Since 1934, Jacobs Corporation still reflects the same work ethics and business philosophy that their founders demonstrated. Over the years, Jacobs has evolved into a modern manufacturing company with state-of-the-art equipment that is operated by highly skilled personnel. Their continued commitment to quality products, competitive pricing, and leading innovation has enabled them to become a worldwide leader in replacement parts for hammermills and pellet mills.

Interview with Brian Wollaston, National Account Manager / Western Regional Sales Manager at Jacobs Corporation.

Easy Engineering: What are the main areas of activity of the company?

Brian Wollaston: Worldwide leader in replacement parts for hammer mills and pellet mills.

E.E: What’s the news about new products?

B.W: Jacobs Lightning die technology is achieving 30-100% increases in throughput while maintaining, or improving, pellet quality. The best part is these increases commonly come with the same, or lower, energy costs.

E.E: What are the ranges of products?

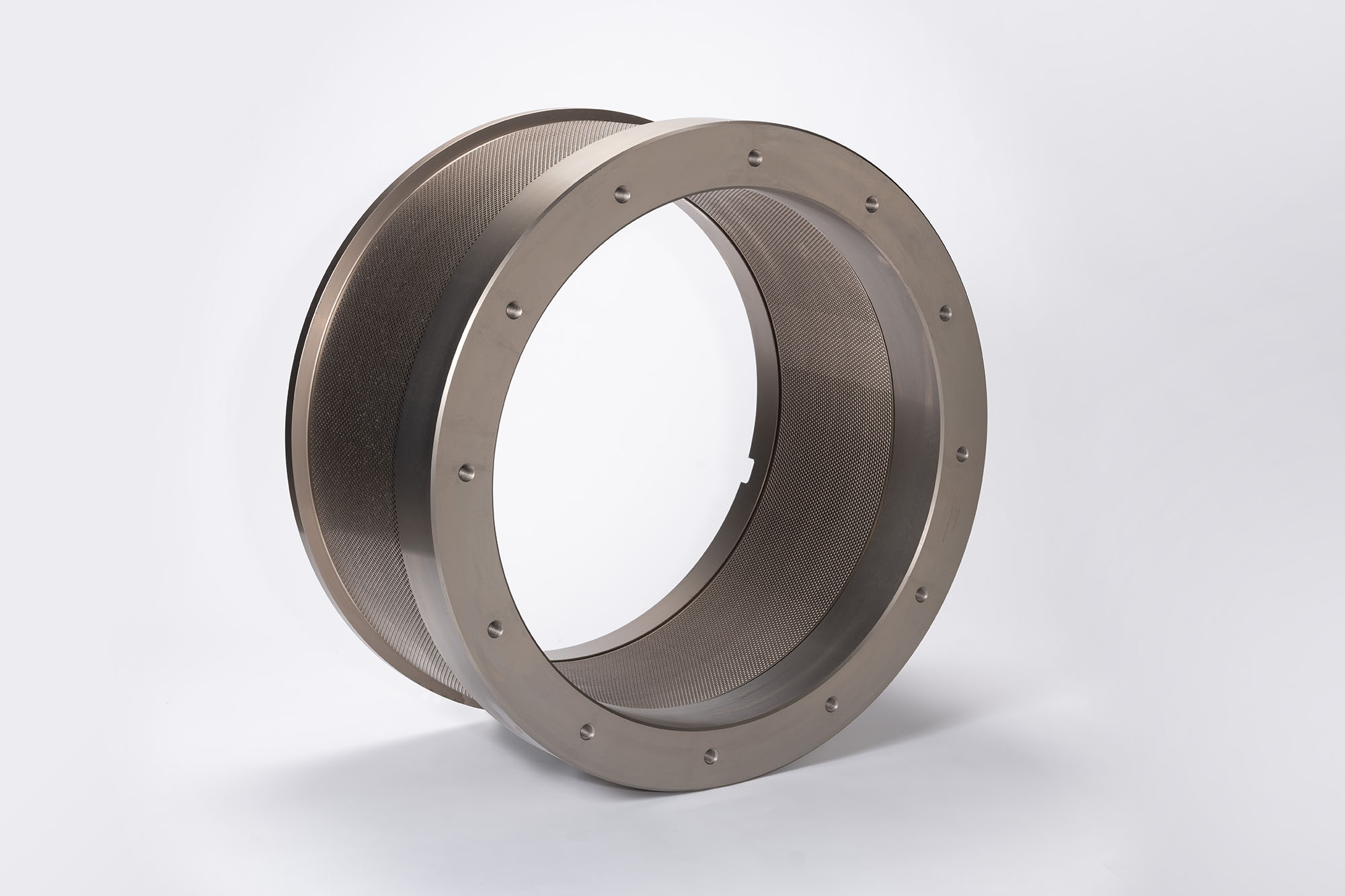

B.W: Jacobs produces pellet mill dies, pellet mill wear parts, roll shells, and die and roll rebuilds as well as hammers, rods, spacers, and screens, for hammermills.

E.E: At what stage is the market where you are currently active?

B.W: Our market is so diverse (broad range of industries we serve and a broad range of countries we sell in) that while one industry might be in slight decline mode others are in growth phases.

E.E: What can you tell us about market trends?

B.W: Employers across all of our markets are struggling to hire and maintain workers. Therefore, mill sizes must increase to produce more product per labor hour and minimize energy costs and downtime.

E.E: What are the most innovative products marketed?

B.W: On the pellet mill side our most innovative product is the Lightning die. These dies produce more tons per hour at the same or less energy as standard chrome dies.

On the hammermill side our premium hammers (Dagger, Dagger clusters, and Pentagons) reduce install time, increase production capacity, and run longer than any other hammers on the market.

E.E: What estimations do you have for the rest of 2022?

B.W: The balance of 2022 we expect the volume of business across all our product lines to remain strong.