inno-spec GmbH is an established manufacturer of hyperspectral imaging cameras. Hyperspectral imaging (HSI) creates a chemical image of the investigated goods. This can be used to determine characteristics that are not visible to the eye, e.g. material differences or the quantity of a compound of interest.

inno-spec is a company located in southern Germany, having been successful on the market for more than 15 years now. They sell their products across the world.

Easy Engineering: What are the main areas of activity of the company?

INNO-SPEC: Our focus lies on the research and development of hyperspectral imaging cameras. We have several of them in our portfolio. We also provide equipment like different fore optics, illumination solutions, and specific software packages. In addition, we offer individual OEM components for experienced customers to integrate into their own HSI solutions.

One of our company’s characteristics is our strong customer support along the project, from the initial tests at the customer’s facilities to the final setup. Successful application of this technology heavily relies on long-term experience, and we are happy to share our expertise to get the most out of it.

E.E: What’s the news for 2021 about new products?

INNO-SPEC: We started out with a HSI camera working in the near infrared range, our RedEye 1.7, and we have extended our product portfolio in the last decade. We have now reached a situation where we can cover a high percentage of potential applications with our HSI systems. So, we can spend time to upgrade our devices to meet market needs, e.g. for standardized control and communication interfaces, harsh operation environments, and advanced data pre-processing and correction.

We are fortunate to work alongside our customers and be able to share our mutual experience. Thanks to their constant feedback, we were able to improve our most prominent camera, the RedEye 1.7, and bring it in line with market requirements. We are further planning to revise and upgrade our portfolio to keep pace with latest technology. Currently, we are redesigning our BlueEye cameras for the ultraviolet spectrum which have gained lots of interest in the last few years. More revisions are planned for the future.

E.E: What are the ranges of products?

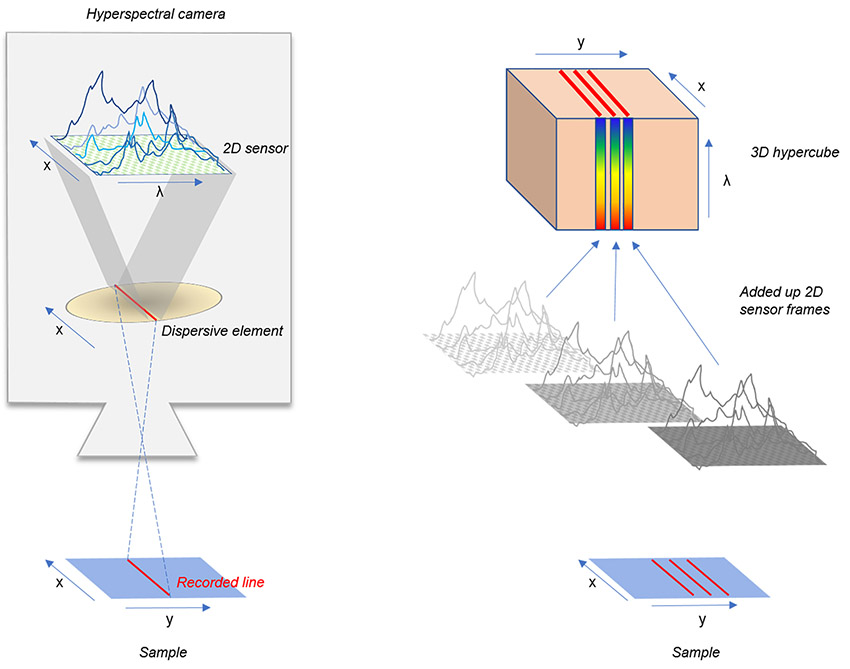

INNO-SPEC: We produce pushbroom HSI cameras. They work as line scanners and enable 100 % analysis of goods travelling underneath the camera, e.g. on conveyor belts. The combination of high frame rates and processing times allows for real-time data evaluation. Our cameras operate in different wavelength ranges to cover a wide section of the electromagnetic spectrum – and thus allow analysis of a wide range of materials. This enables their application in process analytics and in a great variety of manufacturing sectors in general like food, pharmaceuticals, minerals, polymers, wood, waste, coatings, dyes, etc.

Our cameras cover the spectrum from ultraviolet (UV), visible (VIS), shortwave infrared (SWIR) to midwave-infrared (MWIR). All of them can be used in production lines as well as in laboratory research. They are designed to be robust, easy to handle and to integrate. On top, we produce equipment for more flexibility and/or comfort like a motorized stage for samples.

E.E: At what stage is the market where you are currently active?

INNO-SPEC: Hyperspectral technology has been rapidly growing during the past decade. There are lots of networks and corporations formed in this field. Conferences dedicated to HSI have become more frequent. There is a growing number of companies and start-ups specializing on spectral imaging devices and accessories.

Nevertheless, it is still quite a new technology with boundless perspectives for the future, and the range of potential applications where HSI is not yet put to use are vast. Along with that comes the challenge to adapt the technology to the various disciplines. A farming company proceeding tons of crops via automated sorting at a high speed is in a very different situation with regard to material detection, on-site integration and data processing than a mining company interested in mineral classification for automated quarrying, or a research institute investigating additives in polymer melts. That is why hyperspectral imaging has never been available as a turnkey solution. It needs adaption to each and every new field and application.

During our past project implementations, we have had lots of opportunities to learn about the different aspects which need to be considered for a successful HSI operation, especially at the beginning of a project. Our experience gained in close cooperation with some major customers over the last 15 years massively helps us on our way to the optimal solution.

E.E: What can you tell us about market trends?

INNO-SPEC: Hyperspectral imaging is still mainly used by big companies with the resources for the required background knowledge. Yet, the technology is generally expected to experience significant growth in all areas of production, harvesting and waste management in the future. Major global trends like the exploding world population, mass production and the need for clever resource management will run up the demand for efficient and fast supply chains. This is exactly where our technology comes in. More and more companies will discover its benefits and thus boost its popularity and demand. Add to this the constant improvement of the technology itself regarding speed, sensitivity, or compatibility. Multiplied with the on-going digitalization and the yet unconceivable potential of artificial intelligence, those trends will pave many ways for new applications across the value chain, from the manufacturer to the private end-user.

E.E: What are the most innovative products marketed?

INNO-SPEC: First, it is important to understand that hyperspectral imaging products are closely tied to their applications. The products do not stand alone, but are part of a bigger system including e.g. the chemometric software processing and analyzing the data from the recorded images. Depending on the main goal, applications can vary a lot. This variety and customization make the technology demanding, but at the same time extremely powerful and promising for a high number of business sectors. Innovative trends in the waste-sorting industry are boosted by political decisions, and food monitoring becomes an ever-increasing demand. Our already mentioned brand-new BlueEye for the UV spectrum offers a new, innovative range of 220 – 380 nm which will make a lot of yet inaccessible applications possible.

E.E: What estimations do you have for 2021?

INNO-SPEC: The pandemic with its consequences for our business and private lives has proven that technological growth can happen faster than expected. Despite some companies’ desire to refocus on their core competencies, everyone understands that innovation is critical to stay competitive. Last year, a global corporation entered the hyperspectral community by buying one of our competitors. They have sent out a clear signal to the world that hyperspectral imaging is worth investing in. Every crisis is an opportunity for growth. There are many reasons to assume that HSI will deliver positive results for innovative businesses in the future.