Imaginarium is a leader in 3D printing and advanced manufacturing technology based in Mumbai, India. Having pioneered game-changing applications for over 40 industries, Imaginarium has helped disrupt the manufacturing sector by enabling small, medium and large enterprises to prototype faster, design better and take products to market in shorter time spans. Whether it’s manufacturing exquisite jewelry, innovating engineering applications or saving lives with patient-specific medical devices, Imaginarium is committed to seamlessly transforming ideas into reality.

Imaginarium’s state of the art factory and on-demand manufacturing network, along with engineering and design talent, is constantly engaged in making their global clientele improve their products and upgrade their supply chain.

All their services are made available through an innovative Online Factory that makes project execution quick, easy and always-on.

Easy Engineering: What are the main areas of activity of the company?

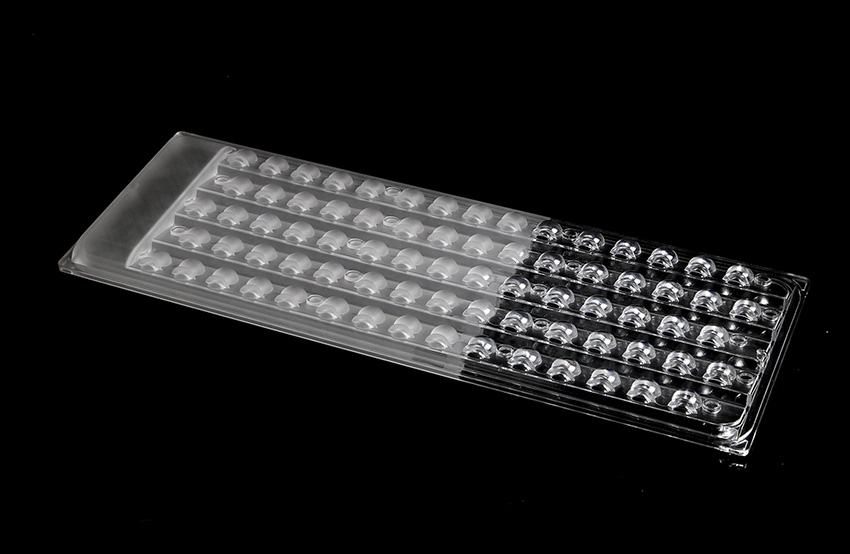

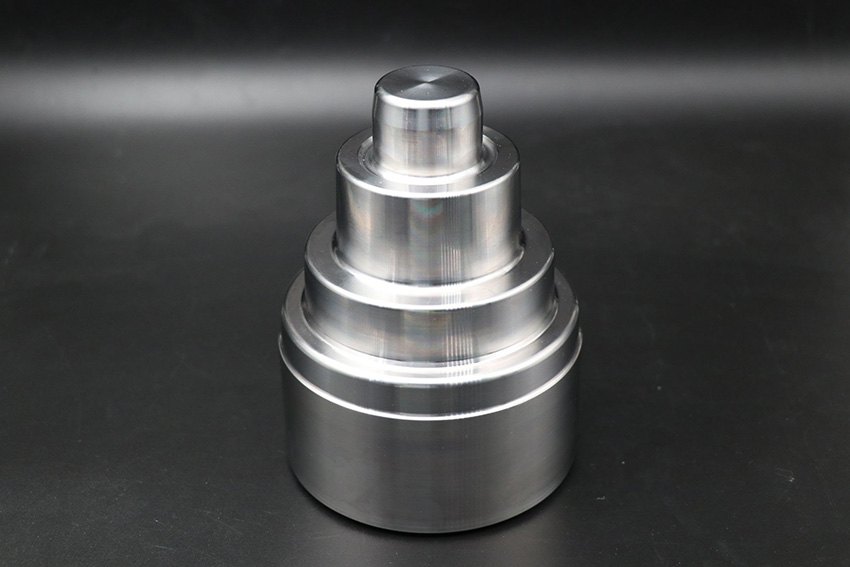

IMAGINARIUM: We thrive on as Consultants first, then vendors – Having an in house design and production facility consisting Additive Manufacturing, Vacuum/urethane Casting, CNC Machining and Injection Molding and we provide a hand-held experience to the designer or engineer to select the right process, material and finish tailored to their requirements and application. Imaginarium brings an experienced team of specialists to consult clients and help them overcome challenges associated with product development and short batch manufacturing operations.

We operate at every stage of the product development journey, helping our clients adopt the latest in design and manufacturing technologies. Our key services are: Design for Additive Manufacturing, Engineering Analysis, Prototyping Services, Low Volume Production, Contract Manufacturing, Turnkey Additive Manufacturing Lab Set Up.

The top industries that we cater to: Automotive, Aerospace, Defence, White Goods, Medical Devices, Consumer Electronics, IOT, Jewelry & Accessories.

E.E: What’s the news for 2021 about new products?

IMAGINARIUM: In 2021, we plan to further push forward on our mission to make Design and Manufacturing accessible to everyone.

Over the past decade, we have successfully scaled up from a small prototyping job shop into a one-stop shop for all Design and Manufacturing. We have also successfully taken the entire portfolio of our services online – allowing clients from anywhere in the world to access our Cloud Factory and start their Prototyping and Production projects with us.

We plan to incorporate newer materials and technologies such as direct metal printing for applications in Defence, Aerospace, Medical Implants, Automotive and Tooling.

The biggest hurdle to mass adoption of these technologies has always been Design knowledge. Imaginarium has recently set up a dedicated Design for Additive Manufacturing team that will handhold clients in identification of opportunities and challenges of Metal Additive manufacturing.

We also wish to strengthen our portfolio of global partners who are leaders in their own fields of technology creation, software innovation and materials development – and give them a launchpad into the Indian market. Some of the existing partners include GE Additive, Autodesk, Materialise and Formlabs.

E.E: What are the ranges of products?

IMAGINARIUM: Our key services are: Design for Additive Manufacturing, Engineering Analysis, Prototyping Services, Low Volume Production, Contract Manufacturing and Turnkey Additive Manufacturing Lab Set Up.

E.E: At what stage is the market where you are currently active?

IMAGINARIUM: Our clients come from across the globe – including USA, UK, Europe, Middle East, Singapore and of course India (where we are headquartered).

Globally, the market for advanced manufacturing is in a high growth phase. The number of new entrants are increasing every week, and a lot of the multinational companies are investing big budgets into developing new machines, materials and software. Customers are also well educated about the possibilities of Additive Manufacturing, and therefore more willing to try it out in their workflow. This is a positive sign for early movers like Imaginarium, and we are keen to expand our portfolio of services for the widest audience possible.

E.E: What can you tell us about market trends?

IMAGINARIUM: Industry 4.0 is very real, and it is finally making its importance felt at a time like this. The pandemic put a complete halt to most traditional supply chains, forcing companies to innovate almost overnight and find alternatives. Those who had already invested in distributed manufacturing systems and on-demand production capabilities have clearly benefited in the past 15 months. 3D Printing users across the world could come together as a community and help in developing, producing and distributing a vast range of COVID response products such as testing swabs, ventilator components, face shields, hospital equipment etc.

Similarly, we have already started seeing the first live examples of Metal 3D Printed parts being incorporated into end use products such as Jet Engines, Cars, Medical Instruments and more.

Going by the success of these projects, it is only a matter of time that hundreds of other industries will start taking their first steps towards new technology adoption. The next few years will be the golden years of Additive Manufacturing, marking its transition from a prototyping tool into a full-blown production technology.

E.E: What are the most innovative products marketed?

IMAGINARIUM: We are very proud of the work done by our Biomedical Engineering team, who are involved in life saving applications that make use of the best in Design, Manufacturing and Clinical Science knowledge. We are scaling up certain innovative solutions that will help Surgeons all over the world plan and perform surgeries in a fraction of the time than traditional methods, and with a significantly higher success rate. This will be made possible through a combination of Virtual Surgery Planning software, Custom Surgical Guides and Patient Specific Titanium Implants that are additively manufactured.

Apart from this, we are also working on developing Digital Spare Part libraries for our clients. We help manufacturing firms get rid of unnecessary inventory of spare parts by redesigning, digitizing and producing these parts on demand. Such applications require a close integration of digital technologies, engineering know-how, sophisticated manufacturing processes and subject matter expertise – which is the core of our business.

E.E: What estimations do you have for 2021?

IMAGINARIUM: As the world opens up after the pandemic, we are confident that 2021 will be the beginning of the best growth years for Imaginarium (and Additive Technologies in general). It is difficult to put growth numbers in such uncertain times, but the trends in the market are already pointing in the right direction and we wish to leverage our market leading position to quickly scale up and reach more clients across the world.

At Imaginarium, we believe in providing unmatchable assistance throughout the product life cycle. Our experts are always there to help you to bring your ideas to life from digital drawings to mass manufacturing.