Monitoring machinery in the 21st century becomes an increasingly complex task. There is not only a need for digitalization, but also to manage the increasing complexity of machines and the operations. Additionally, the plant staff is aging and decreasing, creating an additional need for autonomous operations and maintenance.

Industrial Analytics offers a state-of-the-art software as a service solution for machinery and industrial processes that enables the autonomous plant of the future. With a combined 40 years of engineering know-how, their services and products equip operators with deep machinery knowledge and cutting-edge machine learning algorithms. Therefore, optimizing machines and processes to increase energy efficiency, enable prescriptive maintenance and performance optimization is where we set our focus and specialize in.

Interview with Anja Vedder, Managing Director at Industrial Analytics.

Easy Engineering: What are the main areas of activity of the company?

Anja Vedder: Our work focuses on the development of software enabling operational excellence of machines and processes. Our main areas of expertise are in vibration analysis and data analytics both on the edge and in the cloud. With our software-as-a-service business model our clients are gaining actionable insights into their machinery and operations, reducing monitoring efforts, gaining energy efficiency and a prescriptive maintenance which saves resources through an extended remaining useful life (RUL) of equipment and condition-based maintenance cycles. Our technology is in place within energy providers, gas storage and transport facilities, chemical industries, food & beverage manufacturing and in the transport sector.

E.E: What’s the news about new products?

A.V: The increasing energy prices for electricity, oil and gas have stressed the need for energy efficiency within every aspect of our industries. Saving energy has moved from an environmental cause to a sheer economic necessity in the last couple of years.

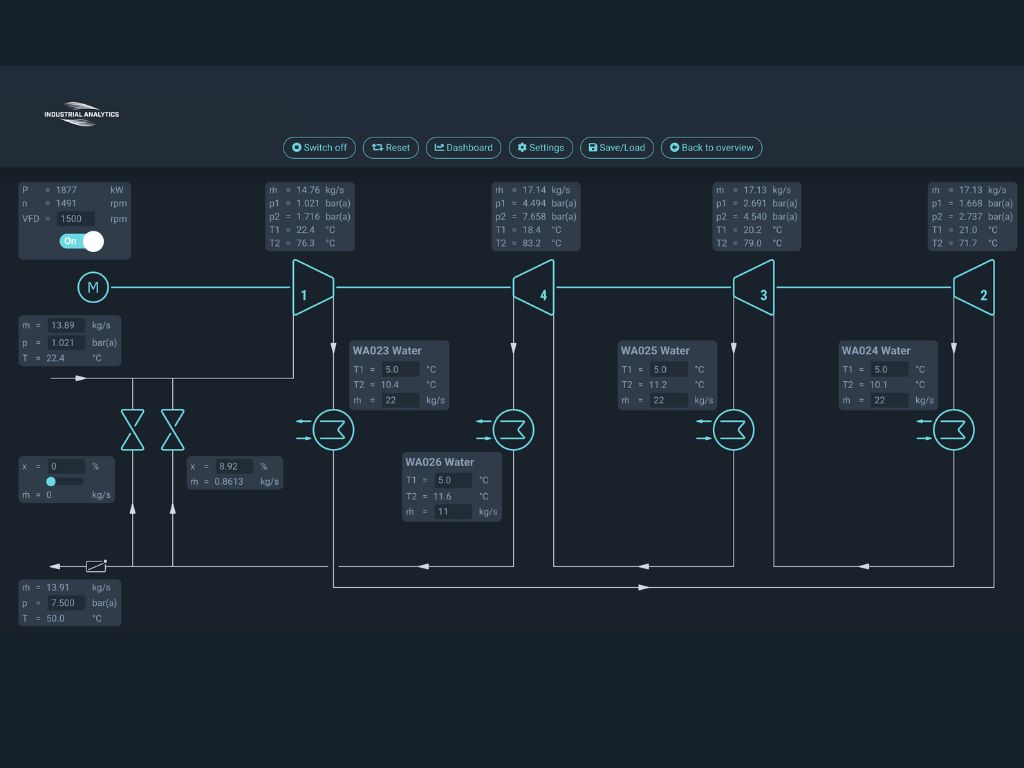

Our algorithms and software enables operators to gain deep machinery knowledge through industrial data analyses. With our digital twins we can translate data coming from machines into actionable insights connected to concrete and executable recommendations for maintenance and the general machine set up. With our modular dashboard and intuitive event management we enable operators to receive recommendations on how to run machinery more efficiently. The physical correlations of the machine are monitored with hybrid models, combining physical models and statistical data to gain a better understanding of the optimal operation. Understanding correlations of components based on physical and statistical parameters, collected data and calculations is a powerful combination to expand operational knowledge.

E.E: What are the ranges of products?

A.V: Our solution is based on our engineering expertise and experience. Our analytics is based on first-principle models and machine learning methods such as convolutional neural networks analyzing time series data coming from machines and processes. With our digital twin the user can understand the correlations within the machinery better and can see the dynamical behavior of the machinery in a digital mapping. In our dashboard we are not only plotting the data from the machinery, but also gathering feedback from the operator through combining supervised and unsupervised learning models. Our algorithms learn from the operator feedback and notify the operator in the future when the failure occurs again.

We use pre-trained models for different equipment like compressors, steam turbines etc., so our clients don’t need to hire extra data scientists to implement our solution. We build a scalable solution with an open IT architecture that is independent from manufacturers and solves client’s challenges.

Anja Vedder, Managing Director at Industrial Analytics

E.E: At what stage is the market where you are currently active?

A.V: We are active predominantly in European markets with a focus on the energy, chemicals and manufacturing industries. Artificial Intelligence as one of our core development resources is gaining further market growth in our target industries with expectations to reach 26.52 billion USD by 2025. The market for predictive maintenance is moving from its experimental and piloting phases towards rapid growth and the need for quick integration on the plant and utility scale level. It is expected to reach 15.9 billion USD by 2026. With these predictions in mind, our products and services are currently well positioned. Current creation of valuable references through our more than 15.000 incoming data streams, are proofing our market ready solution which is set for the future of machine and process optimization.

E.E: What can you tell us about market trends?

A.V: Especially the market of Artificial Intelligence for industrial Data Analysis is expected to grow rapidly. With energy prices skyrocketing, global supply chain problems and the energy transition further accelerating the need for digital solutions that give actionable insights to avoid downtimes, save energy and resources and form the basis for autonomous operations are essential. Big trend is edge computing. We can look back on more than forty years combined industry knowledge on building efficient edge devices with efficient software. Our choices of open source Revolution PI edge devices in combination with cutting edge programming language Julia, make our edge devices and edge analytics incredibly light and efficient.

E.E: What are the most innovative products marketed?

A.V: As mentioned, edge devices are gaining importance in the field of industrial automation and data analysis. But what is often overlooked is the need to build light and efficient edge software. Edge Analytics, a Julia programmed software, enables operators to equip their machines with a very light and efficient software that enables scaling with the least amount of hardware needed. Our approach is to build lighter software that needs the least CPU and memory possible, so that resources of huge edge computing become obsolete.

E.E: What estimations do you have for 2022?

A.V: Engineered Decision Intelligence and Edge Computing For Faster Analysis are leading trends in the Data and Analytics industry for 2022 and are further expanding and are responding to those with our products and services.