Founded in 1961, Hoytom has spent over 60 years designing and manufacturing quality control and material testing equipment. Hoytom is making its mark by helping companies to find improvements in the materials they use in their processes; from design, production and final product, via its universal testing machines, pendulum impact testers and hardness testers. Hoytom also provides an on-site calibration and verification service at its customers’ laboratories and is accredited as an ENAC Calibration Laboratory since 1996, which underscores its commitment to quality.

Interview with Borja García del Hoyo, Sales & Marketing Manager at Hoytom.

Easy Engineering: What are the main areas of activity of the company?

Borja García del Hoyo: Within its specialist area, Hoytom provides solutions for all manner of sectors, with established clients in the automotive, aeronautics, metal, paper and cardboard, plastics and wood sectors, amongst others.

Hoytom’s testing machines enable production improvements. The production process is where we can add the most value. What’s important is to make the most of each company’s resources and not waste them. Thus, our machines help companies to make the right material choices for their development or products and thus optimise costs. The wrong choice of material or a poorly executed production process can result in millions of Euros in losses, which is why production line quality control is so important.

One of Hoytom’s strengths resides in the fact that it designs, machines and assembles its own testing equipment which means it has absolute control over each device; its highly qualified staff are very experienced in their manufacture and assembly and employ the machine tools necessary to produce the required quality across the product range.

E.E: What’s the news about new products?

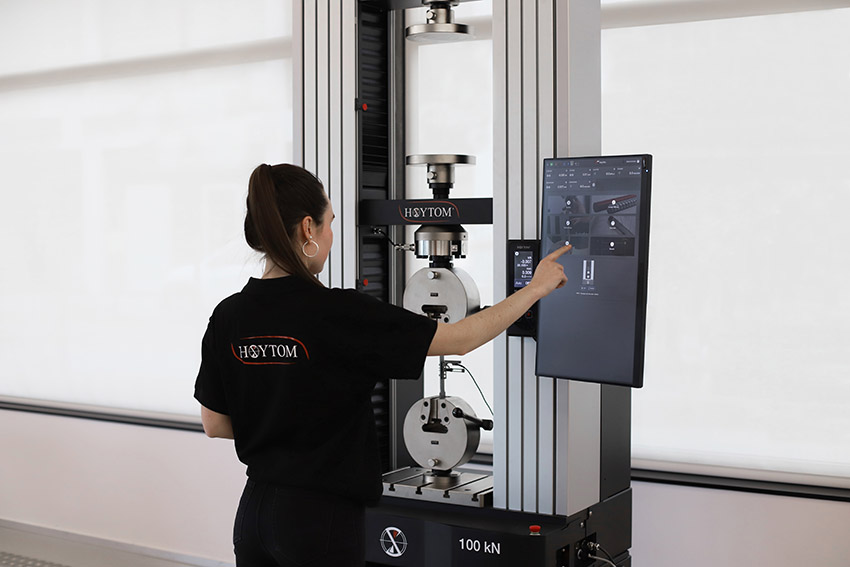

B.G.d.H: One of the biggest new developments at Hoytom is its new HoyWin® testing software, available for all Hoytom universal testing machines. HoyWin® has been designed to be an extension of our testing instruments, providing efficient operation and powerful analytical tools for each test. A new aesthetic and touch interaction functional design enables tests to be performed or consulted regardless of user experience. Its intuitive icons and simple test configuration enable end-users to save time, and intelligently simplify test configuration.

Another recent development is our new HyTT impact tester; its new features and design have been very well received by our customers. Exceeding our initial sales forecasts.

These were the two main novelties presented in May at the Stuttgart CONTROL international exhibition for quality control, which we attend each year as exhibitors.

E.E: What are the ranges of products?

B.G.d.H: Hoytom’s product range consists of universal testing machines, pendulum impact testers and Brinell and Rockwell hardness testers. But the truth is that these standard machines do not always meet customer needs, due to the specific characteristics of the parts or materials to be tested. At Hoytom, providing our customers with a solution to a specific testing problem is something we view as a challenge and is what sets us apart from our competitors. That’s why we make customized testing machines or accessories, studying each customer’s needs together with our R&D department.

Hoytom also offers a machine modernisation service, because we believe older machines should be given a second chance. On the other hand, through our calibration laboratory, we offer calibration services for testing machines and hardness testers at our customers’ premises.

E.E: At what stage is the market where you are currently active?

B.G.d.H: The market wants testing solutions that improve production processes in particular, but Hoytom also provides solutions for product design and the end product. Thanks to our machines all companies involved in the production process for a particular product can meet the relevant standards, ensuring that their process meets regulations and that the next step in the chain does not encounter any problems.

We always speak in terms of ensuring the traceability of the testing of the materials used in each process. It is important to test the product at each link in the chain for the timely identification of any potential anomalies that could spoil an important investment or, even worse, reach the end consumer and not meet their expectations, damaging the company’s image.

E.E: What can you tell us about market trends?

B.G.d.H: There is a clear market trend towards automation and simplification of the testing process. And Hoytom has taken a big step in that direction with its new HoyWin® testing software. Customers appreciate being able to access their testing machine from any device via their LAN without having to install any software. Thereby increasing the possibilities for consultation and test configuration.

Our market is very demanding, as it involves quality control with all that this implies. That is why to give our customers peace of mind with the equipment they purchase, we offer a 3 year warranty on our machines. Something that is not offered by any other testing machine manufacturer.

E.E: What are the most innovative products marketed?

B.G.d.H: HM-D testing machine, with rated capacities from 5 kN to 1,000 kN. An electromechanical testing machine that uses HBM’s world-leading load cell technology to guarantee the quality of the test result. Its Hoytom STARK transmission means reduced noise compared to competing machines and improved rigidity and efficiency.

Another innovative machine is our new Charpy-Izod pendulum impact tester model HyTT. A pendulum that reduces testing times thanks to its hammer that automatically returns to its starting point after each test, thus providing greater productivity and safety for the user. In addition, the easy opening and closing of the sliding door and the possibility of launching a test by simply closing the door enables fast test cycles, very common in the use of temperature-controlled test specimens according to the ASTM international standard.

E.E: What estimations do you have for the rest of 2022?

B.G.d.H: It is difficult to foresee the future of today’s market. The current situation in Europe with high energy costs and the war in Ukraine makes our customers wary of making investments. Fortunately, Hoytom does not depend solely on Europe, and we continue to operate normally in other markets such as America, Africa and Asia. However, we are very optimistic for the future, as cost and production improvements are one of the reasons for purchasing our machines. Companies will continue to seek excellence in a competitive market and that is where Hoytom can provide solutions.