With more than 30 years of experience, Izadi has the specific machinery and knowledge to carry out their commitments. Thanks to the AINGURA IIoT methodologies and technologies, which are developed based on three of their own patents, Izadi is capable of producing high-quality reducers, fully adapted to the real needs of use and with predictable maintenance costs.

Interview with Beltrán Ybarra, Managing Director at Izadi Group & IZDIT.

Easy Engineering: How was 2022 for your business, a short summary?

Beltrán Ybarra: 2022 was a challenging year. Globally, because there were hard circumstances (the supply chain breakdown derivate from the Russia- Ukraine war, or even the inflation) that we had to face. But also locally, because although the year started with many purchase orders, the uncertainty caused by these external circumstances made the companies stagger in the beginning of the year.

Advanced manufacturing and Machine Tool sector reached – in Spain- more than 1.723 million euros turnover, according to the latest report from AFM (provisional figures), that also adds that this was also due to the recovery of activity experimented by automotive manufacturers and the demand coming from energy, aeronautics, capital goods or metal-mechanic industries.

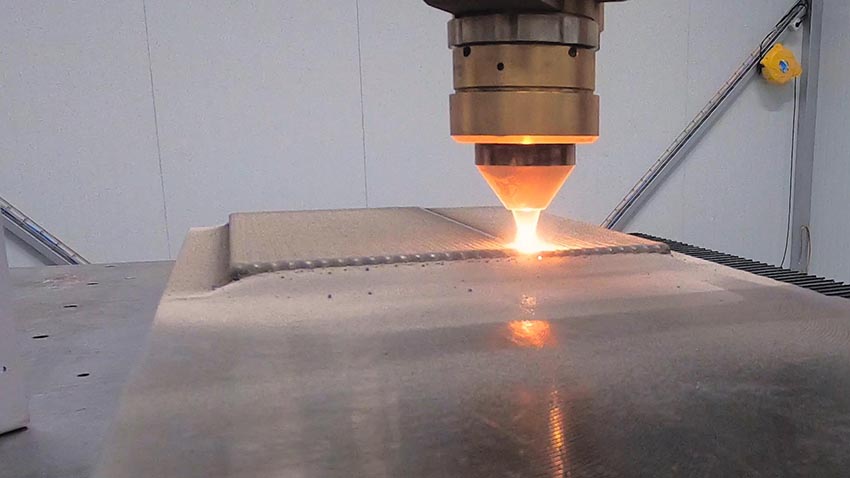

2022 was also a year of launches, as Izadi introduced our two most innovative units to the market, which are focused on gearboxes (IZDIT) and Laser Cladding / Laser hardening services.

It was also a year where we could demonstrate that joining forces with other companies and collaborate with them has a real value, and it´s important to highlight this learning, as well. Thanks to our partners (Talens Systems and Aingura IIoT), we were able to launch our most recent units and this is something I´m really proud of.

E.E: What new products/services will be launched this year?

B.Y: The strategy we follow at Izadi Group is to consolidate the services we offer with the greatest added value, such as IZDIT and Laser Cladding, and to do this, in our opinion, it is necessary to work on their development in the market and how they fit into it.

Therefore, in order to grow or even scale the way we would like to, we prefer to strengthen our newer units, such as gearboxes or laser cladding & laser hardening, rather than launching more products/services this year. In our view, it is time to reap what we sow 😉.

E.E: How did the market change in the last year?

B.Y: At the beginning of 2022, we already knew that automation was one of the pillars of industry 4.0, and how useful it was in terms of growth, constant innovation or even getting new and more agile job patterns.

After Covid19, and in order to be more productive and cost effective, production chains were aware that automation technologies were a must. For that purpose, cloud or digital twins were the main points, but not the only ones.

As we were aware of this automation trend, we took advantage of it and decided to launch Izadi Laser unit on 2022 as well, which it´s a robotized solution with external axes that offers a complete automated process thanks to its CAD/CAM software and the monitorization and alarm system that warranties a perfect execution.

E.E: What were the best-selling products of 2022?

B.Y: As far as the Spanish market is concerned, our best figures come from the Standard Machining unit, which is also the longest-lived and the Izadi Group‘s base. During the company’s 30 years, we have increased our capacities and evolved our services, but we are aware that the increase in new lines of business cannot affect the more consolidated ones such as Standard Machining. For example, we are proud to say that we have loyal customers who trust us -year after year- when it comes to manufacturing complex parts, such as gears, keyways or couplings, because we have the know-how, the experience, the machinery and the people for this type of specific and complex tasks).

Likewise, the development of our high precision business unit (Denatek) in the aeronautical and aerospace sector is being very high and with a high expectation of activity from our customers in 2023.

E.E: What sector of business do you think is expected to grow this year?

B.Y: Innovation is, nowadays, the best investment that companies should make. Artificial Intelligence, Big Data, Machine Learning or Virtual Reality are some of the technologies that help the companies to achieve their goals in terms of productivity and delivery.

During the past years, Izadi Group has made huge investments on innovation, as we believe that we must be at the forefront of the industrial manufacturing sector, at least in Spain, where we have our facilities (although we work also for companies abroad Spain).

Having said this, my opinion goes for Predictive Maintenance as one of the most important growths. And here, we have a great opportunity with our gearbox’s unit. Because at IZDIT, our offering goes beyond designing or building gearboxes, we also maintain them and extender their usable life, thanks to our test bench – co-developed with our partner Aingura IIOT- that allow us not only to evaluate its operational efforts, but also to stablish a programmed maintenance, make an estimation of their usable life or determinate the equipment degradation level and its reasons.

In addition, I believe that additive manufacturing is on the cusp of stardom, which is something that McKinsey experts confirmed last year too. As they said, the point is that “while companies have dabbled in using additive manufacturing for the direct manufacture of final products, large-scale adoption of the approach remains limited”. It´s time to make this technology shine, in order to get faster and more quality services (and here, Izadi Group has a good position in the market as we have diversified our business creating our Laser Unit that offers Laser Cladding based on LMD)

E.E: What estimations do you have for 2023?

B.Y: Our forecasts are to increase our revenue from IZDIT through the design and construction of gearboxes and the Laser Unit, because we really offer a differentiated service: our laser cell is unique in Europe, not only because of its size (300 m2) but also because of what it offers.

Our Laser Cladding and Laser Hardening services allow us not only to perform special coatings, but also to manufacture and repair parts for industrial equipment based on our own CAD/CAM development.

Thanks to these disruptive laser services, our processes add real value to our customers’ needs

E.E: A short message for collaborators for the beginning of the year.

B.Y: Izadi Group is a reliable company where we have 2 mantras:

First of all, our customers are at the center of our strategy, giving them always the best service in terms or productivity, efficiency, delivery and, treatment indeed.

But we cannot forget that this company reached its position in the market thanks to our people. People that get up every morning to give their best at their jobs, and this is something that I need to highlight. Our growth could not have been possible without them. So, let me send them a few words of thanks too.

Anyhow, there are open job positions at Izadi Group. So, if someone of the sector is seeking for a new experience in San Sebastián (Spain), contact us!

IZADI GROUP

Poligono Egiburuberri 21A, 20100 Errenteria – Gipuzkoa (Spain)

Tel.: +34 943 494724

Email: info@izadimecanizados.com