iFactory3D is a manufacturer of belt 3D printers in the field of FDM. Their current core product is the One Pro 3D belt printer for serial additive manufacturing. The company also sells accessories and consumables for said printer model. In addition to selling their own products, the company specializes in developing printers and projects to further automate additive manufacturing.

By sharing their expertise in the innovative 3D printing field, iFactory3D aims to help bring about lasting changes in manufacturing technology and contribute to decentralization of the industry. This includes working with partners to develop appropriate software and optimizing print files so that they can be optimally implemented to save material in the 3D printing process.

Interview with Artur Steffen, CEO and Co-Founder of iFactory3D.

Easy Engineering: What are the main areas of activity of the company?

Artur Steffen: The R&D, production, sales and service for our customers with products developed and manufactured in Germany.

E.E: What’s the news about new products?

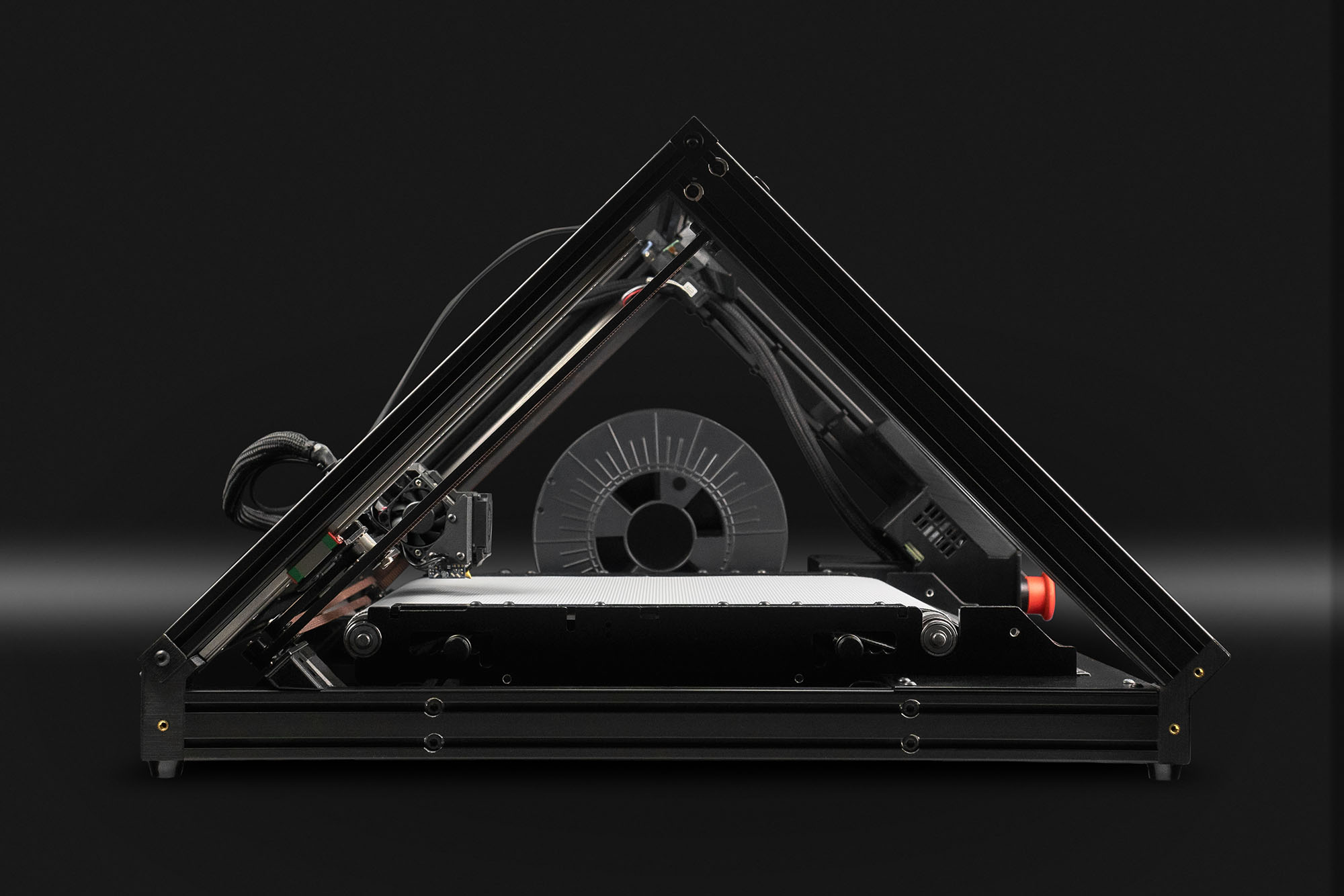

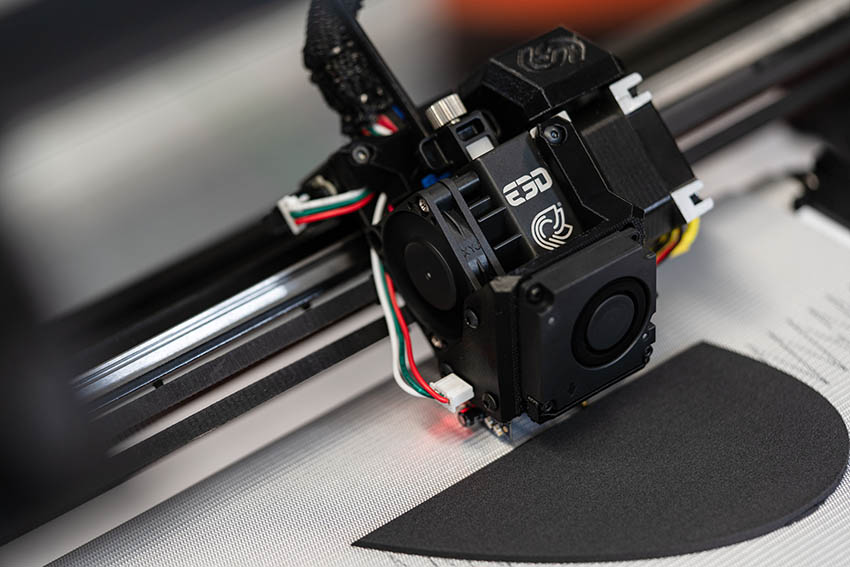

A.S: By integrating a conveyor belt instead of a rigid print bed, length limitations of the print object are eliminated, automated serial print production is possible, and the printing angle of 45° degrees effectively saves material and enables novel geometries that cannot be implemented with Cartesian printer models.

The R&D department is simultaneously working on the market readiness of various alternative 3D printers with conveyor belt technology. These include a modular solution where printers and equipment can be added at will in a closed system. This type of production is especially aimed at companies that are starting or already running industrial production with additive manufacturing.

A printer variant with a wider printing area and the use of several extruders can be used for large spare parts and even more complex designs with advanced part properties.

In addition, a variant with a flatter printing angle is being developed that achieves particularly smooth surfaces and special filling degrees, which are optimally aligned for orthopedic shoe insoles.

The slicer software co-developed by iFactory3D specifically for 3D belt printers is currently in the beta testing phase and will be available to customers once development is complete to optimally align their printing models for the 45° printing angle.

E.E: What are the ranges of products?

A.S: The products developed and licensed by iFactory3D start from high-quality PETG filament and extend to add-on accessories and spare parts for using their 3D printer models. In addition, training, education and maintenance services are offered for the products sold. The implementation of customer orders in the in-house printer farm, as well as the services of the experienced R&D department for individual project solutions for hardware and software in the field of 3D belt technology, are also part of the offered service portfolio.

E.E: At what stage is the market where you are currently active?

A.S: Our market is in the automatization of additive manufacturing. Various companies have different technological approaches to bringing serial production into additive manufacturing. The market for 3D conveyor belt printers is still young and currently served by only a handful of suppliers dealing with this technology. iFactory3D is the only B2B manufacturer in this respect. Our aim is to enable a real non-stop 24/7 serial production via additive manufacturing. From our perspective, companies that regularly need hundreds to several thousand parts will greatly benefit from conveyor belt printing technology. Our focus is primarily on the automotive and machinery industries, but the medical sector, especially the production of orthopedic shoe insoles, is also a promising field for 3D conveyor belt printers. From our perspective, companies that regularly need hundreds to several thousand parts will greatly benefit from conveyor belt printing technology. Our focus is primarily on the automotive and machinery industries, but the medical sector, especially the production of orthopedic shoe insoles, is also a promising field for 3D conveyor belt printers.

E.E: What can you tell us about market trends?

A.S: The trend in 3D printing is steadily moving towards faster and more automated production that can compete with traditional mass production processes, while at the same time offering the advantage of customization. This trend of mass-customization is optimally served by the conveyor belt technology for 3D printing, since a broad product portfolio can be continuously produced with only one machine and a small number of employees. The current economic trend of achieving greater autonomy and being less affected by supply bottlenecks also fits in with iFactory3D’s offering. We promise to continue to grow with more printer models to meet demand and expand as well. This gives the opportunity for real agile production.

E.E: What are the most innovative products marketed?

A.S: The One Pro by iFactory3D is a versatile production machine that has a small footprint and a comparatively low entry price, making it possible for anyone to start production. The machine runs over days if desired and produces with the option of remote monitoring. Our belt printer uses less material when printing large quantities of objects, making it a truly sustainable solution for an already economical manufacturing technology. It has been voted as the product of the year in 2023 by the readers of the “INDUSTRIAL Production Magazine” in additive manufacturing.

E.E: What estimates do you have for 2023?

A.S: We are aiming to launch a new printer model intended for the medical sector before the end of 2023. The further development of the other printer development processes is also part of the planning for this year. For these and possibly holistic new projects, we are focusing on evaluating and incorporating global 3D printing trends into our models. In addition, the spotlight remains on the One Pro, which has recently been selected by several large companies that want to optimize their production processes with the 3D conveyor belt printer. For this, iFactory3D has been officially added to their supplier register as a manufacturer.