Köchel Verifications GmbH is a very young German company founded in 2019. They focus on the measurement of the effectiveness of ultrasound cleaning devices. These devices are used more and more to clean medical and optical devices as well as jewellery, watches or products in laboratories and many more. Köchels’ first public appearance was at the international trade fair for industrial parts and surface cleaning Parts2clean in Stuttgart in October 2019.

The company’s vision is to establish more confidence in ultrasound cleaning by verifying the functionality of the devices through a specified measuring process.

Easy Engineering: What are the main areas of activity of the company?

Köchel Verifications: We have developed, produce and bring to market a system called “cavispector” which measures the cavitation in ultrasound cleaning tanks.

E.E: Why do we do that and what is cavitation?

Köchel Verifications: The cleaning effect in an ultrasound cleaning device is based on cavitation, where small bubbles collapse in an aqueous bath and trigger an impulse on the surface of the goods to be cleaned. This impulse removes the contamination from the goods.

The processes in the production of the products mentioned above are generally defined very clearly and the parameters are controlled. The requirements for the process reliability and its documentation are increasing more and more. But the control of the processes of ultrasound cleaning devices and their effectiveness is not established well enough. Traditional tests with aluminum foils are not safe and are not clearly reproducible, not quantifiable and badly documentable. Alternative tests with tubes with colour change are also only a qualitative dimension.

Up to now, there has been no method to measure the cavitation in the cleaning bath and to verify the cleaning effect, which is freely available and independent of a manufacturer. But this is needed desperately to verify the cleaning of critical products.

Now, cavispector fills this gap!

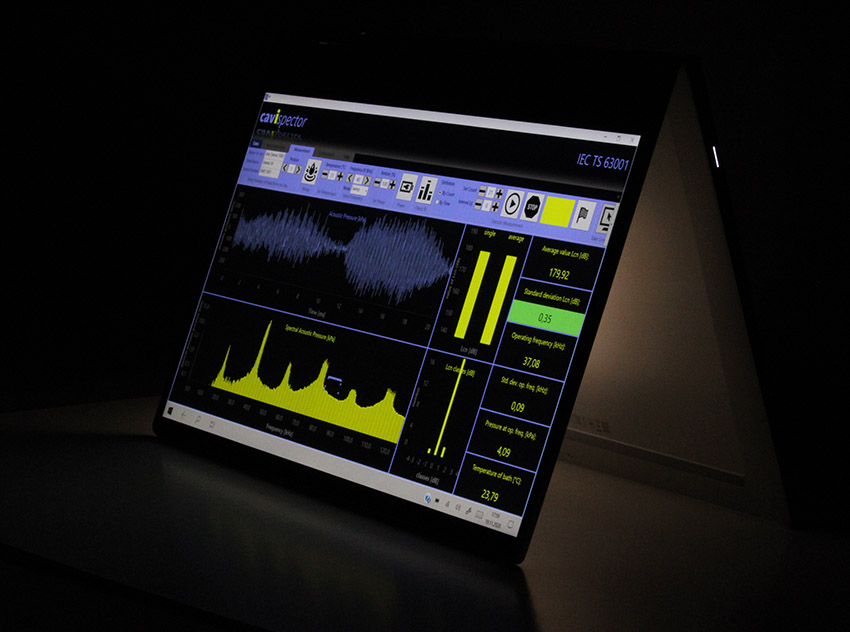

Cavispector measures the cavitation in the cleaning tank, documents all relevant parameters and generates a test record which can be presented to an auditor.

Cavispector completes the chain of validation in the production process and provides security for the user.

E.E: What’s the news for 2020 about new products?

Köchel Verifications: 2020 was the year we made our first sales of cavispector. Together with our customers we have optimized the measuring system and we have added additional features. The graphical user interface was improved even more to safeguard the best possible intuitive handling.

E.E: What are the ranges of traded products?

Köchel Verifications: We offer different services:

- We check the ultrasound cleaning devices of our customers on their premises. They receive a test report which documents the status of their device or line, regarding cleaning efficiency and cavitation.

- We perform projects where we make investigations together with our customers about their cleaning process and we find out measures to improve the cleanliness of the goods.

- We sell the measuring systems to those customers who have a larger number of ultrasound cleaning devices or lines and who have qualified technical staff to perform the measurements by themselves. This is also interesting when they plan to check their cleaning process in shorter intervals or when they want to use cavispector for scientific use.

- We train qualified staff the optimal handling of the cavispector software and making best use of all helpful features and ensuring the best practice of cavispector.

- At the moment we advise our customers on finding out the ultrasound cleaning devices which suit them best. Cavispector enables customers to compare devices from different manufacturers. Also, we can help to optimize the level of cavitation in an ultrasound cleaning device to ensure optimum cleanliness with minimum harm to the goods to clean and the cleaning device.

E.E: At what stage is the market where you are currently active?

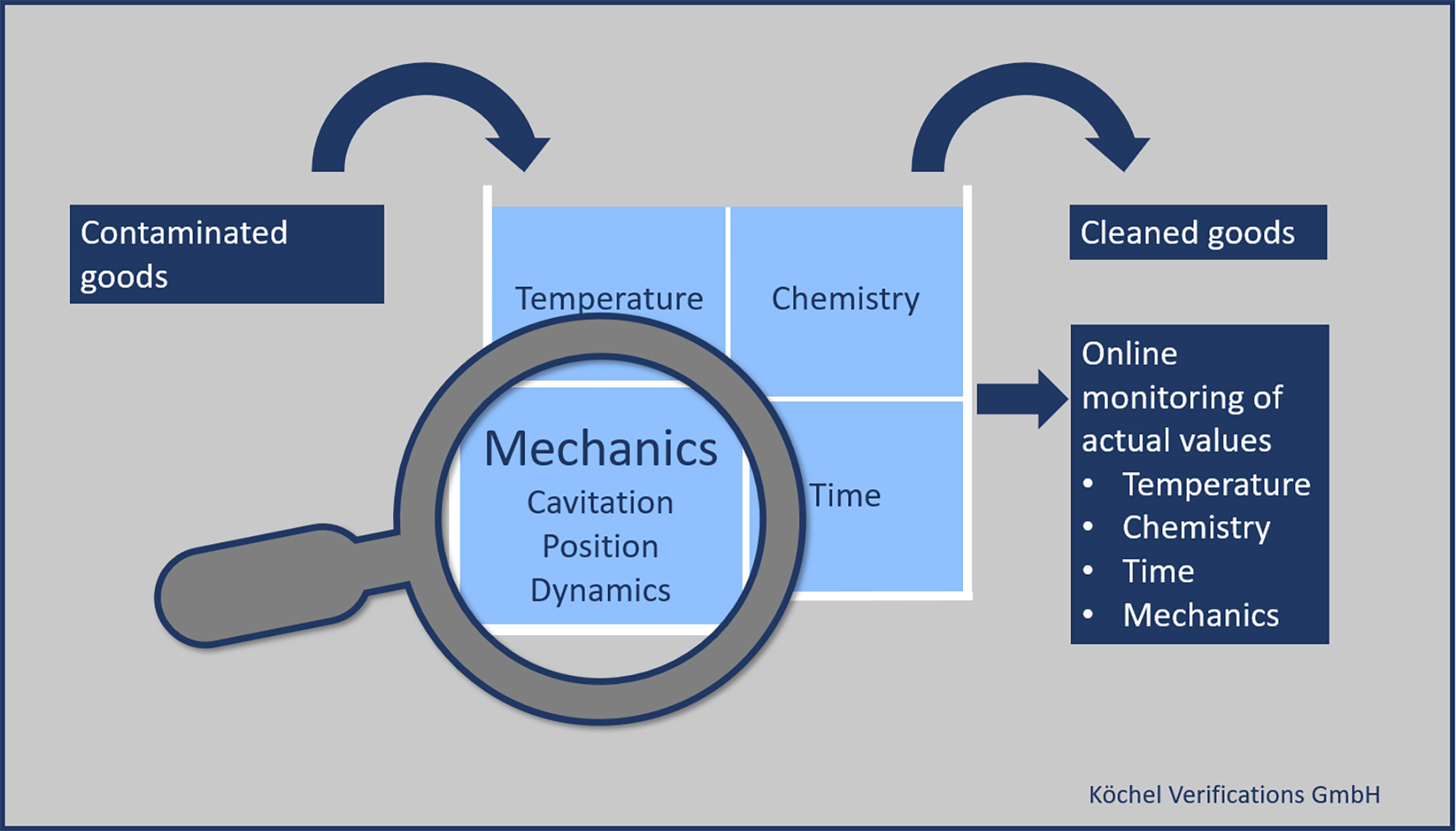

Köchel Verifications: For cleaning, there exist many parameters which are important for the best result. One attempt to visualize these parameters is the Sinner´s circle, which shows the main contributors to cleaning, which are temperature, chemistry, time and mechanics.

All of these components have a major impact on the cleanliness of the product. In ultrasound cleaning, unfortunately, up to now it has been nearly impossible to measure the effect of the mechanics in a quantitative manner. A lot of experts in the market have recognized this problem and ask for a tool to measure the mechanics in their cleaning system.

Cavispector is the first commercial system to measure the cavitation in the ultrasound bath which is responsible for the mechanical effect of the cleaning device.

As mentioned above, cavitation is responsible for the cleaning effect. There, bubbles are generated in the cleaning tank by an ultrasound transducer. When a bubble implodes, a small acoustic shock occurs, which can be measured by an underwater microphone – a hydrophone – as acoustic noise with a wide bandwidth. Normally, many bubbles implode at the same time, and the noise adds’ s up like the clapping of hands in a concert hall. Different studies have shown the correlation of this noise to the mechanical cleaning behaviour in the tank. The measuring method is now standardized in an international technical specification IEC TS 63001, which was published in 2019.

Since this possibility of measurement is quite new to most experts, our goal is to convince them that cavispector is the solution to their problem. More and more customers now rely on cavispector!

E.E: What can you tell us about market trends?

Köchel Verifications: Once users of ultrasound cleaning devices have recognized the advantages of the cavitation measurement with cavispector, they may ask for measurements in a regular manner. When cleaning critical parts, e.g. medical implants, also an online process control should be established which monitors the parameters continuously. This is more or less standard for the measurement of the other parameters of the Sinner´s circle (chemistry, time, temperature). Now we can implement online monitoring also for cavitation. Together with our clients we develop customized solutions which meet their individual needs in measuring and in parameters of the cleaning device.

E.E: What estimations do you have for 2021?

Köchel Verifications: We expect a growing interest in the online measurement of the cavitation in complex cleaning equipment. We have already developed customer specific solutions and we think that online measurement will be a standard in the future.

Due to Covid-19 the market for new cleaning devices and lines was quite depressed in 2020. Now we see a recovery of the investments in new cleaning devices of our potential customers, therefore we also expect a higher volume in our sales.

A personal contact with potential buyers is important for us to present cavispector and to convince them of the advantages of the measurements. Therefore, we hope that the restrictions because of COVID-19 will be eased in 2021 and we can popularize even more our vision: more confidence in ultrasound cleaning.