Kohsel was founded in 1969 and today they produce inductive components for customers all over the world. The company has their own business and production sites across Europe. The quality management system has been ISO 9001 certified since 1995. With +500 employees, Kohsel has the agility, experience, and expertise to effectively prototype and deliver high quality transformers and chokes with built-in know-how.

Kohsel GmbH was founded in 2017 outside Frankfurt to serve German customers.

Interview with Morten Kohsel, Director of Kohsel.

Easy Engineering: What are the main areas of activity of the company?

Morten Kohsel: Our main customers are located in Europa.

E.E: What’s the news about new products?

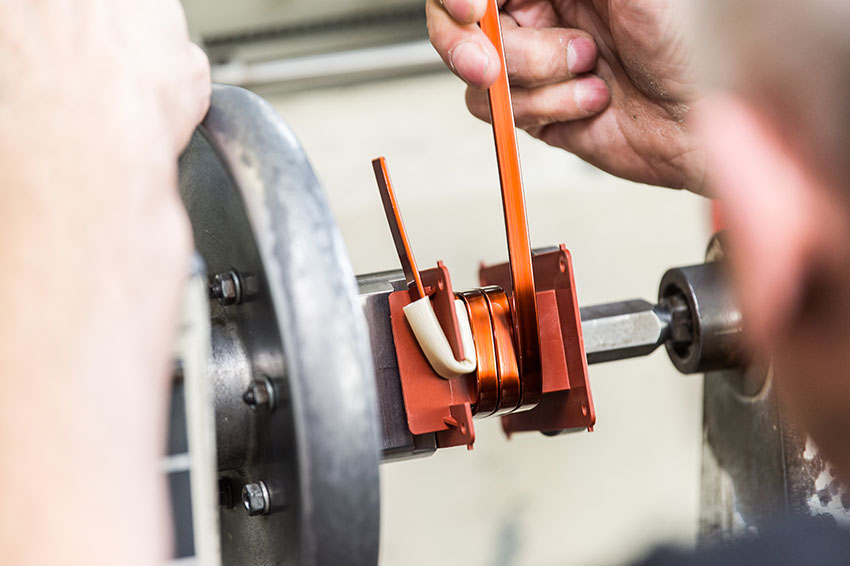

M.K: First of all, I want to enhance the Silicon Carbide topology, which enables a significant increase in voltage and switching frequency, which allows the use of faster, more efficient, and lightweight electrical motors. The higher voltage and frequency generate dV/dt challenges at the output – and you need experience to handle these challenges. Our dV/dt chokes, designed for the Silicon Carbide topology, are compact and silent due to the use of high frequency and low loss core material. Our dV/dt chokes are popular among customers, due to the many benefits when it comes to Silicon Carbide topology.

Water-cooling is another exciting technology to mention in this case. Water-cooling reduces the size of the choke significantly. Our water-cooled chokes are very compact and extremely powerful. They allow excellent efficiency as the heat gradually dissipate through the cooling circuit. This also guarantees a long service life.

E.E: What are the ranges of products?

M.K: Kohsel delivers transformers, chokes and filters primarily for the renewable energy market and for the Greentech market.

E.E: What can you tell us about market trends?

M.K: Kohsel focus on the renewable energy market and on the Greentech market.

Both markets are currently growing strongly due to the increasing focus on sustainability and CO2 reduction.

The wind turbines and the converters inside are constantly getting bigger and this place demands on increasingly efficient liquid cooling of the inductive components.

Within the Power-to-X market, power conversion with Silicon Carbide topology enables a significant increase in voltage and switching frequency. Conversely, it places demands on the inductive chokes and filters.

E.E: What are the most innovative products marketed?

M.K: The most innovative inductive components on the market today are the inductive dV/dt components customized for the Silicon Carbide topology.

E.E: What estimations do you have for 2022?

M.K: Kohsel expects the expansion to continue and we have particularly high expectations for the Power-to-X market and the Greentech market.