ICE-Trade ® founded in 2001 in Belgium and is specialized in the supply of Machinery & Equipment for belting service companies and conveyor belt manufacturers.

In January 2017 ICE-Trade sro was founded in the Slovak Republic and since July, after the successful merger with ICE-Trade Belgium, all sales & marketing activities are centralized in Slovakia.

The machines and tools are manufactured in their production facilities in Iława, Poland since May 2007, by ICE-Trade Production Sp. z o.o. Furthermore ICE-Trade supplies conveyor components, belting solutions, rubber & PU sheeting, anti-wear lining solutions, cold / hot bonding and repair materials for conveyor belts.

More than 30 years experience with belting, makes us your competent partner.

For the ICE-Trade Quality, the company is awarded with a very good reputation, worldwide, also thanks to the outstanding team.

All components, parts, steel and trading products, which ICE-Trade uses for the production or sells, are only from renowned European manufacturers.

ICE-Trade believes consideration of the safety, quality, environment, people and community is integral to sustainable development of their business, as well as providing a positive influence environmentally, socially and economically. ICE-Trade’s holistic approach to sustainability incorporates health, safety, environment and community into their Integrated Management System. These drivers guide ICE-Trade’s activities to provide integrity, accountability, transparency and in compliance with the international standards.

Easy Engineering: What are the main areas of activity of the company?

ICE-TRADE: ICE-Trade is active in Europe, Russia, North & South America, Africa

& Oceania

E.E: What’s the news for 2021 about new products?

ICE-TRADE: ICE-Trade developed a fully automatic slitting line for cutting technical fabrics, used for the production of conveyor belts, for a renowned belt manufacturer.

The slitting line features unwinder, slitting machine which also seals the cut edges and a windup. Fabric reels are till 10 metric tons in weight and till 3,2 m wide.

E.E: What are the ranges of products?

ICE-TRADE:

- Machinery & Equipment for the rubber and PVC belting industry;

- Machinery & Equipment for rubber & PU sheet industry;

- Tools for the belting industry;

- Conveyor components;

- Rubber & PU sheeting and lining materials;

- Cold bonding & repair materials for the belting industry.

E.E: At what stage is the market where you are currently active?

ICE-TRADE: The conveyor belt market is and remain very dynamic, even in the Covid period!

Conveyor belts keep on running and running….

More and more belting service companies invest in machines & equipment in order to work more efficient, more ergonomic, more cost effective and with improved quality.

E.E: What can you tell us about market trends?

ICE-TRADE: Due to Covid and the international problems with logistics & transports, more and more belting service companies started purchasing conveyor belts back in Europe instead of the far east. Costs for importing / transport from the far east increased by approx. x 6 compared with the period before Covid. Nowadays the prices for belting and related products, produced in Europe are competitive and are of a constant quality, which isn’t always the case with product from the far east.

Basic materials for the production became more expensive with a 2 digit %, like natural rubber, polyester yarns etc.

E.E: What are the most innovative products marketed?

ICE-TRADE: The ICE-Trade Electric Belt Cutter, developed in 2006, for cutting belts, rubber & PU sheet. Previous there were only pneumatic cutters in the market. By replacing the pneumatic motor with a drilling machine, the Electric Belt Cutter can be used everywhere, even without power supply as we have also the cutters available with a battery operated drill.

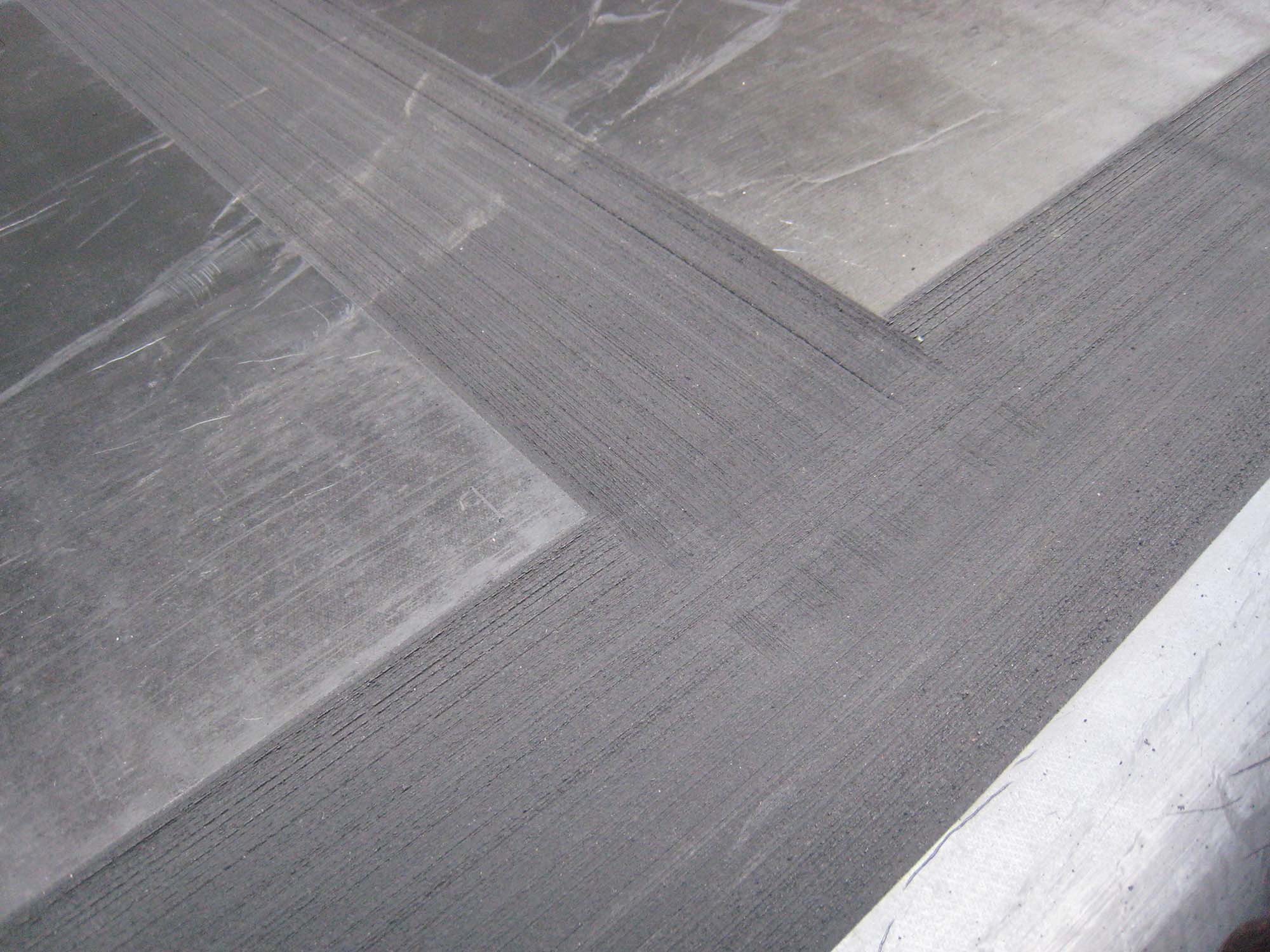

The ICE-Trade Belt Buffing Machine, developed in 2008. This machine is fully automatic, grinding the belt, there where the cleats and or sidewalls have to be placed. Rubber must be grinded, at the contact surfaces of the conveyor belt and the cleats and sidewalls otherwise the adhesion is not good.

Grinding by hand with an angle grinder is time consuming and the quality of the buffed surface is not equal to machinal grinding. Furthermore, machinal grinding is cleaner as a suction system is supplied along for the rubber dust.

E.E: What estimations do you have for 2021?

ICE-TRADE: We estimate that we will have a turnover increase of 5 till 10% for 2021