Instalo BG has years of experience in the subcontracting and fabrication of metal components/parts and complete products. As a subcontractor, they work mainly for export to Germany, Italy, Spain, France, Belgium, Slovenia, UK, etc.

Easy Engineering: What are the main areas of activity of the company?

INSTALO BG: We, Instalo BG offer subcontracting services for sheet metal fabrication as follows: Laser cutting, Plasma cutting, Bending, Welding, Turning and milling, Drilling, CNC machining, Surface treatment – powder, wet, KTL coating, galvanizing and Asembly.

E.E: What’s the news about new products?

INSTALO BG: We are also proud to announce you, that we are EN 1090-1, EN ISO 3834-2 and ISO 9001 certified. EN 1090 certification is a European standard that outlines the requirements for the execution of structural steel and aluminum components. This certification is important for ensuring the safety and quality of structural components used in buildings and infrastructure. EN ISO 3834 certification is also a European standard that outlines the quality requirements for fusion welding of metallic materials. Overall, these certifications demonstrate our commitment to quality, safety, and efficiency, and can help to enhance our reputation and credibility in the marketplace.

E.E: What are the ranges of products?

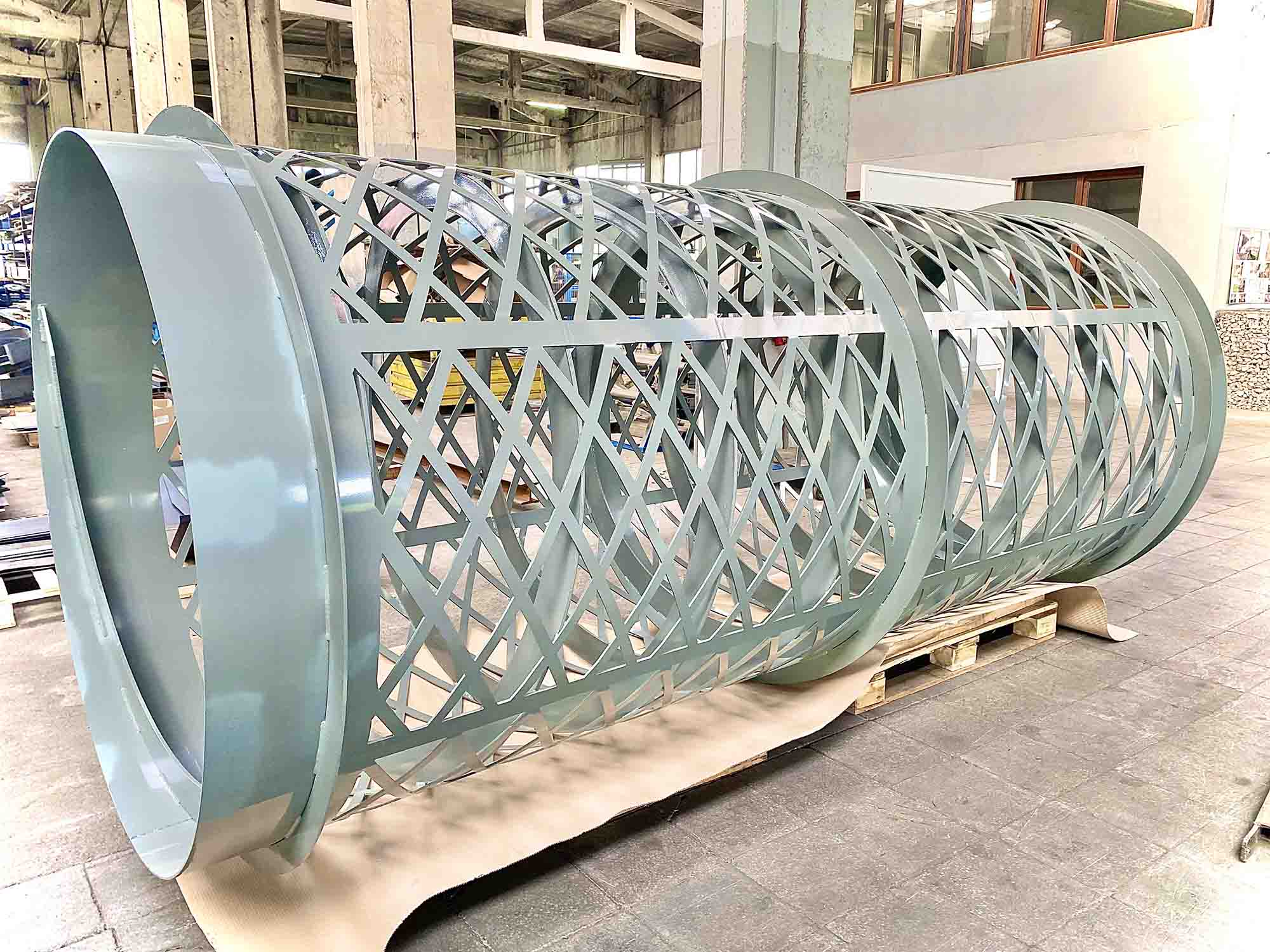

INSTALO BG: Our experience spreads in recycling industry, construction, machine building, packing industry, agriculture, etc. Our portfolio includes also manufacturing of own range of machines as well – equipment for water treatment like screens, conveyors, classifiers, thickeners, etc.

E.E: At what stage is the market where you are currently active?

INSTALO BG: The market for these types of services is generally mature, with established players and a steady demand from both local and external commercial customers. 90% from our market is oriented for export.

E.E: What can you tell us about market trends?

INSTALO BG: However, the market experience fluctuations based on economic conditions and changes in customer preferences or technology. To remain competitive, companies in this market need to keep up with the latest technological advancements and maintain high standards of quality and customer service.

E.E: What are the most innovative products marketed?

INSTALO BG: We can give info about services. The most innovative trends on the market are related to the continuous development of technologies in metal processing, as below:

3D Metal Printing: 3D metal printing or additive manufacturing has revolutionized the metal fabrication industry.

Robotic Welding: It has been a game-changer in the metal fabrication industry, enabling companies to automate their welding processes for increased efficiency and consistency.

CNC Machining Centers: Computer Numerical Control (CNC) machining centers use advanced software and cutting tools to machine metal parts with high precision and accuracy.

It’s worth noting that the metal fabrication industry is constantly evolving, and new innovations are emerging all the time.

E.E: What estimations do you have for 2023?

INSTALO BG: Increased adoption of automation: The trend towards automation is expected to continue in the metal fabrication and subcontracting sector, with companies investing in advanced robotics, CNC machines, and other automated equipment to increase efficiency, reduce costs, and improve product quality.

Growing demand for customized products: Customization is becoming increasingly important for customers in many industries, and this trend is expected to continue in the metal fabrication and subcontracting sector. Companies that can offer high-quality customized products with fast turnaround times are likely to be in high demand.

Emphasis on sustainability: Sustainability is becoming an important consideration for many customers and companies in the metal fabrication and subcontracting sector. This includes reducing waste, increasing energy efficiency, and using eco-friendly materials and processes.

Integration of digital technologies: The integration of digital technologies, such as the Internet of Things (IoT), data analytics, and cloud computing, is expected to increase in the metal fabrication and subcontracting sector. These technologies can help companies improve production efficiency, reduce downtime, and optimize supply chain management.

Skilled labor shortages: The metal fabrication and subcontracting sector, like many others, is facing a shortage of skilled workers. This is expected to continue in 2023, and companies may need to invest in training and development programs to attract and retain talent.

Overall, the metal fabrication and subcontracting sector is likely to continue to evolve and face both challenges and opportunities in the coming years. Companies that can adapt to changing market conditions and leverage new technologies are likely to thrive in this competitive industry.