INFORM, in general, develops software for optimizing business processes using digital decision making based on artificial intelligence and operations research. They complement classic IT systems and increase the profitability and resilience of many companies. While data management software only provides information, INFORM systems can analyze large amounts of data in seconds, calculate numerous decision variants and propose the best possible solution to the user for implementation.

The company has more than 1,000 customers worldwide, which operate in the fields of manufacturing, logistics, retail, airports, ports, banking, and insurance. Their solutions optimize processes in production planning, workforce management, logistics and transportation, inventory, supply chain management, sales planning, and fraud prevention in insurance and payments.

Easy Engineering: What are the main areas of activity of the company?

INFORM: Our business division production focuses on production planning for contract manufacturers. More precisely, we help single- and small batch manufacturers such as machine and plant engineering companies to create smart and realistic production schedules. We have been in the market for more than 25 years now and know about the various challenges of this specific industry. We have numerous customers that are top tier in their field, ranging from, i. a., drive technology, tooling machines, electrical engineering to solutions for aerospace, plants for filling and packaging, and even pumps and valves. As you can see, our customers’ products are various, but they have to tackle the same challenges, for example mastering the high complexity of their products and production and staying competitive with an increased pressure on the market.

E.E: What’s the news about new products?

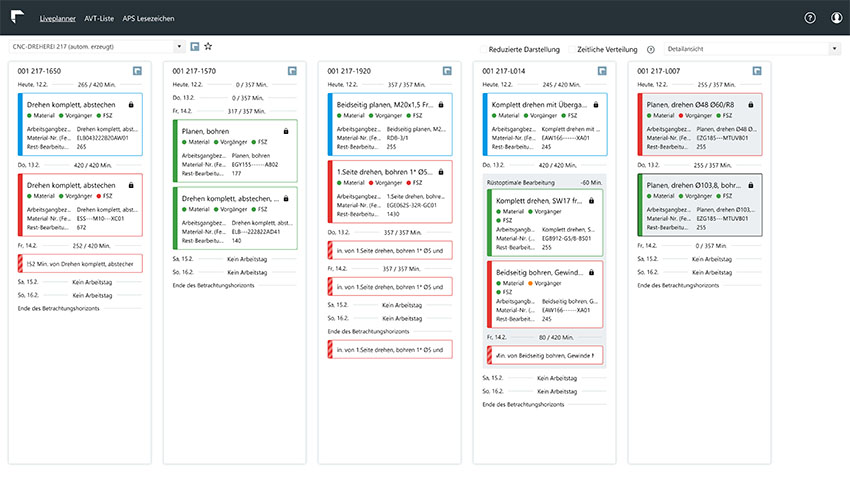

INFORM: The newest addition to our product family for production planning is a module with a real-time planning functionality, called Liveplanner. The web-based interface enables planners to make quick changes via drag and drop in case of a short-term failure or bottleneck. It complements our advanced planning and scheduling (APS) solution with the possibility to compensate inaccuracies in planning data or to react to troubles quickly and precisely without interfering with or negatively influencing the medium- and long-term planning.

E.E: What are the ranges of products?

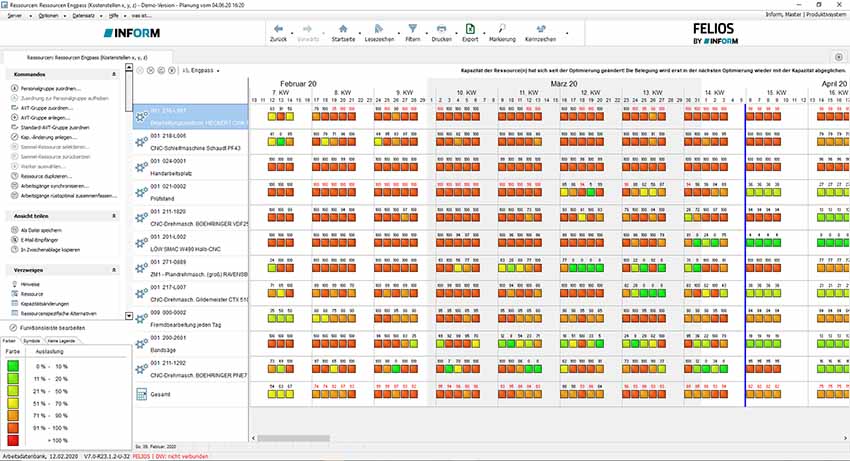

INFORM: Our product family FELIOS is a holistic solution for the production planning of contract manufacturers that works as an add-on to the existing ERP-system and can easily be integrated into the IT landscape. Based on the data from the ERP-system, FELIOS calculates the best possible and most realistic option for the production plan in the long-term and always considers all actually available resources and capacities. In case of disturbances, failures, bottlenecks, or even rush orders, the system gives recommendations for actions to keep the production plan on track. Instead of listening to their gut feeling only, production planners can make well-founded decisions and focus on important things rather than chasing after deadlines.

With FELIOS, our goal is to simplify the lives of production planners and to make companies more agile, resilient, and flexible in their production. That’s why the system is tailored to the special needs of manufacturing companies with single and small batch production and consists of different modules. It connects all relevant data into a single source of truth and plans the production as a whole – whether it’s shift, capacity, and assembly planning or production and machine data collection. The resulting transparency is immense and even cross-departmental.

E.E: At what stage is the market where you are currently active?

INFORM: The need for change is slowly arriving in peoples’ minds. Digitalization is essential to keep up in this highly competitive market. But digitalization alone is not enough. Manufacturers need to optimize and work on their processes to get the best out of it. A digital system can only be as good as its use. People need to work with the systems – that means the way of working has to be adapted. A planning system, such as an APS system, can provide the best production plan, but it will not work if it is not executed correctly by everyone.

Another problem is that many manufacturers only rely on the unrealistic planning of their ERP or limited functionalities of manufacturing execution systems. All these tools have their value and reason for existence, but they leave their users alone with operative decisions that have to be made each day. Intelligent systems collect all relevant data and give smart recommendation for actions with the goal of best overall performance.

As you can see, digitalization is the synergy of different systems, as well as an adaptation of processes and the way of thinking and working. And this is also what we tell our customers and prospects, and we have a feeling that the companies in the market are slowly understanding it.

E.E: What can you tell us about market trends?

INFORM: The customer standards keep rising, everything has to be faster, better, more sustainable at the best price-performance ratio. Manufacturers need to keep up with that or otherwise they will lose their market positions. The only way to do so is by optimizing their processes and that on the other hand is only possible with digitalization. Another thing that the last couple of years have shown is that resilience is crucial to stay competitive. With all the uncertainties that can occur within just a few days, it is important for manufacturers to establish robust processes through optimized and agile planning. This leads to more flexibility and efficiency as well as lower costs, and at the same time strengthens a company’s resilience.

E.E: What are the most innovative products marketed?

INFORM: At INFORM, we combine the best of two worlds. On the one hand, we use data and knowledge-based approaches such as machine learning, artificial intelligence, and operations research, as groundwork for our solutions. On the other hand, we want to get the best out of man machine interactions for the best possible results. The experience, hands-on knowledge, gut feeling, and delegation that our users, e. g. production planners, have, cannot be replaced by a machine, but the intelligence and possibility to calculate the best options in a very short time cannot be done by a human. Therefore, combining these worlds and getting all the different technologies and parts to cooperate is our strategy and basis of all our solutions.

E.E: What estimations do you have for 2023?

INFORM: The challenges in the last years for manufacturers were enormous. The market has calmed down a bit, the order books are filled, but the challenges will not get less. The lack of specialists combined with the demographic change, the high inflation and energy costs, the topic of sustainability, and the ongoing supply bottlenecks – all those challenges will accompany manufacturers in 2023. One of the main solutions and in the end inevitable for companies is digitalization. Digital solutions, such as an intelligent production planning tool, help to, i. a., get the most out of the already short resources. That again plays into the sustainability card.

The future is digital, so is 2023. And with AI and ML, the possibilities are endless.