ITA TOOLS Company is a Polish manufacturer of professional cutting tools located in Cracow with Production and Service centre in Mielec Special Industrial Zone and warehouse in Wieliczka. In total, ITA TOOLS employs over 140 workers. Withe department in Ukraine over 20 employs and department in Czech Republic 5 employ. We offer a wide range of tools for woodworking industry, furniture production and processing of composite materials.

Easy Engineering: What are the main areas of activity of the company?

ITA TOOLS: Manufacturing and selling of professional cutting tools, for furniture production, woodworking and processing of composite materials. Also, we provide high quality and professional services (sharpening and reparation) all types of PCD, VHM, HM and HSS tools.

E.E: What’s the news for 2020 about new products?

ITA TOOLS: In 2020, we started serial production of VHM router bits for processing of composite materials and light metals such us: magnesium, aluminium, copper, plexiclass, glass or carbone fiber, GFRP, CFRP, Honeycomb, plastics, different types of foam.

E.E: What are the ranges of traded products?

ITA TOOLS: The ranges are:

- Solid carbide spiral bits;

- PCD router bits and cutters;

- Industrial dowel drills;

- Saw blades;

- Cutter heads and pre milling cutter heads;

- Interchangeable and planer knives;

- CNC chuck and accessories.

E.E: At what stage is the market where you are currently active?

ITA TOOLS: The main market for us is Poland but we also open other markets very fast. At the moment, we have regular recipients from around 25 countries.

E.E: What can you tell us about market trends?

ITA TOOLS: I’m sure that the main trend this year and in the next years will be tools with PCD (polycrystalline diamond) plates. This is one of the hardness synthetic material in the world. You can use it for the processing of different materials.

E.E: What are the most innovative products marketed?

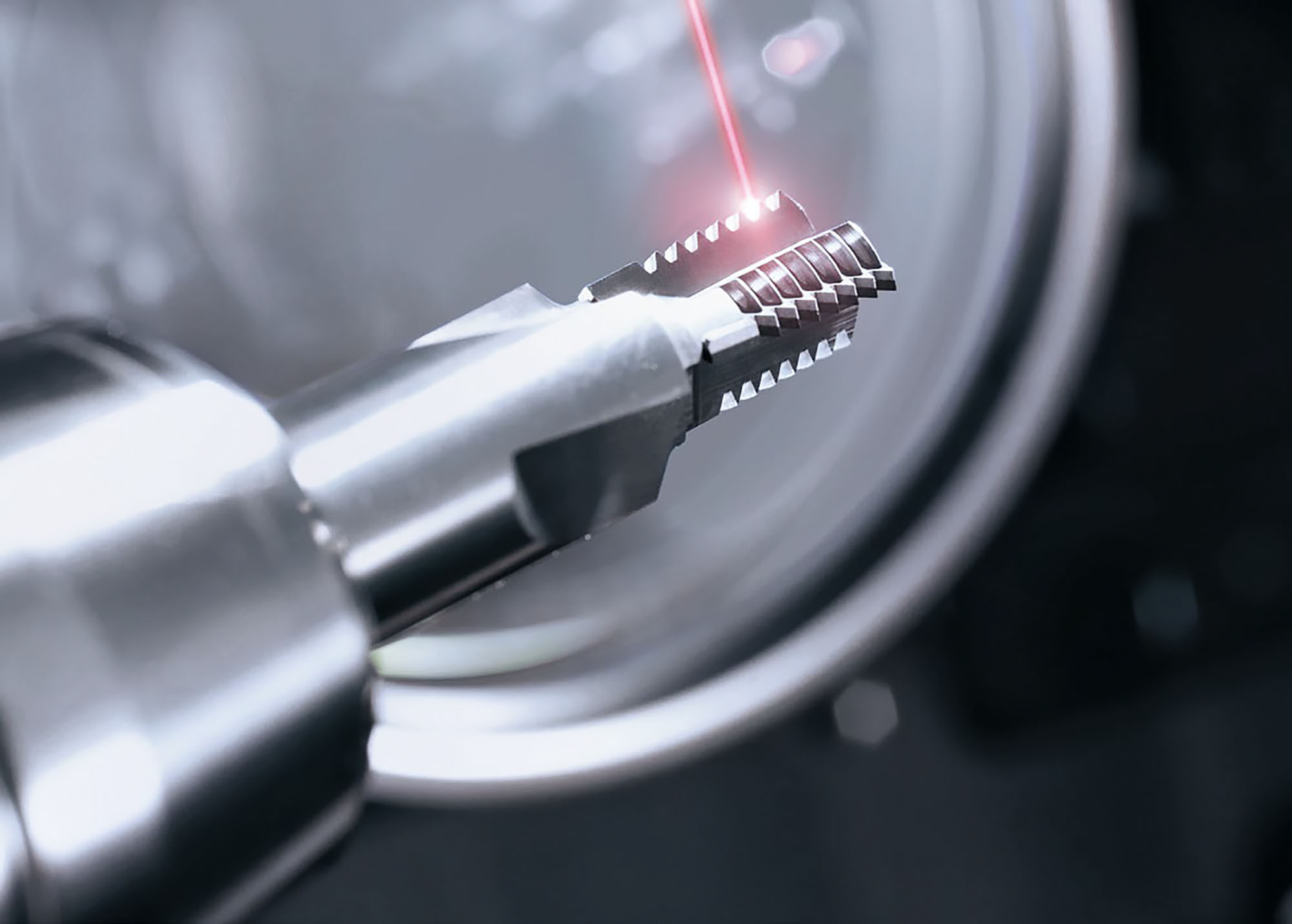

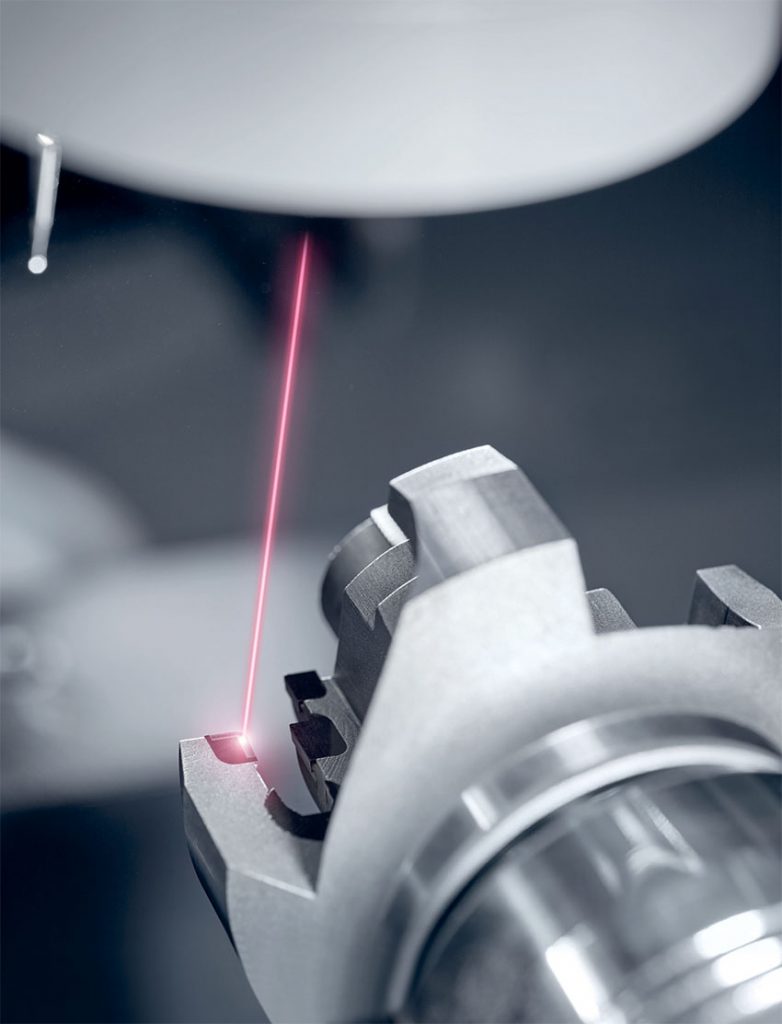

ITA TOOLS: The most innovation products or we can call it service is a new technology of sharpening PCD tools by laser ablation.

ITA TOOLS company is pioneer in technology of PCD sharpening by Laser Ablation.

Laser ablation works by focusing a laser onto a substrate to a remove material that is on its surface. The amount that is removed depends on the intensity, pulse length, and wavelength of the laser, as well as the material itself. The area absorbs the laser that is being directed on it, thereby breaking down the chemical bonds within the area. Laser ablation is a much more efficient, reliable and cost-effective method.)

E.E: What estimations do you have for 2020?

ITA TOOLS: We had a decrease in selling and some problem visiting of costumers in April and May during the lockdown period but now we have an increase in selling. I hope the industry of furniture production will be growing in the next few years because a lot of people are working from home and they will improve their living conditions and an area where they function most of the days. They will be refresh furniture in their houses.