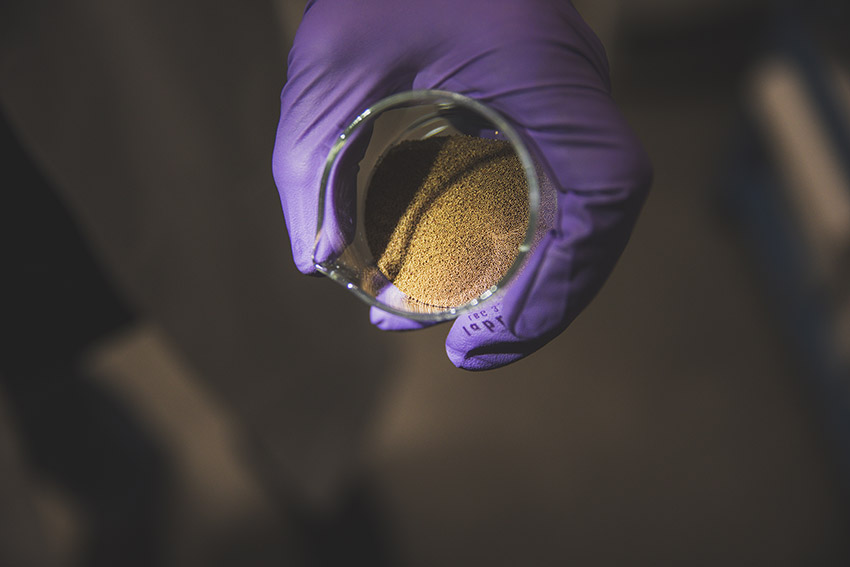

H.D: The HEF Groupe aeras of expertise are: tribology, photonics and hydrogen technologies.

E.E: At what stage is the market where you are currently active?

f H.D: From mature, such as anti-wear and friction for mechanical components, to innovative and disruptive such as eco-friendly and secure solutions for energy production, and many others at the research and development stage.

E.E: What can you tell us about market trends?

H.D: The market dramatically accelerates for new mobility applications, green and sustainable energy and polluting solutions replacement.

E.E: What are the most innovative products marketed?

H.D: One can list the vacuum coatings for hydrogen technologies, advantageously replacing expensive precious metals like gold, to protect the surface of the membranes of the fuel cells and make it affordable for the mobility solutions.

Also, the proprietary nano texturing technique that transforms and functionalizes a surface like micro-machining, to replace chemical hazardous processes, and obtain a level of precision and definition never equaled. Applications are multiple: typography stamps with enhanced precision and lifespan, ultimate dynamic sealing efficiency, etc.

And, if we can limit to 3 examples out of much more in fact, articulation bushing designed for initial greasing only even for heavy loads, suppressing polluting used grease rejects.

E.E: What estimations do you have for the rest of 2022?

H.D:Despite the present difficulties linked to the conjuncture, the rest of 2022 remains promising and allows us to stay on course to double our turnover by 2030.