IKEUCHI (H. IKEUCHI Co., Ltd) was founded as a trading company in 1954, and in 1961 the ceramic spray nozzle with a precision guarantee was developed. This change was the starting point to the path of becoming a major manufacturer and seller of spray nozzles.

The ceramic nozzle was a successful product because of repeated trial and error process. These ceramic nozzles were quickly adopted and requested by a leading agrochemical spraying equipment manufacturer, who had been looking for a solution to the problem of wear in standard nozzles. This breakthrough facilitated new business opportunities in a wide range of industries.

IKEUCHI was the first company in the world to offer precision guarantee for hydraulic spray nozzles. The company policy was to ship out to customers only the nozzles that complied with specific standards for spray capacity tolerance and spray angle tolerance—a practice that was applicable in the past and carried on in the present day. The guarantee on standard nozzles has served as proof of IKEUCHI product quality, and the company continues to earn widespread customer praise and recognition for these practices.

Currently, IKEUCHI has a high reputation in Japan, while it is expanding in other territories with subsidiaries in China, Europe, USA. IKEUCHI Europe, the European subsidiary is located in Utrecht, the Netherlands.

Interview with Alex Petcu, Marketing Coordinator at IKEUCHI.

Easy Engineering: What are the main areas of activity of the company?

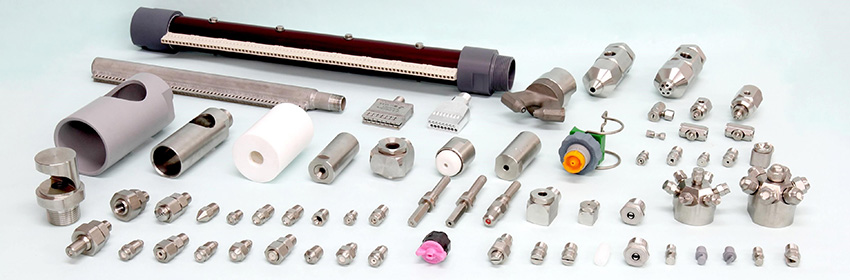

Alex Petcu: The spray nozzle business is the core of IKEUCHI’s operations. This process includes the manufacturing and supplying of suitable spray nozzles for a wide variety of applications and handling and developing custom-made products suitable to the different requests and needs of customers. IKEUCHI utilizes a wide range of product materials, including stainless steel, brass (except EU products), tungsten carbide, standard and high-alumina ceramics, plastics, and other materials, suitable for varied applications and satisfying all customer requirements. Thus, with the development of nozzles from various metals and plastic, the spray nozzles are not only applicable for agriculture use, but for a wider range of industries.

The spray nozzle business further influences 5 specialty business divisions:

- Environment Business – Providing wide-ranging, fog-based solutions that benefit both industry and people’s daily lives

- Humidification Business – Mitigating industrial static electricity problems using one of the world’s most advanced humidification system

- Cooling Business – Fog cooling systems tailored to customer’s industrial needs

- Disinfection Business – Using Dry Fog for disinfection in customer spaces to achieve cleaner environments

- Agro Business – Leveraging fog atomization technology to pioneer new, revolutionary agriculture for the first time worldwide

E.E: What’s the news about new products?

A.P: Since IKEUCHI is renowned for providing innovative industrial products and systems, we constantly invest in research and development to offer our customers the optimum solutions to resolve their issues. To ensure that the quality of the new products is high, IKEUCHI invests in trial-and-error and testing processes, constantly readjusting its products until the delivery of their products optimal. Because of this, for new products to launch, our customers must be patient, however the waiting time is worth it.

E.E: What are the ranges of products?

A.P: For its current product portfolio, IKEUCHI sets strict quality criteria for spray nozzle precision performance, and only the nozzles that pass the inspections based on those criteria are shipped out. Even in the case of customized nozzles with a precise spraying requirement, the company is reassuring the promise of guaranteeing a reliable, safe product suited to the customer’s needs.

The main products that are offered by IKEUCHI are industrial spray nozzles, humidifiers, air conditioners, sterilizing and disinfecting equipment, etc.

There are various types of spray nozzles that are manufactured and sold:

- Hydraulic nozzles

- Pneumatic nozzles

- Air nozzles

- Tank cleaners

Regarding industrial humidifiers IKEUCHI provides a unique Dry Fog humidification system. In addition to the humidifier, the humidification system consists of a deionizer, a control device, a temperature / humidity sensor, piping, and a compressor.

To ensure the well-being of the environment, people and animals, IKEUCHI manufactures and sells equipment and cooling systems. Moreover, in the cooling portfolio there are also cooling devices that aid into cooling solids and gases.

Lastly, IKEUCHI manufactures and sells equipment and disinfection systems that assist in leaving people, animals, and spaces bacteria free.

E.E: At what stage is the market where you are currently active?

A.P: COVID-19 has impacted the industries which IKEUCHI strives to serve. Because of this, the market is more sensitive to price and the customers are more prudent when making choices. However, despite these effects, our company aims at offering a higher value service and a price quality ratio for its products. This is what satisfies and appeals to customers. Currently the market gives some signs of recovery.

E.E: What can you tell us about market trends?

A.P: As noticeable market trends that we have encountered so far, we can mention that everything is more digital. Although we have our business activity in the B2B environment, customers want to encounter the information easily and want a good service besides that. However, our customers also prefer to maintain a personal relationship, since its B2B and not B2C.

E.E: What are the most innovative products marketed?

A.P: One of the most innovative products that IKEUCHI has develop is the AKIMist® “E”. The AKIMist® “E” is the 5th generation type of Dry Fog industrial humidifier. The first prototype was developed in 1980. Since then, IKEUCHI has perfected the way in which the AKIMist® “E” sprays and spread the Dry Fog through the process of impingement. This type of spraying is unique as no other company can replicate it to provide it to the wide audience. Dry Fog is a type of fine fog with a mean droplet of 10μm or less. Moreover, it does not wet its surrounding. Overall, the implementation of the AKIMist® “E” assist with the management and regulation of relative humidity in the industrial setting and provides other by-product benefits, such as: dust suppression, static electricity prevention, cooling effects, providing health-related benefits, while being cost-effective.

The regular version of the AKIMist® “E” comes with a set of stainless-steel nozzles. However, the AKIMist® “E” can also be manufactured with titanium nozzles, which makes it suitable for disinfection purposes.

E.E: What estimations do you have for 2022?

A.P: We would like to say that 2022 is a year of change, innovation, and adaptability. Adaptability to new trends, change in the way we conduct our business and serve our customers, and innovation in terms of providing the products and services that aim at meeting the customers needs. By implementing these traits, we expect 2022 to be a better year than 2021, with more customers but also with new and more challenges.

Facebook: https://www.facebook.com/IkeuchiEU

LinkedIn: https://www.linkedin.com/company/ikeuchieuropeb.v.