Since being founded in 1923, the name IDEAL has stood for continuous innovation and quality in machine and plant engineering. The core competence of the family-run company, which is now in its third generation, lies in resistance welding.

IDEAL’s product range includes welding machines for joining wire, stranded wires, wood and metal band saws, for wire processing, the manufacture of sheet metal products and strip joining. The portfolio ranges from smaller series machines and modular standard models, right through to tailor-made, customer-oriented special solutions.

Consistent further development of the product palette and competent, problem-oriented consultancy have enabled IDEAL to attain a leading position on the market and have made the company a reliable partner for the industry. IDEAL has a skilled network of representatives in over 45 countries, guaranteeing close proximity to customers.

Easy Engineering: What are the main areas of activity of the company?

IDEAL: The core competence of our family-run company, which is now in its third generation, lies in resistance welding.

E.E: What’s the news about new products?

IDEAL: CSR: Play the piano

Assisted reality: Safe, fast, inexpensive and very close – IDEAL’s audio visual service makes machine maintenance child’s play and repair a simple exercise. Downtime is minimized with the Assisted Reality connection. Our customers are supported via mobile phone, tablet or virtual data glasses by our service engineers in the best possible way. With live audiovisual transmission, our specialists receive detailed information allowing them to swiftly identify problems and to quickly correct them with the aid of instructions and projection.

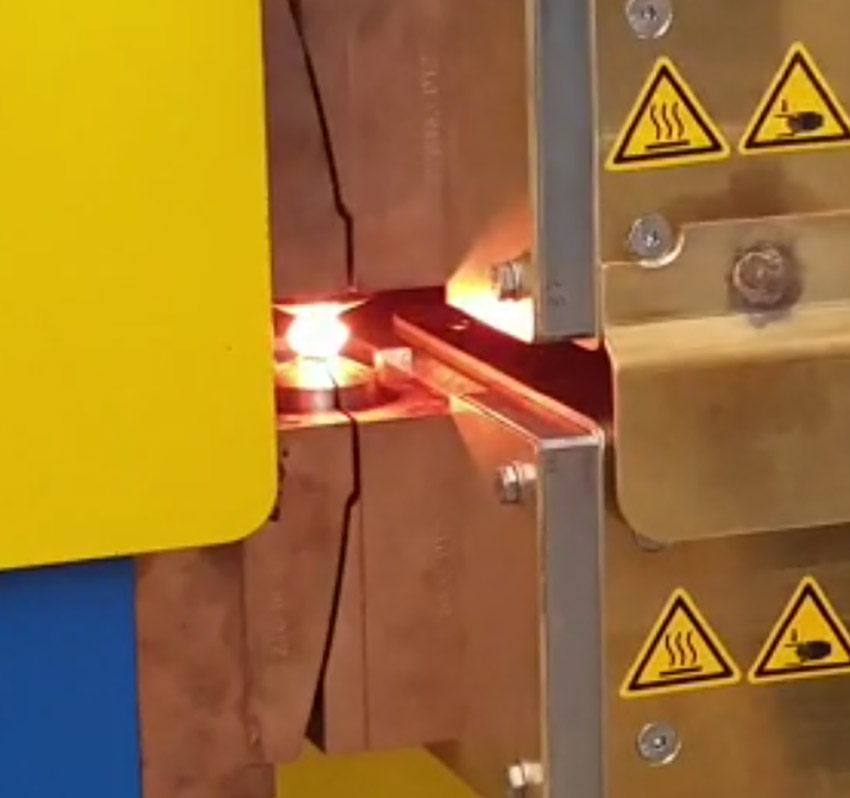

STS 020: With the STS 020 from IDEAL-Werk, the heat-affected material made of iron or non-ferrous metal is almost completely pressed out of the welding zone with force after the welding process. This improves the mechanical properties as well as the design of the weld. With STS type series, high welding quality and enormous strength can be achieved. At the same time the machine is characterized by a high reproducibility of the welding parameters.

The ideal solution for your applications in coil vertical haul-offs of stretching lines and drawing lines.

E.E: What are the ranges of products?

IDEAL:

- wire products;

- wire joining;

- automotive solutions;

- conductors and cables;

- band saws;

- coil joining;

- sheet metal products;

- special solutions.

E.E: At what stage is the market where you are currently active?

IDEAL: -Industrial sector.

E.E: What can you tell us about market trends? / What are the most innovative products marketed?

IDEAL: “Quality or quantity? Which should we focus on?” – IDEAL-Werk offers a solution for both points.

In order to achieve full customer satisfaction and customer experience, both points are addressed and absorbed in the GAM 816. The classic machine for the industrial sector convinces with a new cross wire magazine that runs 200 cycles, representing an increase in quantity. The quality is strengthened by a penetration depth control, as this results in a lower quantity of rejects.

The IDEAL STS 020 butt welding machine is the solution for welding, annealing and shear deburring of wire coil ends in vertical position.

Both a high degree of wear resistance and the separation of a ring-shaped burr into two halves after deburring offer the highest precision. The process sequence of the STS 020 is fully automatic and all product-specific parameters are centrally controlled. Furthermore, the butt welding machine offers parameter control and archiving of welding parameters.