ICS is a spin-off of the University of Namur, Belgium, with unique expertise in nanotechnology, material characterization, industrial plasma treatment, and numerical modeling. ICS has a very strong innovation capacity: innovation is in our DNA and is a characteristic of our one-stop shop research model: our highly skilled researchers have access to state-of-the-art deposition and analytical equipment answering to the very specific and complex needs of our customers who are looking for disruptive technologies and solutions which are not yet available on the market.

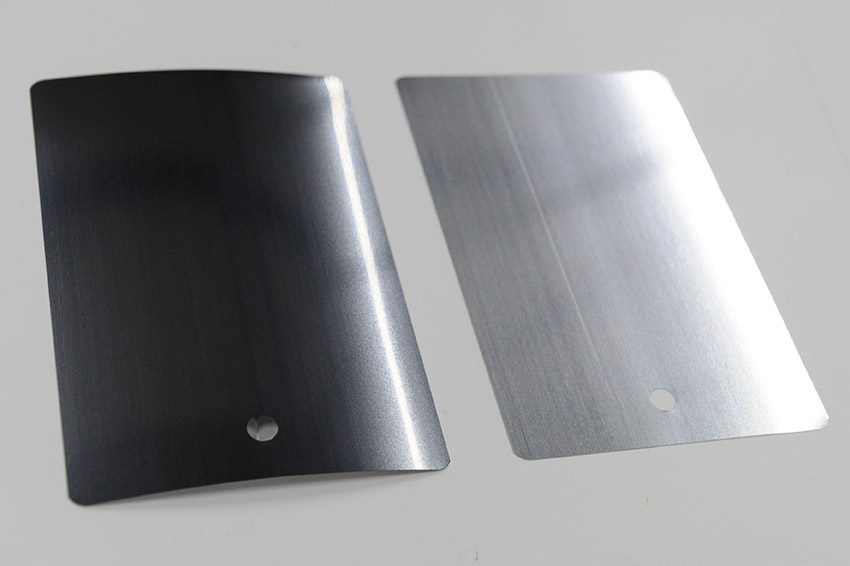

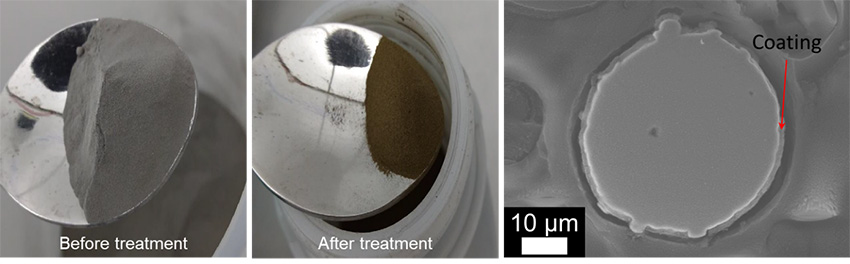

ICS focuses on low-temperature/low-pressure plasma deposition techniques allowing the treatment of metal, ceramic, glass, and polymers/elastomers under powder form or on 2D-3D solid parts. In addition to its core expertise, ICS offers pre- and post-treatments, numerical modeling (prediction of coating deposition and properties), and characterization. We improve/confer properties such as adhesion, anti-wear, conformability, anticorrosion, decorative, tunable electrical conductivity, etc.

ICS business model is organized around 5 axes:

- Job coating: ICS coats parts for its clients. We apply coatings made following our own recipes based on the customer’s needs;

- R&D consulting in coating: ICS develops tailor-made coatings with the aim of answering very specific needs, such as metallic, oxides, or soft DLC for various applications;

- Licensing: ICS licenses and installs its proprietary processes for use on existing machines without disrupting the production cycle, or alternatively, installs & integrates new PVD machines integrating our technology in production facilities belonging to its customers.

- Consumable supply: ICS sells sputter targets for PVD users.

- Modeling and Simulation: ICS provides simulation services for coating deposition by PVD techniques, and commercializes a Monte-Carlo simulation software simulating in silico the growth of thin films deposited by PVD.

Easy Engineering: What are the main areas of activity of the company?

ICS: Our company is specialized in surface modification for any high added value products, using low environmental impact plasma processes.

We are not focusing on any specific markets or applications. The areas of activity of ICS are wide and depend on the unique properties needed by our clients for their final products.

These properties can be for instance higher hardness, high electrical conductivity, or a vivid and scratch-resistant color. The corresponding markets include among others mechanical engineering, energy storage materials, luxury and decorative applications.

ICS is therefore a highly specialized player active in various markets, such as energy storage (battery, fuel cells and electrolyzers), mechanical engineering, luxury, machining, life sciences and decorative markets.

E.E: What’s the news about new products?

ICS: The new products that ICS developed recently are coating with vivid color that does not depend on the viewing angle, antibacterial coating, various coatings applied on powders and small parts, and coatings for dry machining.

E.E: What are the ranges of products?

ICS: Infinite: ICS proposes tailor-made solutions including specific developments to the benefit of its customers.

E.E: At what stage is the market where you are currently active?

ICS: ICS is active at three stages:

R&D project: when a customer wants to develop a specific product that involves surface modification without having the corresponding expertise/know-how in house, ICS proves to be the partner of choice;

Prototyping/small production: when a customer needs a specific coating for its product, ICS provides the coating service using its own equipment.

Full production: ICS provides a full coating production, either on its own equipment, on the existing equipment of the customer, or on new equipment designed for this process. ICS is able to propose a turnkey solution including the design of the equipment in association with coating equipment manufacturers.

E.E: What can you tell us about market trends?

ICS: A particularly hot topic is currently energy storage. The market for batteries, fuel cells, and electrolyzers are currently booming due to the global frame of energetic transition. In this view, ICS proposes several solutions with high-performance coatings for fuel cells and electrolyzers and coating for active material of batteries, that can make the manufacturing step compatible with water-based processes.

E.E: What are the most innovative products marketed?

ICS: Coating for powders.

E.E: What estimations do you have for 2022?

ICS: We expect once more a strong increase of our revenues spread over our five business axes. We will keep on answering the specific high-value added needs of our growing base of clients, whether those are world leaders, medium sized companies or SME.