Hubs, formerly 3D Hubs, is an online manufacturing platform for custom parts, that provides engineers with on-demand access to a global network of manufacturing services. Users can easily upload their design, instantly receive a quote, and start production at the click of a button.

Founded in Amsterdam in 2013, Hubs was acquired by Protolabs in January 2021. To date, Hubs has produced more than 7 million parts, using various manufacturing technologies, including CNC machining, 3D printing, sheet metal fabrication and injection molding.

Easy Engineering: What are the main areas of activity of the company?

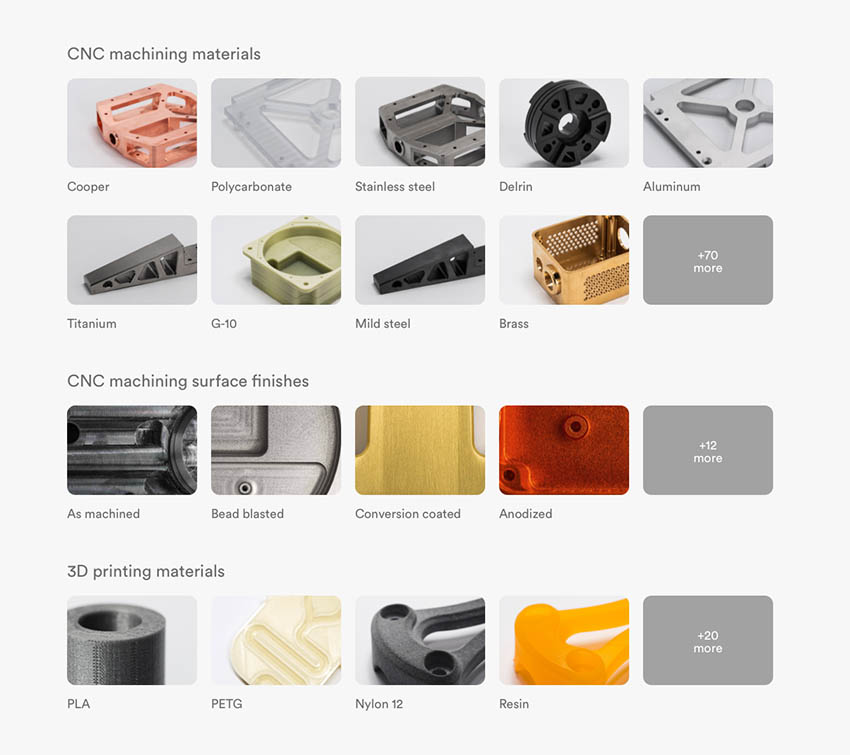

HUBS: Custom, on-demand manufacturing through a highly vetted global network of manufacturing partners, specializing in the following technologies:

- CNC machining

- 3D printing

- Sheet metal fabrication

- Injection molding (through your account manager)

E.E: What’s the news about new products?

HUBS: We recently launched Hubs for Teams, our new solution for helping engineers collaborate with colleagues on manufacturing quotes. This new feature allows a team to work together on quote creation, share the live ordering status at any stage, and view current and past order information. It helps incorporate Hubs into a whole-company workflow, facilitating both inter-team and cross-team collaboration. Customers can sign up for the beta version now.

We’ve also now made it possible to reorder parts from the same manufacturing partner used with previous orders for total repeatability and consistency. Engineers can now select “Reorder from the same manufacturer” in the My Orders dashboard to go from prototype to production with the same manufacturer.

E.E: What are the ranges of products?

HUBS: Online CNC machining, 3D printing, sheet metal fabrication and injection molding for custom parts, from prototyping and tooling to low-volume production.

E.E: At what stage is the market where you are currently active?

HUBS: The online manufacturing market is still rapidly growing.

E.E: What can you tell us about market trends?

HUBS: Online manufacturing marketplaces are speeding up lead times and expanding their services. Hubs joined forces with Protolabs to build the world’s most comprehensive online manufacturing platform. Hubs excels in providing a seamless experience for overseas production, offering complex parts and low-volume production at highly competitive prices. Protolabs is by far the fastest, on-shore manufacturing service in the world. Together we’ll be able to support engineers better than ever before.

E.E: What are the most innovative products marketed?

HUBS: Our pricing algorithm is our most innovative product and allows engineers to see the costs upfront for custom parts. The Hubs machine-learning system analyzes CAD files, and compares it against millions of previously sourced parts (more than 7 million of them), providing users with an instant quote, all in a matter of seconds. Any engineer who has asked local manufacturers for pricing knows that quotes can be wildly different. In the past, there hasn’t been a standardized pricing model for manufacturing. We’re aggregating data from manufacturers around the world and becoming a real-time reflection for pricing in custom part manufacturing.

E.E: What estimations do you have for 2022?

HUBS: 3D printing: Expect new materials and material composites, shorter lead times, lower pricing and more post-processing options to make it easier to integrate 3D printing into full-production manufacturing.

CNC machining: Five and 6-axis CNC machines will speed up production and allow for more complex geometries.

Hybrid manufacturing: More companies will use both additive and subtractive manufacturing to produce parts, opening up new possibilities for design and manufacturing. 3D printing can be used for tooling and custom details, while CNC machining and injection molding can be used for polished finishes, guaranteed consistency and higher throughput.