Ionic Mineral Technologies (Ionic MT) is a battery materials manufacturer based in Utah, USA, with a mission to electrify the future with their innovative next-generation nano-silicon. The company specializes in lithium-ion battery materials using halloysite-derived nano-silicon. The latter is what sets Ionic MT apart in the nano-silicon battery materials field as the mineral halloysite has a unique naturally occurring nanotube structure which is a promising new solution to meeting the demand for higher performance, scalable electric batteries.

Interview with Andre Zeitoun, Founder, CEO & Managing Partner of Ionic Mineral Technologies.

Easy Engineering: What are the main areas of activity of the company?

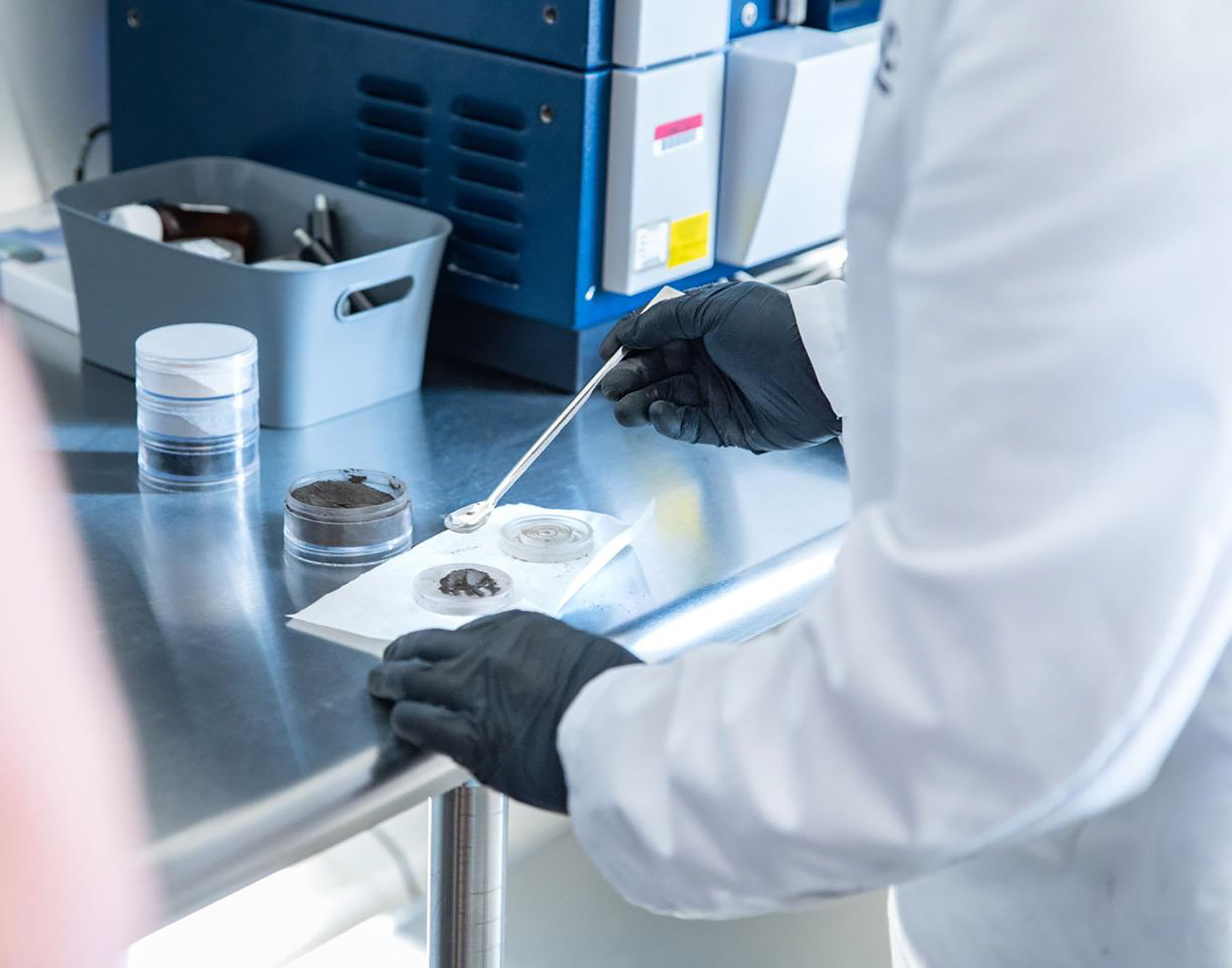

Andre Zeitoun: We are focusing on product development of our nano-silicon anode battery material in our Utah based lab. Ionic MT also controls and operates the world’s largest and purest halloysite deposit based in Utah, meaning we have a critical advantage of high purity feedstock and are equipped to rapidly scale up the material. We have a multi-skilled team of leading battery materials and mining professionals that operate seamlessly through the journey of mining and processing the halloysite to its final product as nano-silicon. Being vertically integrated allows us to have complete control over the quality and scalability of our material.

E.E: What is the news about your innovative new products?

A.Z: Our nano-silicon anode powder product, Ionisil, will be a drop in solution for electric battery manufacturers. Ionisil contains halloysite derived nano-silicon which is an exciting development in lithium-ion battery technology. The naturally occurring clay nanotube structure of halloysite and its silicon-oxide shell means that it can be converted to nano-silicon with significantly less energy than most available nano-silicon products and can easily be scaled up to produce multiple thousands of tons per year using conventional industrial equipment. The manufacturing process is cleaner, more efficient and has the capability to be scaled up more than other products on the market.

E.E: At what stage is the market where you are currently active?

A.Z: The current nano-silicon battery materials market focuses on synthetically manufactured nano-silicon derived from silane gas feedstock using a complex process involving expensive and specialized equipment. Ionic MT challenges this standard with its halloysite-derived nanosilicon and the naturally occurring nanotube structure of halloysite. This means that halloysite can be converted to nano-silicon in a more sustainable way with significantly less energy than most nano-silicon products.

E.E: What can you tell us about market trends?

A.Z: The current electric battery market is under pressure with a demand for faster charging, scaleable batteries, so the industry is clamoring for battery materials that can meet such a demand. Leading the demand, the electric vehicle market is growing exponentially and is projected to reach $824 billion by 2030. In 2021, new EV sales jumped to nearly 9% of global car sales, more than tripling market share from 2019. Further, 60% of new car sales are predicted to be electric by 2030. There are currently shortages of popular critical battery material feedstocks such as graphite, confirming the gap in the market for a next-generation battery material that can meet industry needs. Top EV automakers have found that substituting just 10% of graphite with silicon improves power density over 20% and project that next-generation nano-silicon anode batteries have the potential to double the energy density of current Li-ion batteries with fast-charging over 80% of their capacity in 5 minutes. Ionic MT has established itself as a solution for an increasingly electric future.

E.E: What estimations do you have for 2023

A.Z: We envision Ionic MT becoming an industry leader in nano-silicon anode battery material manufacturing for a cleaner and more efficient electrified future.